Patents

Literature

57 results about "CRESOL/FORMALDEHYDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high softening point o-cresol formaldehyde epoxy resin

InactiveCN102838727AImprove insulation performanceHigh softening pointInksThermal dilatationPolymer science

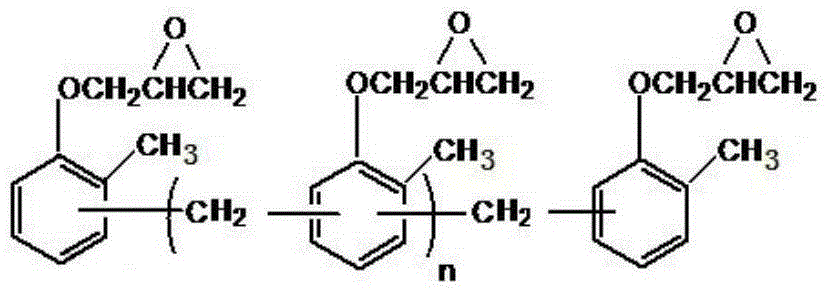

The present invention provides a preparation method for a high softening point o-cresol formaldehyde epoxy resin. The preparation method comprises the following steps: adopting o-cresol and paraformaldehyde as raw materials, carrying out a reaction for 3-5 hours under a catalysis effect of a catalyst, and carrying out a post-treatment to obtain a high softening point o-cresol formaldehyde resin; mixing the synthesized linear high softening point o-cresol formaldehyde resin and epichlorohydrin according to a mass ratio of 1:3-1:10; adding an auxiliary agent; carrying out an etherification reaction at a temperature of 30-100 DEG C; adding an alkali to catalyze a ring closing reaction under a vacuum degree of 0.01-0.1 MPa; recovering the epichlorohydrin; and carrying out a refinement reaction and a post-treatment. The o-cresol formaldehyde epoxy resin prepared by adopting the preparation method of the present invention has the following characteristics that: high softening point of 80-95 DEG C can be achieved; epoxy equivalent is low; hydrolyzable chlorine content is low; and a high yield can be achieved. In addition, the o-cresol formaldehyde epoxy resin of the present invention is a special function type epoxy resin focused for green electronics encapsulation, IC packaging and circuit board (green oil), wherein the o-cresol formaldehyde epoxy resin has characteristics of high heat resistance, low moisture absorption, and low thermal expansion coefficient.

Owner:CHINA PETROCHEMICAL CORP

Novel heat-resistant corrosion-resistant coating as well as preparation and application method thereof

InactiveCN106010229AEvenly paintedStable performanceFireproof paintsAnti-corrosive paintsCorrosion resistantChemistry

The invention provides a novel heat-resistant corrosion-resistant coating as well as a preparation and application method of the novel heat-resistant corrosion-resistant coating, wherein the novel heat-resistant corrosion-resistant coating comprises ethyl silicate, methyl triethoxysilane, triethylamine, ethyl alcohol, hydrochloric acid, o-cresol formaldehyde epoxy resin, dimethylbenzene, diatomite, silica, zinc oxide, zoelite powder, mica, a butyl cellosolve solvent and butyl alcohol. The novel heat-resistant corrosion-resistant coating is reasonable in components, the stability, the corrosion resistance and the heat resistance of a product are good, and the stability is high. The preparation method of the novel heat-resistant corrosion-resistant coating is simple and feasible in process, high in production efficiency and low in application cost, the operation is easy and simple to implement, the quality of a produced product is stable, and the popularization and application values are relatively high.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

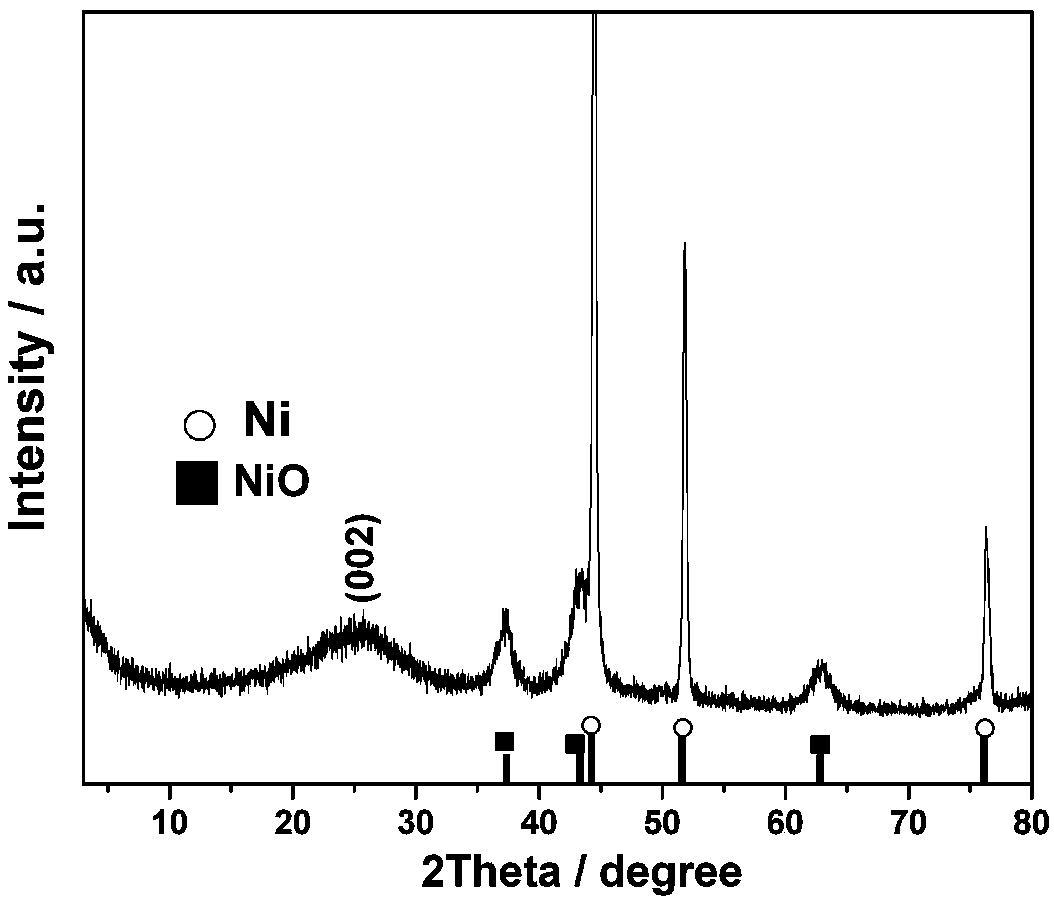

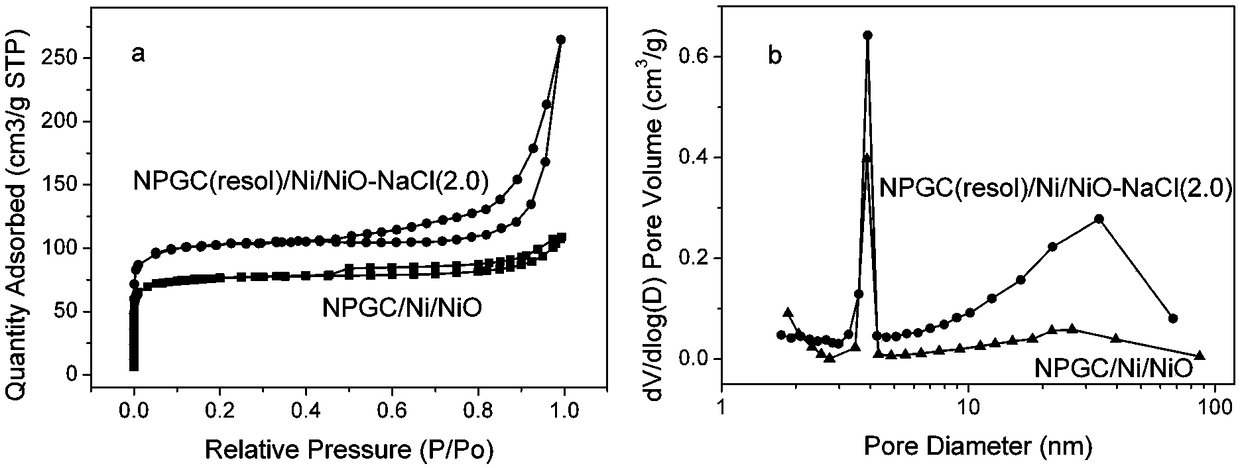

A method for preparing a high specific capacity nanocomposite material by using a dual template

ActiveCN109243853AImprove electrochemical performanceHigh specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCapacitanceNickel salt

The invention belongs to the technical field of energy storage materials, the invention relates to a method for preparing a high specific capacity nano composite material by using a dual- template, Asthat electrode material of the supercapacitor is prepare, the problem of low specific capacitance of composites is not conducive to the application of materials, that is, block copolymer F127 is usedrespectively, As that soft template and the hard template, Combined with the crosslinking reaction of cresol-formaldehyde resin and polyacrylamide, A crosslinked polyacrylamide / nickel salt / sodium chloride aerogel was prepared, after calcination and template removal, In-situ nitrogen doping, carbothermal reduction, catalytic graphitization and formation of high specific capacity three-dimensionalporous structure nitrogen doped carbon / nickel / nickel oxide nanocomposites are realized. The preparation process is simple, the principle is reliable, and the composite has excellent electrochemical performance as the electrode material of supercapacitor, which has good economic benefits and application prospects.

Owner:QINGDAO UNIV OF SCI & TECH

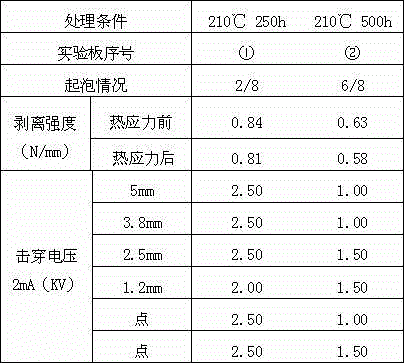

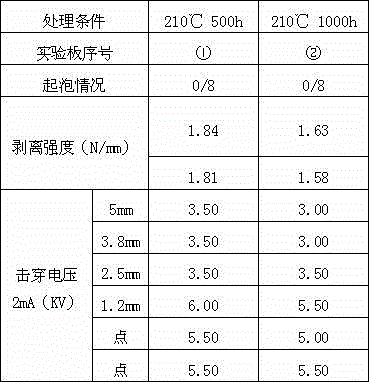

High-temperature-resistant and aging-resistant substrate and production method thereof

InactiveCN104610708AExcellent pyrolysis resistanceReduce liquidityNon-macromolecular adhesive additivesLaminationPolymer scienceInsulation layer

The invention provides a high-temperature-resistant and aging-resistant substrate. The substrate comprises an insulation layer which comprises substances in parts by weight as follows: 1-10 parts of o-cresol formaldehyde epoxy resin, 10-20 parts of phenoxy resin, 20-30 parts of bisphenol A type epoxy resin, 1-10 parts of nitrile butadiene rubber and 30-70 parts of filler. The substrate selects the resin adopting special structures, has excellent high-temperature decomposition resistance, can still keep good mechanical strength and electric strength after treated at the temperature of 210 DEG C for 1000 h and can be adapted to complex using environments such as high-temperature environments and the like.

Owner:广东全宝科技股份有限公司

Light efficient heat protection and insulation integrated thermal protection material and preparation method thereof

The invention discloses a lightweight high-efficiency thermal protection material integrating heat prevention and heat insulation and a preparation method. The thermal protection material is preparedby dipping a heat insulation matrix with organic aerogel, and the heat insulation matrix is a high-temperature-resistant fiber heat insulation tile. The high-temperature-resistant fiber heat insulation tile is made of quartz fiber, mullite, alumina fiber or a combination of the quartz fiber, the mullite and the alumina fiber. The organic aerogel comprises resorcinol and formaldehyde, melamine andformaldehyde, phenolic resin and formaldehyde or mixed cresol and formaldehyde. By adding the organic aerogel into the thermal insulation matrix, the mechanical strength of the thermal insulation material is improved at normal temperature, it is guaranteed that material failure caused by brittle fracture of the material in the machining and transporting processes is avoided; the thermal insulationperformance of the material is improved in the low-temperature application environment, and heat is brought away through ablation volatilization in the high-temperature stage; therefore, normal workof the thermal protection material in a service environment is ensured.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Chip packaging material for computer

InactiveCN104974475AHigh refractive indexHigh hardnessOther chemical processesSemiconductor/solid-state device detailsPhenyl groupMethyl palmoxirate

The invention relates to a chip packaging material for a computer. The chip packaging material comprises the following components, by mass: 15-19 parts of an o-cresol formaldehyde epoxy resin, 6-12 parts of methylene diphenyl diisocyanate, 4-8 parts of vinyltrimethoxy silane, 18-22 parts of phenylvinylsilicone oil, 8-10 parts of a phenyl hydrogen-containing silicon resin, 3-5 parts of ethylene glycol diglycidyl ether, 6-10 parts of methylhexahydrophthalic anhydride, 8-12 parts of poly-p-phenylene terephthalamide, and 8-10 parts of a nanometer vinylmethyl MQ silicon resin. According to the invention, by optimizing the chip packaging material for the computer, the refractive index, hardness, and bonding strength of the chip packaging material for the computer are obviously improved. The chip packaging material, prepared by a method in the invention, for the computer has the shore hardness from 68A to 74A, and the bonding strength from 6.8 MPa to 7.6 MPa.

Owner:龚灿锋

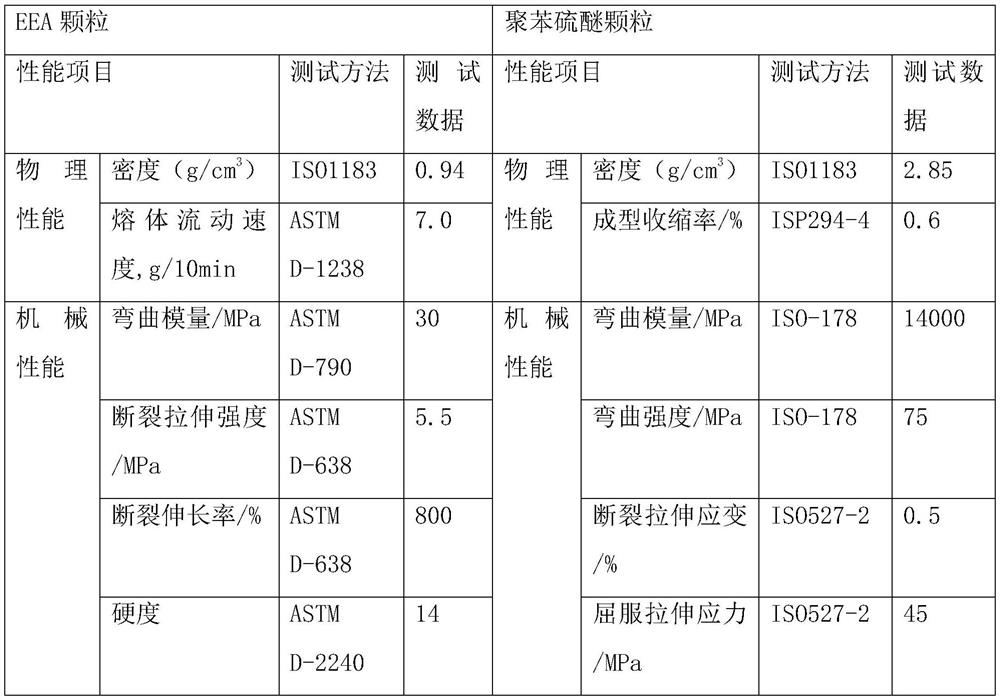

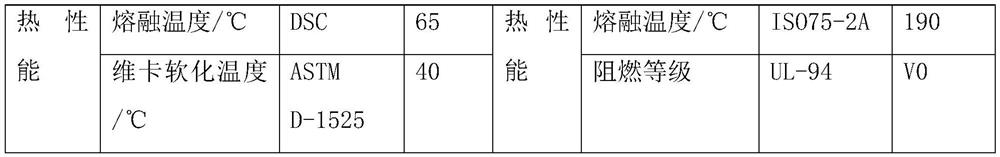

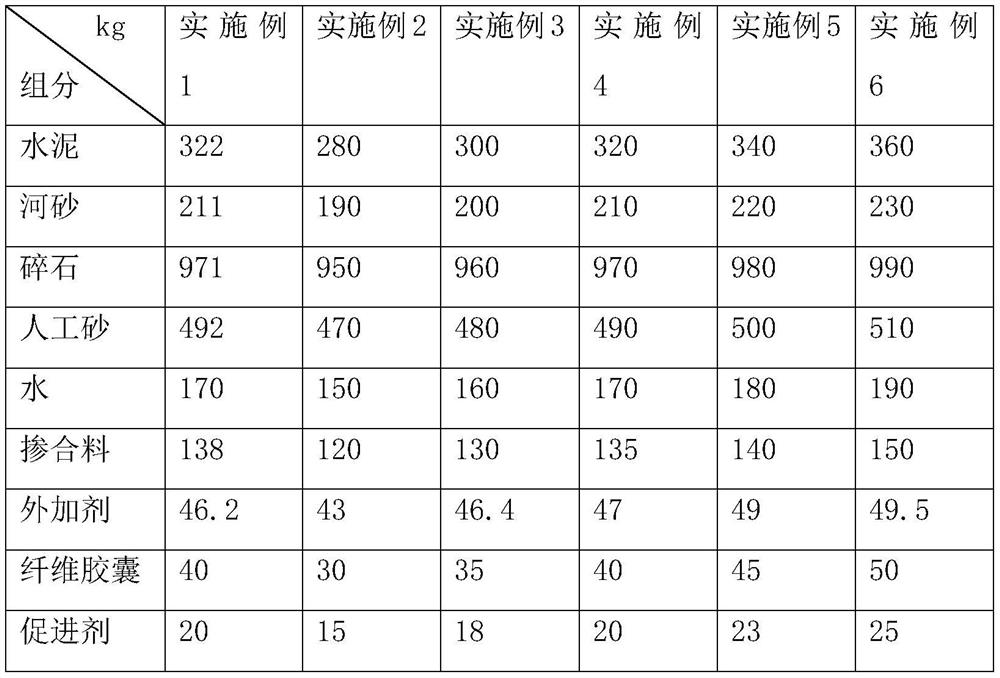

Expansive anti-crack fiber concrete and preparation method thereof

InactiveCN112624694AHigh hardnessHigh strengthFibre typesConjugated synthetic polymer artificial filamentsEpoxyAdhesive cement

The invention relates to the field of building materials, and particularly discloses expansive anti-crack fiber concrete and a preparation method thereof. The expansive anti-crack fiber concrete is prepared from the following components in parts by weight: 280-360 parts of cement, 200-230 parts of river sand, 470-510 parts of artificial sand, 950-990 parts of gravel, 150-190 parts of water, 120-150 parts of an admixture, 43-49.5 parts of an additive, 30-50 parts of a fiber capsule and 15-25 parts of an accelerator. The fiber capsule is prepared by mixing and spray-drying the following raw materials in parts by weight: 1-2 parts of polyphenylene sulfide fiber, 0.5-0.7 part of an alpha-cyanoacrylate adhesive, 0.25-0.3 part of an epoxy resin adhesive and 2-3 parts of an o-cresol formaldehyde epoxy resin. The expansive anti-crack fiber concrete has the advantages that crack repairing can be accelerated, the repairing time is shortened, and when the concrete is damaged again, the expansive anti-crack fiber concrete still has high self-repairing performance.

Owner:青岛光大集团工程有限公司

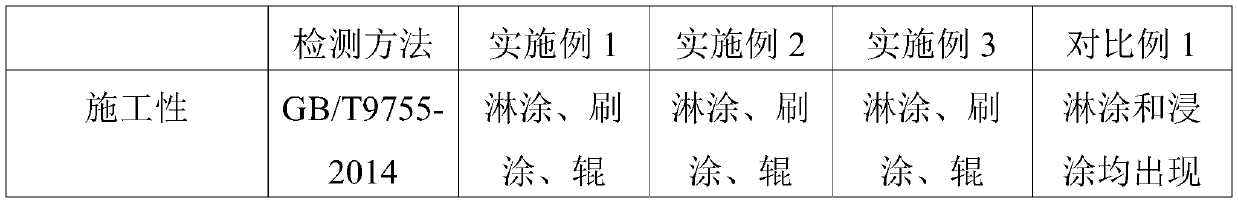

Water-based epoxy coating capable of being subjected to curtain coating and dip coating and preparation method thereof

InactiveCN110643265ALong activation periodHigh mechanical strengthEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to the technical field of coatings, and particularly discloses a water-based epoxy coating capable of being subjected to curtain coating and dip coating and a preparation methodof the water-based epoxy coating. The water-based epoxy coating capable of being subjected to curtain coating comprises a component A and a component B, wherein the component A is prepared from bisphenol A type epoxy resin aqueous dispersion, o-cresol formaldehyde epoxy resin aqueous dispersion, a solvent, a dispersing agent, an anti-settling agent, a wetting leveling agent, a thickener, an antifoaming agent, titanium dioxide, a filler and the balance of deionized water; the component B comprises a water-based amine epoxy curing agent, an environment-friendly solvent and the balance of deionized water, wherein the mass ratio of the component A to the component B is (5-7): 1. The water-based epoxy coating disclosed by the invention is used in the shower coating and dip-coating processes ofcomplex components, and the phenomena of cracking, needle holes and bubbling are avoided.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

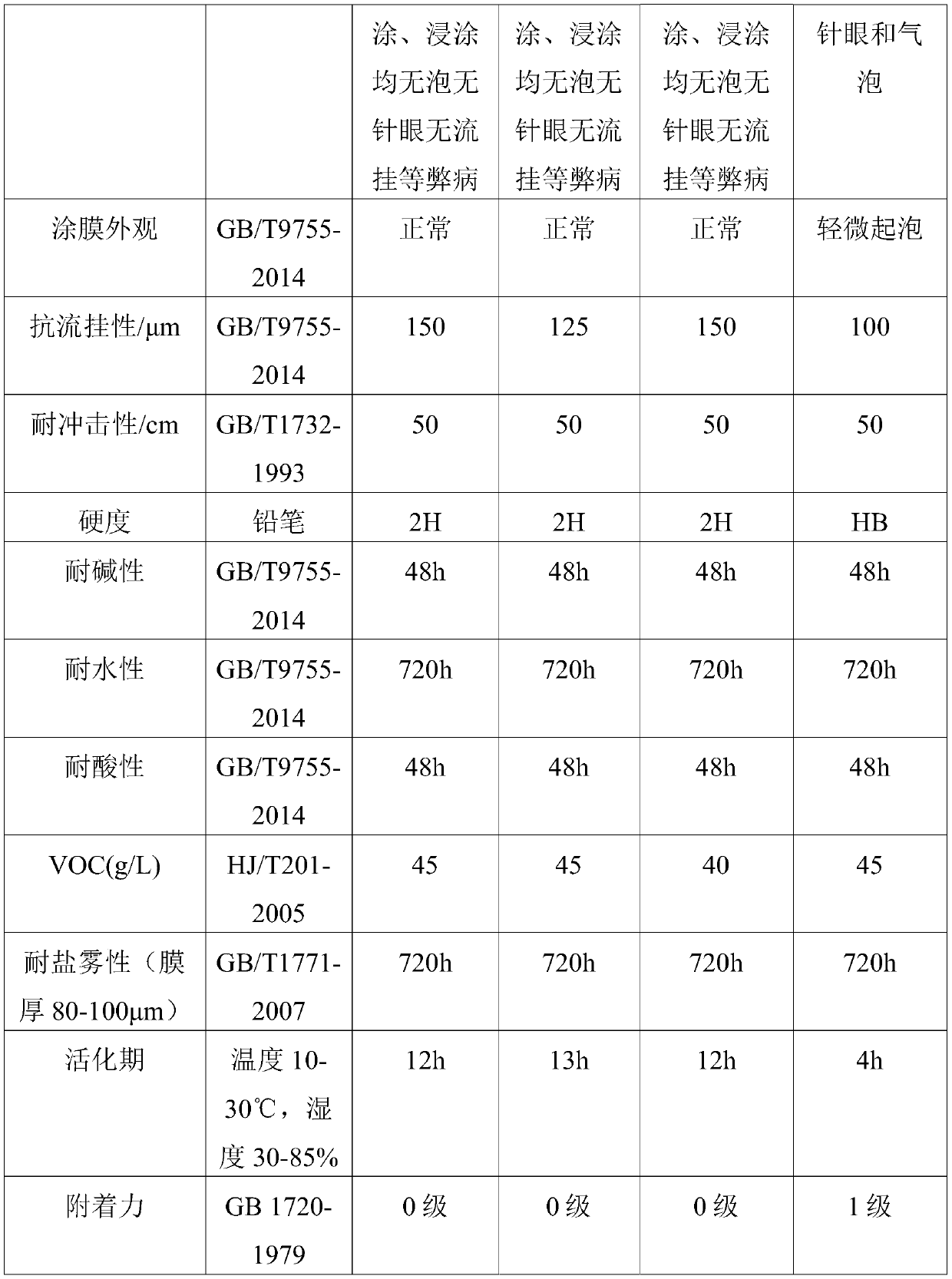

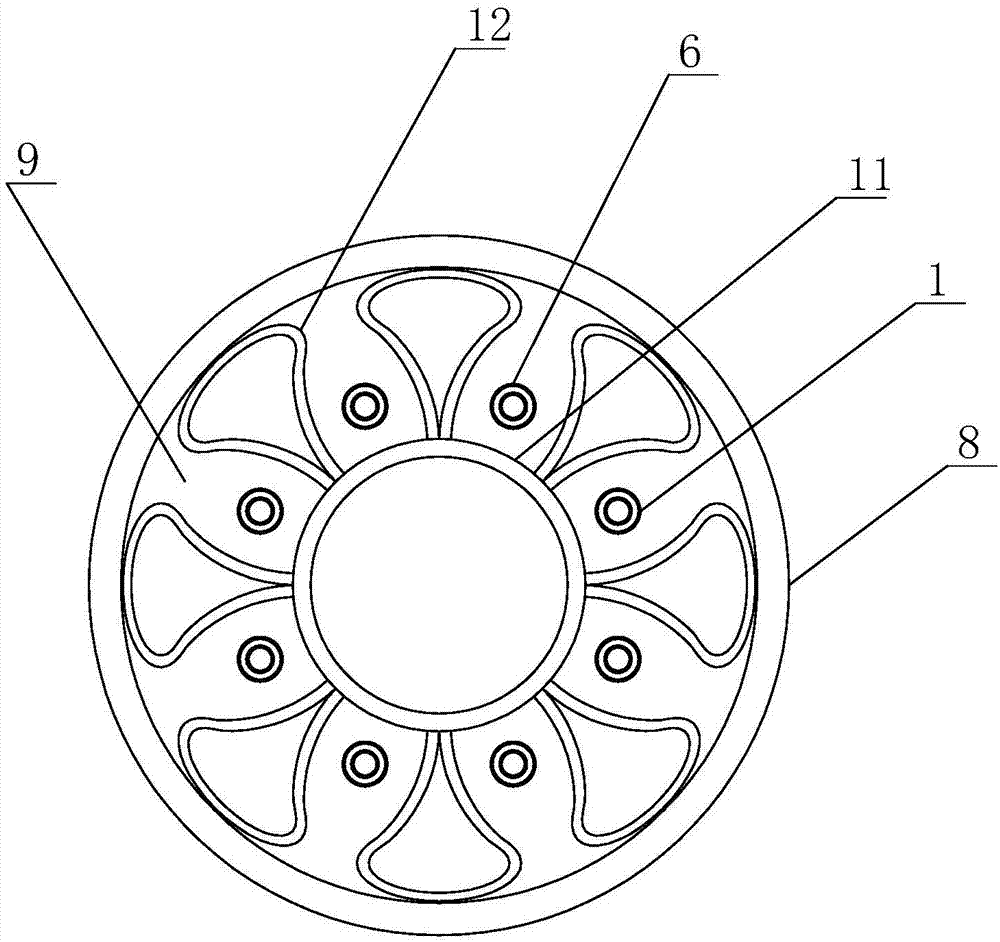

Insulating material for cable insulating layer and underwater composite cable

InactiveCN107118461AGood oil resistanceImprove corrosion resistancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersElectrical conductorPolyvinyl chloride

The invention discloses an insulating material for a cable insulating layer and an underwater composite cable, and mainly relates to the technical field of cables. The insulating material comprises an outer sheath, an armor layer, a waterproof layer and a flame-retardant layer, wherein the flame-retardant layer is internally provided with conductors and coated optical fibers which are distributed alternatively; loose tubes are arranged outside the coated optical fibers; the loose tubes are internally provided with frames; a shielding layer, an insulating layer, an insulating shielding layer, a taped covering and an inner sheath are arranged on the conductor; the insulating layer is made of an insulating material with following raw materials: a PVC (Polyvinyl Chloride) resin, white carbon black, a diphenyl ether resin, an MBS (Methyl Methacrylate) resin, a cresol-formaldehyde resin, a linseed alkyd resin, ethylene-propylene-diene-terpolymer rubber, fatty alcohol-polyoxyethylene ether, calcium stearate, calcined clay and the like. The insulating material has the beneficial effects that protection of the underwater composite cable is remarkably improved, the properties of the insulating material and the insulating layer are optimized and improved, and construction and use requirements of the underwater composite cable are met.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO +1

Aerogel modified LED-UV scalding-resistant paint and preparation method and using method thereof

InactiveCN109575759AEasy to useImprove heat resistanceFireproof paintsLiquid surface applicatorsAcrylic resinSlurry

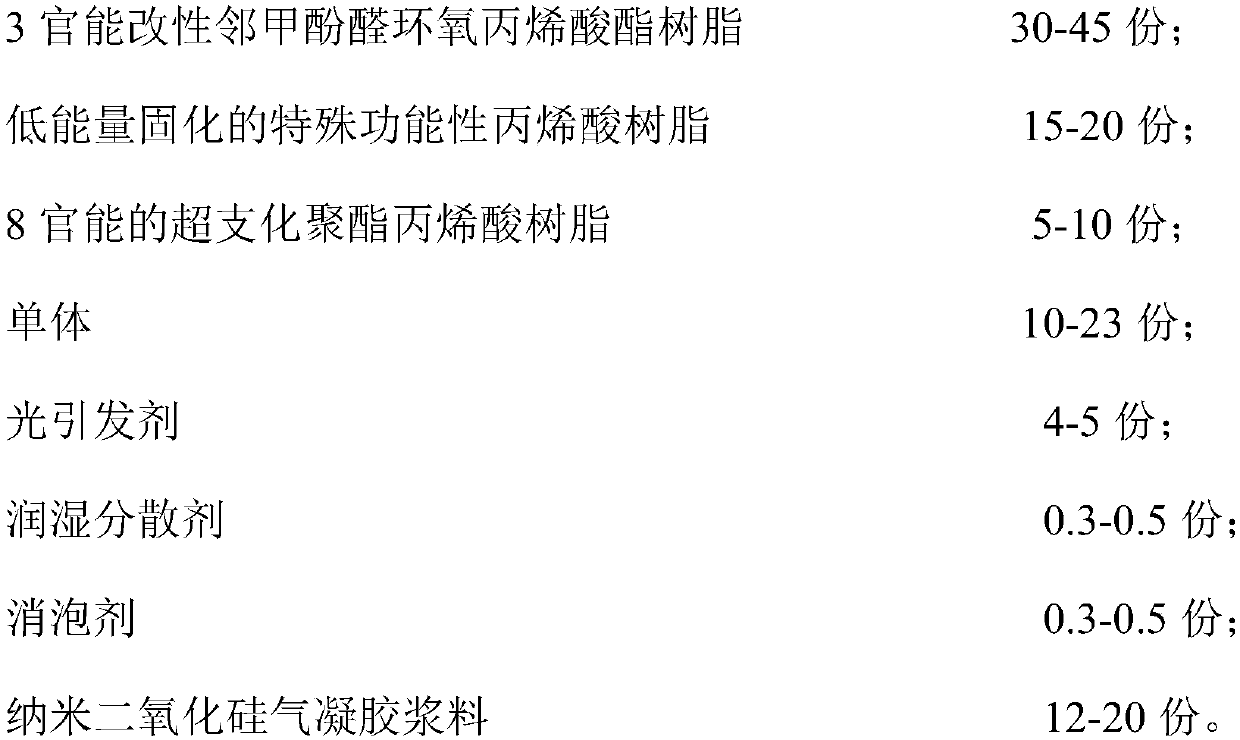

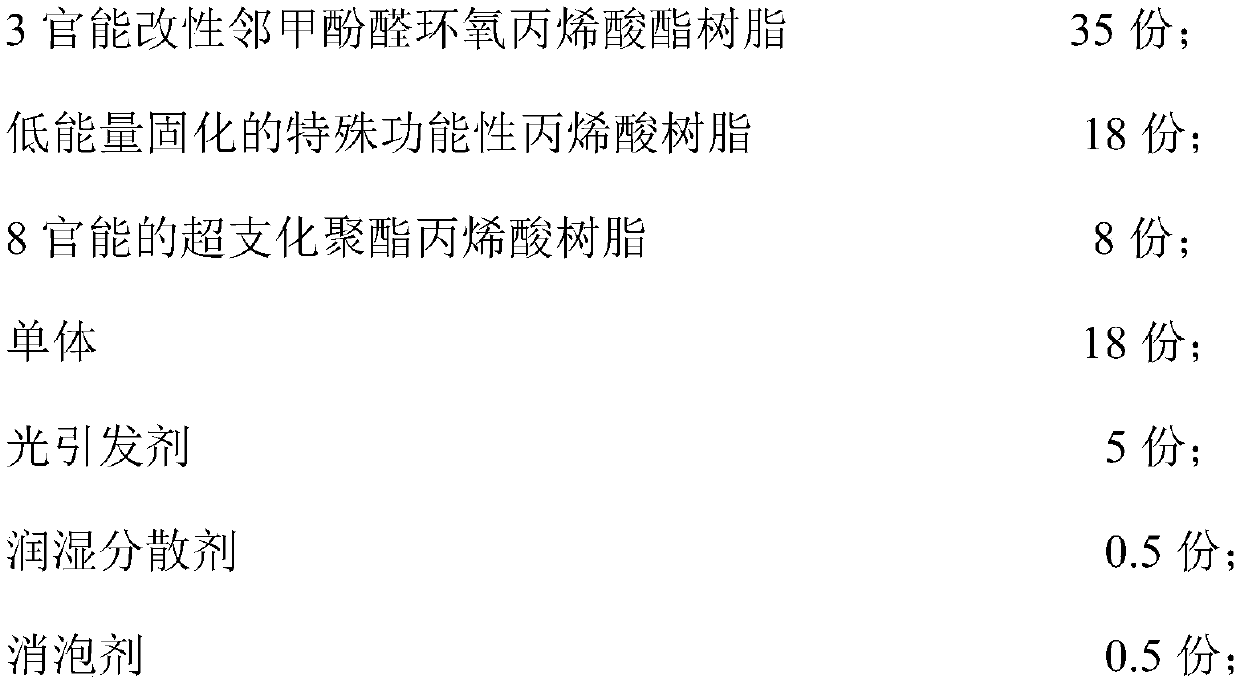

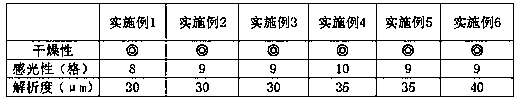

The invention provides an aerogel modified LED-UV scalding-resistant paint which is obtained by mixing, by weight, 30-45 parts of 3 functional modified O-cresol formaldehyde epoxy acrylate resin, 15-20 parts of low-energy-curing special functional acrylic resin, 5-10 parts of 8 functional hyperbranched polyester acrylic resin, 10-23 parts of monomer, 4-5 parts of photoinitiator, 0.3-0.5 part of wetting dispersant, 0.3-0.5 part of defoamer and 12-20 parts of nano silicon dioxide aerogel slurry. The LED-UV paint is high in low-energy curing efficiency, environment-friendly, free of VOC emission,convenient in construction and good in heat-resistant and scalding-resistant performance; a LED-UV lamp is used in the process of curing and drying of the paint, and an obtained film is high in hardness, high in resistance to heat and scalding, smooth in surface and good in hand feel. The invention further provides a preparation method and a using method of the LED-UV scalding-resistant paint.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

High-resolution solder resist ink

InactiveCN111100499AHigh refractive indexReduce photosensitivityInksPhotosensitive materials for photomechanical apparatusPolymer sciencePhotopigment

The invention relates to high-resolution solder resist ink. The high-resolution solder resist ink is characterized by being prepared from the following components in parts by mass: 25-45 parts of o-cresol formaldehyde epoxy acrylate resin, 25-30 parts of high-refractive-index inorganic filler, 5-8 parts of high-refractive-index photocuring monomer, 2-5 parts of a photoinitiator, 0.5-1.5 parts of an amine curing agent, 5-10 parts of epoxy resin, 4-6 parts of triglycidyl isocyanurate, 10-15 parts of a solvent, 0-3 parts of a defoamer, 0-3 parts of a leveling agent, 0-3 parts of a stabilizer and0-3 parts of a pigment. The high-resolution solder resist ink has the advantages of the large refractive index and the low refraction angle, and can reduce the photosensitivity of the non-exposure area, thereby reducing the burrs and enhancing the resolution.

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

Insulated cable and preparation method thereof

InactiveCN105551692AHigh insulation resistanceEasy to preparePlastic/resin/waxes insulatorsInsulating conductors/cablesEpoxyCalcium biphosphate

The invention discloses an insulated cable and a preparation method thereof; the insulated cable comprises a cable core and an insulated layer; the insulated layer is coated outside the cable core; the preparation method comprises the following steps: 1) mixing bisphenol F epoxy resin, cresol-formaldehyde resin, phenolic resin powder, lubricant, silicon dioxide, cryolite, magnesium hydroxide, diethyl malonate and calcium phosphate to obtain a mixture; and 2) coating the mixture outside the cable core by extrusion molding to obtain the insulated cable. The insulated cable prepared with the method has excellent insulation performance, the preparation method is simple and the raw materials are easily available.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

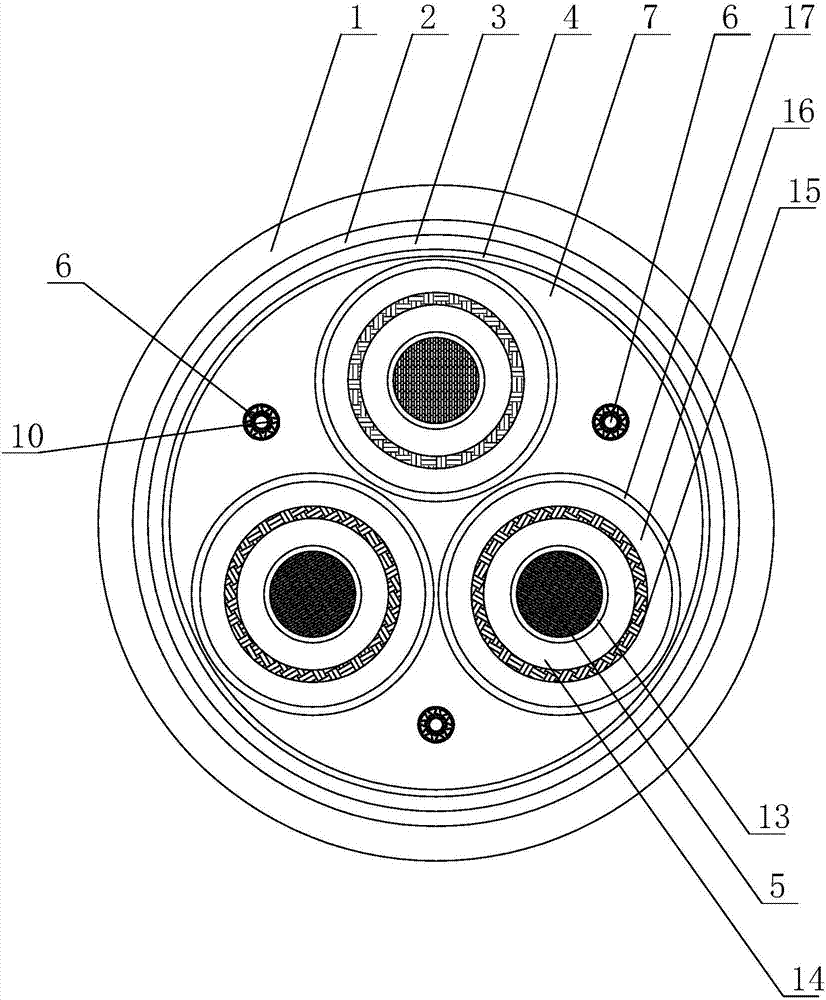

Method for preparing polyformaldehyde nascent fibers

ActiveCN105177756AInhibition of crystallinityImprove performanceArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentEpoxyFiber

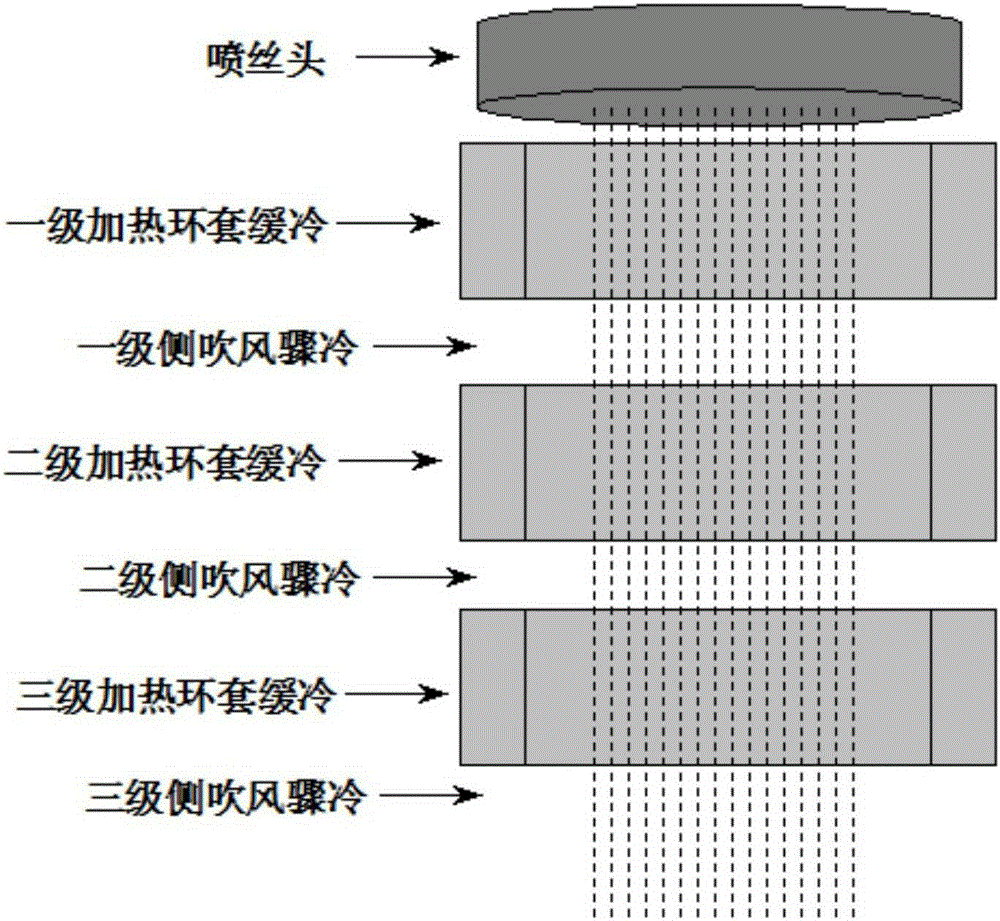

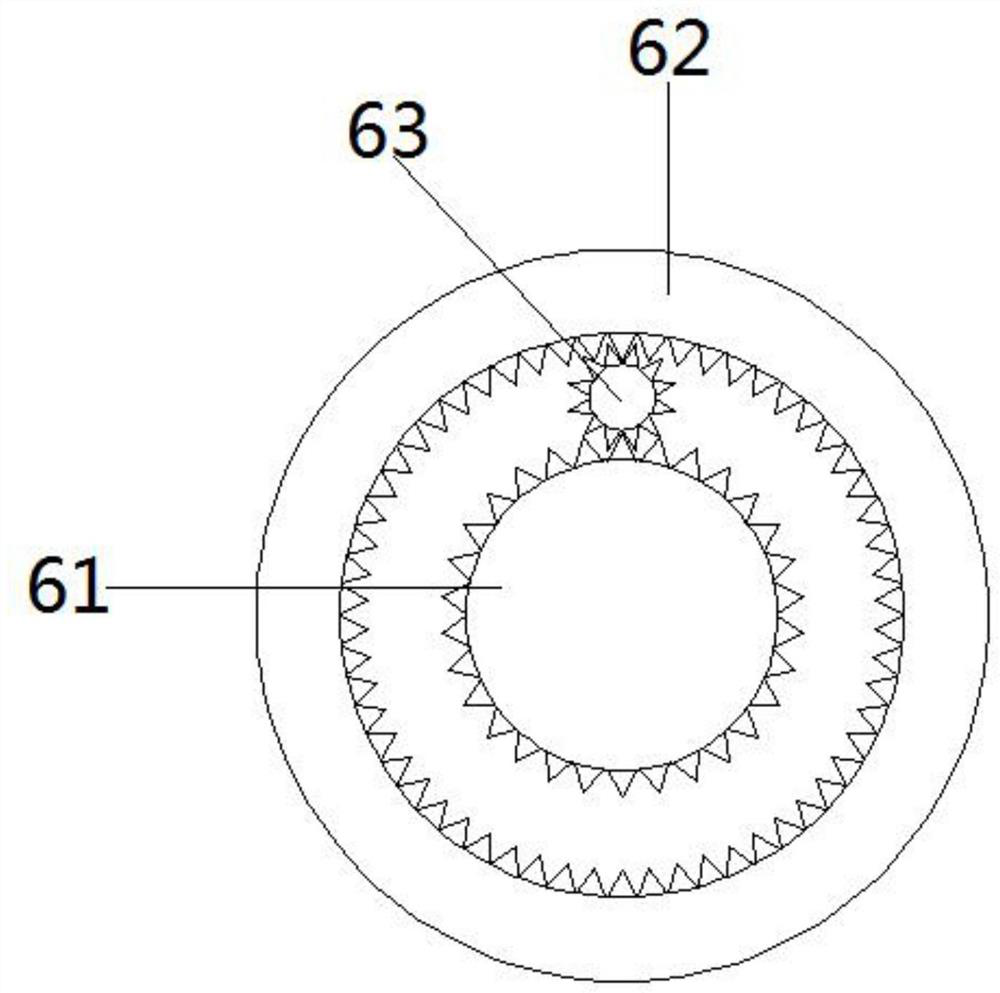

The invention discloses a method for preparing polyformaldehyde nascent fibers. The method includes the specific steps that polyformaldehyde resin and a small amount of o-cresol formaldehyde epoxy resin are evenly mixed and then placed into a vacuum drying box to be dried; the dried mixed materials are heated and fused in a screw extruder; spinning is carried out through a spinning assembly, spun filaments pass through a stage-by-stage slow-cooling and shock-cooling device (please see a figure in the specification) and are naturally cooled, then oil applying clustering and winding are carried out, and the nascent fibers are obtained. By means of the preparing method, the crystallinity of polyformaldehyde is effectively inhibited, the crystallization speed of the polyformaldehyde is decreased, good spinnability is given to the polyformaldehyde resin, the defects of broken filaments, surface micropores and the like generated in the multi-rate stretching process of the fibers are reduced, finished fibers obtained after the nascent fibers are stored for a period of time and then subjected to hot-air slow pulling processing are excellent in performance, the implementing method is simple, and production cost is low.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

High-insulation switch shell and preparation method thereof

InactiveCN105255104AImprove mechanical propertiesImprove insulation performancePropionateCalcium biphosphate

The invention discloses a high-insulation switch shell and a preparation method thereof. The preparation method comprises the steps that 1, mixing is performed on phenolic resin, cresol-formaldehyde resin, cellulose propionate, talcum powder, calcium stearate, white carbon black, diethyl malonate and calcium phosphate to prepare mixing matter; 2, extrusion molding is performed on the mixing matter to prepare the high-insulation switch shell. The high-insulation switch shell prepared through the method has the excellent mechanical property and anti-insulation property; in addition, the preparation method is simple, and the raw materials are easy to obtain.

Owner:芜湖龙峰电器电子有限公司

High-temperature-resistant epoxy adhesive tape and preparation method thereof

PendingCN113956820AHigh water contact angleImprove waterproof performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

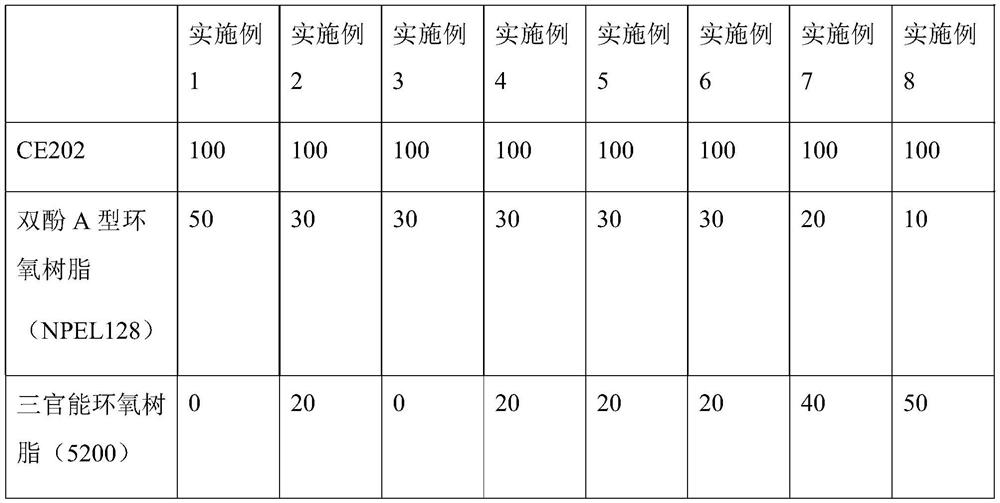

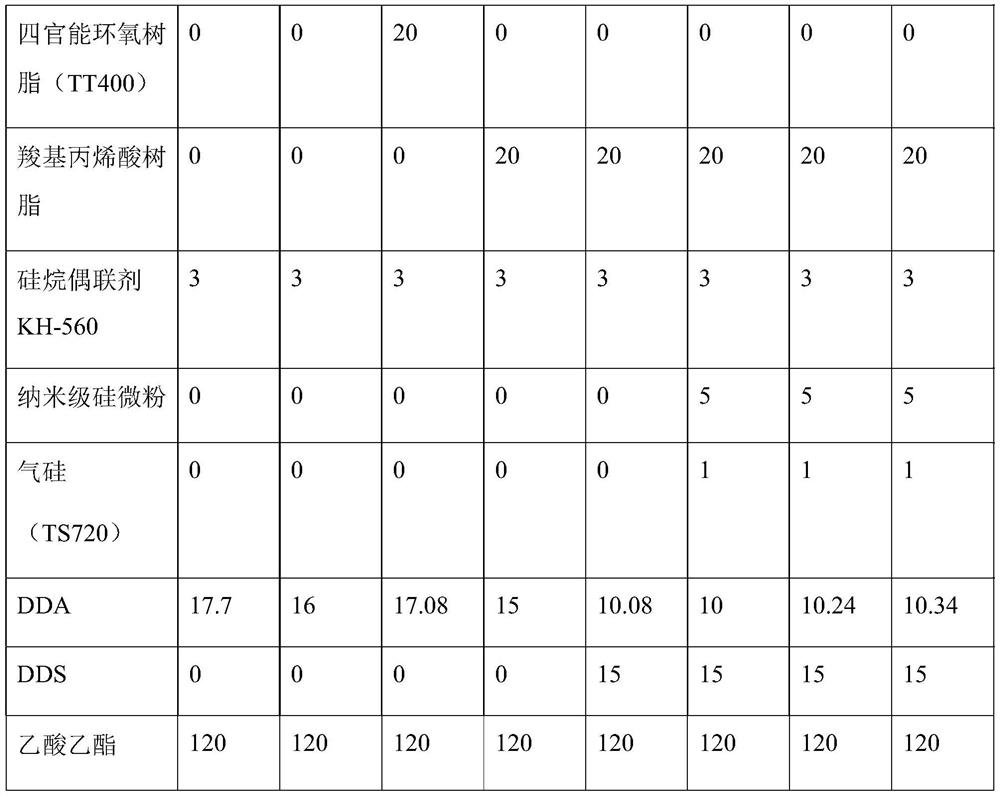

The invention discloses a high-temperature-resistant epoxy adhesive tape and a preparation method thereof. The high-temperature-resistant epoxy adhesive tape comprises a release film and a high-temperature-resistant epoxy adhesive film, wherein the release film and the high-temperature-resistant epoxy adhesive film are laminated. The preparation method comprises the steps of S1, dissolving o-cresol formaldehyde epoxy resin in ethyl acetate, adding carboxyl acrylic resin, high-functional epoxy resin, bisphenol A epoxy resin, a silane coupling agent, a curing agent and filler, and uniformly mixing to obtain a mixed glue solution; and S2, filtering the mixed glue solution, coating one side of a release film with the mixed glue solution, drying to form a high-temperature-resistant epoxy glue film, coating the other side of the high-temperature-resistant epoxy glue film with the release film, and cutting to obtain the high-temperature-resistant epoxy adhesive tape. The prepared high-temperature-resistant epoxy adhesive tape solves the problems that a traditional acrylic acid adhesive tape is complex in production process, large in peculiar smell and insufficient in temperature resistance. The problems that a traditional two-component temperature-resistant adhesive for bonding structural parts is inconvenient to use and prone to glue overflowing are solved, and the adhesive tape has high temperature resistance and still keeps good mechanical strength under a high-temperature condition.

Owner:世晨材料技术(上海)有限公司

Graphene RFID electronic tag suitable for gravure printing method preparation

ActiveCN113789082AImprove mobilityTransfer in timeInksRecord carriers used with machinesEpoxyToluene diisocyanate

The invention relates to the technical field of RFID electronic tags, and particularly provides a graphene RFID electronic tag suitable for gravure printing method preparation. The graphene RFID electronic tag comprises a base material and graphene conductive paste printed on the base material by adopting the gravure printing method. The graphene conductive paste comprises the following components in parts by weight: 5-10 parts of graphene, 1-3 parts of a surfactant, 5-10 parts of a dispersant, and 15-25 parts of cured resin. The cured resin is prepared from o-cresol formaldehyde epoxy resin, polyurethane, methyl tetrahydrophthalic anhydride, trimethylolpropane and toluene-2,4-diisocyanate in the mass ratio of (70-90):(10-30):(18-23):(1.8-5.5):(0.5-1.6). The surfactant is prepared from sodium dodecyl benzene sulfonate and sodium alcohol ether sulphate according to the mass ratio of (0.5-0.8):(1.2-1.5). The graphene slurry provided by the invention is dispersed in the cured resin in the presence of the specific surfactant, and is supplemented with the specific dispersant and the auxiliary agent to prepare the printing slurry, and the printing slurry is used for resisting static electricity when an RFID electronic tag is prepared by an intaglio printing technology.

Owner:SHANDONG HUAGUAN SMART CARD

Flexible environment-friendly high-temperature-resistant protective film and preparation method thereof

ActiveCN111647188AReduce heat gainImprove densification performanceChloropene polymer coatingsPolyether coatingsIr reflectionAdhesive

The invention relates to the technical field of film manufacturing, in particular to a flexible environment-friendly high-temperature-resistant protective film and a preparation method thereof. The protective film includes a basic core layer and an infrared reflective layer and is prepared from following raw materials: aromatic polyamide fiber, nano copper oxide, nano zinc sulfide, perfluoroalkylpolyether, phenolic resin modified chloroprene rubber adhesive, polytetrafluoroethylene, polybenzimidazole fiber, basalt fiber, nano silicon dioxide, epichlorohydrin rubber, o-cresol formaldehyde epoxy resin, methyl silicone rubber, polyurethane modified epoxy resin and sulfur trioxide. The film disclosed by the invention is subjected to multi-layer treatment, so that the whole film is clear in hierarchy and the heat conduction effect can be reduced; the heat absorption of the whole film can be reduced through multi-layer reflection of external radiation, and the film has better high-temperature tolerance and heat insulation effect, good manufacturing link and environmental compatibility and better environmental suitability.

Owner:安徽省六麦新材料科技有限公司

Environment-friendly type building insulation sheet material and preparation method thereof

The invention discloses an environment-friendly type building insulation sheet material and a preparation method thereof. The preparation method of the building insulation sheet material comprises the following steps: 1) taking perlite, polymerization alumina, calcium boride and magnesium nitride, respectively performing ball milling on the above components in a ball mill; 2) respectively weighing the following components in parts by weight: 8-15 parts of o-cresol formaldehyde epoxy resin, 4-10 parts of polyvinylidene fluoride, 6-12 parts of rigid polyurethane foam, 3-6 parts of perlite, 4-9 parts of polymerization alumina, 4-8 parts of calcium boride, 2-6 parts of magnesium nitride and 5-10 parts of polymethacrylimide, mixing the above components to an uniform state; and 3) compacting the uniformly mixed insulation material and moulding to obtain the environment-friendly type building insulation sheet material. The environment-friendly type building insulation sheet material has the characteristics of high compressive strength, high breaking strength and good thermal insulation performance.

Owner:苏州书瑞环保科技有限公司

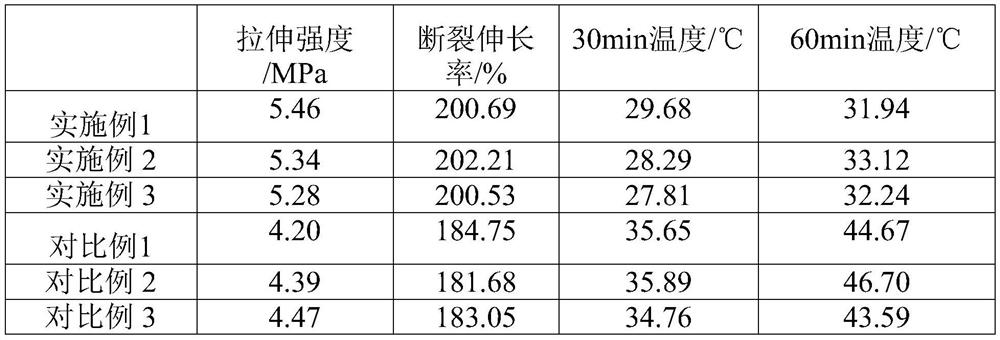

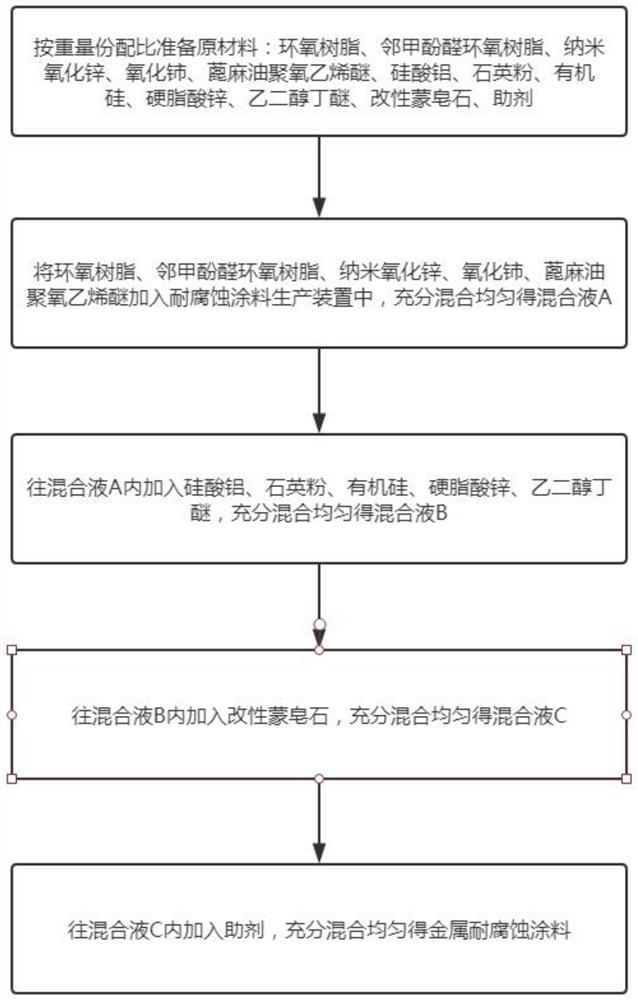

Metal corrosion-resistant coating material for electrical equipment maintenance and preparation method of metal corrosion-resistant coating material

InactiveCN112898861AReduce maintenance frequencyPrevent rustRotating receptacle mixersTransportation and packagingEpoxyCrack resistance

The invention discloses a metal corrosion-resistant coating material for electrical equipment maintenance and a preparation method of the metal corrosion-resistant coating material, belongs to the technical field of electrical equipment maintenance, and provides a metal corrosion-resistant coating material for electrical equipment maintenance and a preparation method of the metal corrosion-resistant coating material. According to the invention, the coating material comprises an epoxy resin, o-cresol formaldehyde epoxy resin, nano-zinc oxide, cerium oxide, castor oil polyoxyethylene ether, quartz powder, organic silicon, zinc stearate, ethylene glycol butyl ether, an auxiliary agent and other components, can achieve excellent rust resistance, wear resistance, corrosion resistance and crack resistance, and is uniform and compact in film layer and good in surface smoothness; after the surface of a shell of power equipment is coated with the coating material, the shell can be effectively prevented from rust, and the maintenance frequency of the electrical equipment is reduced; and modified smectite is added, and in the preparation process of the modified smectite, fluotitanic acid can change the structure and the pore channel of the smectite so as to increase the phosphorus powder adsorption amount of the smectite, that the metal stabilizing performance of the modified smectite is substantially improved, and the corrosion resistance and the crack resistance of the metal corrosion-resistant coating material are further improved.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO

Preparation method of high-thermal-conductivity epoxy molding compound

The invention discloses a preparation method of a high-thermal-conductivity epoxy molding compound, and belongs to the technical field of microelectronic packaging. Serpentine is subjected to activation and acid leaching through calcination to be subjected to impurity removal, the serpentine is mixed with methyl alcohol, dicyclopentadiene and the like, then, the mixture is placed into a reaction kettle to be subjected to laser irradiation for a reaction, the surface of the mixture is modified, the high thermal conductivity is improved, finally, the mixture is subjected to ball milling mixing with o-cresol formaldehyde epoxy resin, carbon black, triethylene tetramine and the like, and extrusion granulation is performed to obtain the high-thermal-conductivity epoxy molding compound. The serpentine is adopted as the raw material, the serpentine is modified to form a filler, and therefore the defect that due to the fact that the heat conductivity of a traditional molding compound is not high, the thermal shock resistance under the high-temperature condition is not good is overcome; the preparation method has wide production prospects.

Owner:袁春华

Binder used for varnished wire of transposed conductor wire

InactiveCN105623594AReduced risk of deformationNon-macromolecular adhesive additivesXylylenePolymer science

The present invention discloses a binder used for a varnished wire of a transposed conductor wire and a production method thereof, and the binder is mainly prepared by use of polyvinyl butyral, cresol formaldehyde resin, hydrochloric acid, ethanol, butanol, xylene and aminopropyltriethoxysilane silane through heating, melting, condensation and other steps. According to the binder used for the varnished wire of the transposed conductor wire and the production method thereof, when a winding group is prepared from the transposed conductor wire, in the drying molding process, the times of melting can be set as once or twice, and after the production is complete, the binder may be permanently solidified. Ultra high temperature melting produced by a transformer winding subjected to short-circuit impacts can be resisted, the binding power of the transposed conductor wire is lost, and mechanical strength and the risk of occurrence of deformation can be reduced.

Owner:STATE GRID CORP OF CHINA +1

Halogen-containing high-Tg high-speed copper-clad plate for communication server and preparation method thereof

InactiveCN114274618AExcellent dielectric propertiesGood dielectricSynthetic resin layered productsGlass/slag layered productsPolymer scienceTetrabromobisphenol A

The invention discloses a halogen-containing high-Tg high-speed copper-clad plate for a communication server and a preparation method of the halogen-containing high-Tg high-speed copper-clad plate, and belongs to the technical field of 5G copper-clad plates and production processes thereof. The copper-clad plate comprises a bottom copper foil layer, a top copper foil layer and an insulating medium layer which is positioned between the bottom copper foil layer and the top copper foil layer and is formed by laminating 1-8 prepregs, and each prepreg is obtained by soaking glass fiber cloth in a resin glue solution and then drying, wherein the resin glue solution comprises styrene-maleic anhydride copolymer resin, tetrabromobisphenol A, cyanate ester, modified epoxy resin and silicon dioxide filler, and the modified epoxy resin is formed by mixing brominated epoxy resin, cresol formaldehyde epoxy resin, linear novolac epoxy resin and bisphenol A epoxy resin according to a specific proportion. The prepared copper-clad plate has the characteristics of high glass transition temperature, high heat resistance, low thermal expansion coefficient, low dielectric constant, low dielectric loss, good dimensional stability and the like.

Owner:江苏联鑫电子工业有限公司

O-cresol formaldehyde epoxy resin, preparation method and application thereof

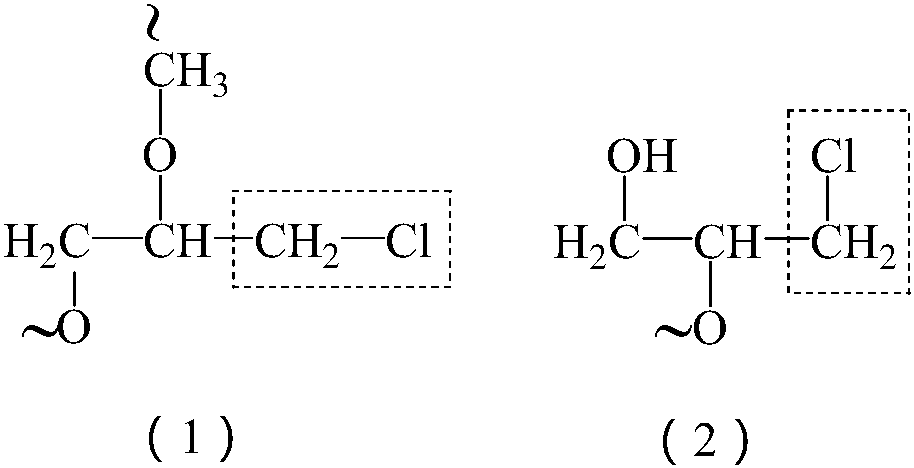

ActiveCN109776762AReduce chlorine contentImprove reaction efficiencySemiconductor/solid-state device detailsSolid-state devicesEpoxySolvent

The invention discloses a preparation method of an o-cresol formaldehyde epoxy resin. The preparation method is characterized by comprising the steps of pre-reacting an o-cresol-formaldehyde resin, epichlorohydrin and an alkali A to obtain a pre-reaction liquid; mixing a crown ether and an alkali B to obtain a mixed liquid; then adding the mixed liquid to the pre-reaction liquid to carry out a catalytic ring-closing reaction; after the ring-closing reaction is completed, removing the epichlorohydrin first, then performing a refining reaction, washing, and removing a solvent to obtain the product. The o-cresol formaldehyde epoxy resin synthesized by the method is low in non-hydrolyzable chlorine content and meets the requirement of high-end products of the electronic molding compound industry for the o-cresol formaldehyde epoxy resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of adsorption process in synthesis of o-cresol formaldehyde epoxy resin

The invention discloses application of an adsorption process in o-cresol formaldehyde epoxy resin synthesis. The process comprises the following steps: 1, dissolving o-cresol formaldehyde resin in anorganic solvent, adding epoxy chloropropane and a reducing agent, and carrying out heating to perform a reductive decolorization reaction; 2, adding a phase transfer agent and a cocatalyst into the reaction system having undergone the reductive decolorization reaction, and carrying out reduced-pressure reflux for an etherification reaction to obtain an etherification reaction product; 3, adding abase catalyst into the etherification reaction product for a ring-closure reaction; and 4, filtering the reaction system having undergone the ring-closure reaction to obtain a feed liquid, subjectingthe feed liquid to adsorption with an adsorbent, carrying out washing with water, and carrying out reduced-pressure distillation to obtain the o-cresol formaldehyde epoxy resin. According to the method, the adsorbent is used for adsorbing the reaction system feed liquid after the ring-closure reaction, so the content of impurities in the liquid after adsorption is reduced, subsequent washing efficiency is improved, washing time is shortened, the phenomenon of emulsification is reduced, the chromaticity of the o-cresol formaldehyde epoxy resin is reduced, and the low chlorine content of the o-cresol formaldehyde epoxy resin is ensured.

Owner:XIAN ORIGIN CHEM TECH

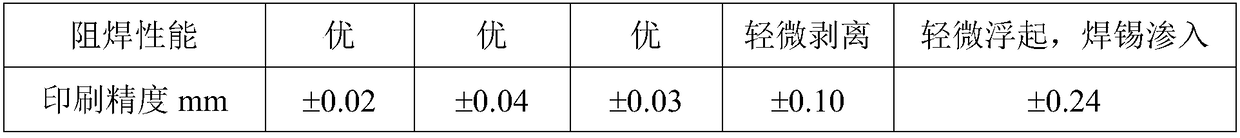

Liquid development white photoimageable ink and preparation method thereof

InactiveCN108530987AShort curing timeImprove printing accuracyInksPhotosensitive materials for photomechanical apparatusPhotoinitiatorMulti element

The invention discloses liquid development white photoimageable ink and a preparation method thereof. The liquid development white photoimageable ink comprises, by weight, 30-45 parts of multi-elementanhydride modified linear phenolic epoxy acrylate, 10-20 parts of acrylic acid active monomer, 5-10 parts of photoinitiator, 3-8 parts of titanium dioxide, 2-5 parts of barium sulfate, 2-6 parts of fluorine-containing surfactant, 1-3 parts of defoaming agent, 1-3 parts of water reducing agent and 1-3 parts of leveling agent. The liquid development white photoimageable ink and the preparation method thereof have the advantages that multi-element phthalic anhydride is used to modify o-cresol formaldehyde epoxy acrylate to obtain the multi-element anhydride modified linear phenolic epoxy acrylate, the multi-element anhydride modified linear phenolic epoxy acrylate is small in thermal expansion coefficient, stable in dimension, high in softening temperature and capable of guaranteeing the cold dryness of a substratum before exposure, and accordingly the precision of circuit board printing is increased.

Owner:江苏海田电子材料有限公司

Glue solution for halogen-free medium-Tg medium-loss copper-clad plate as well as preparation method and application of the glue solution

InactiveCN112048155AImprove defectsHigh glass transition temperatureSynthetic resin layered productsMetal layered productsPolymer scienceO-Cresol

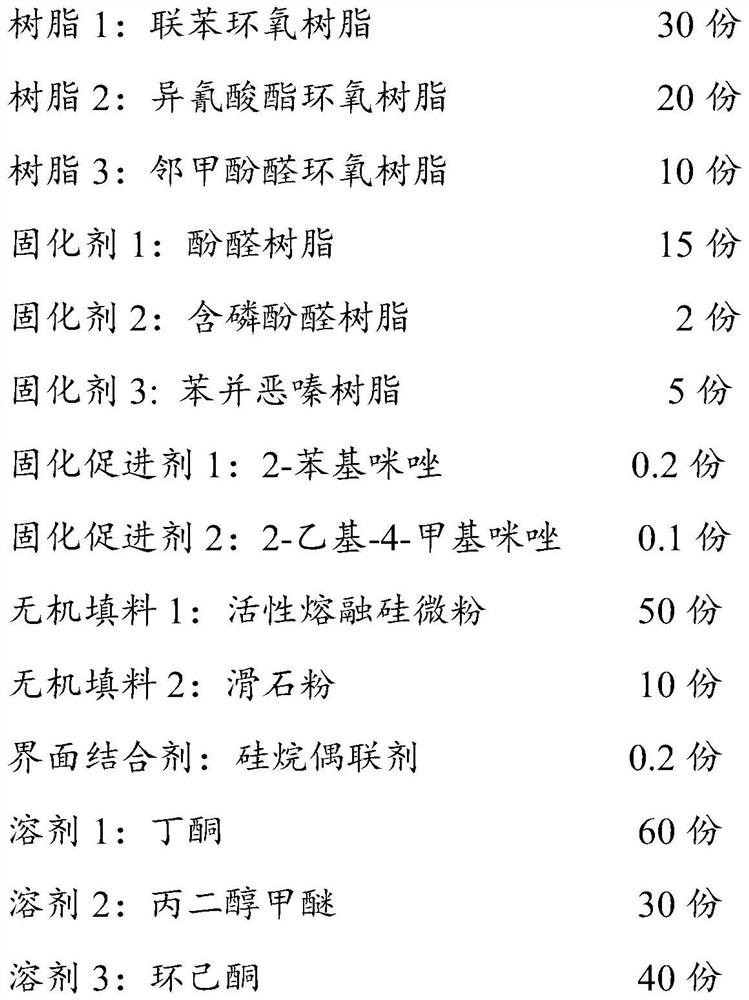

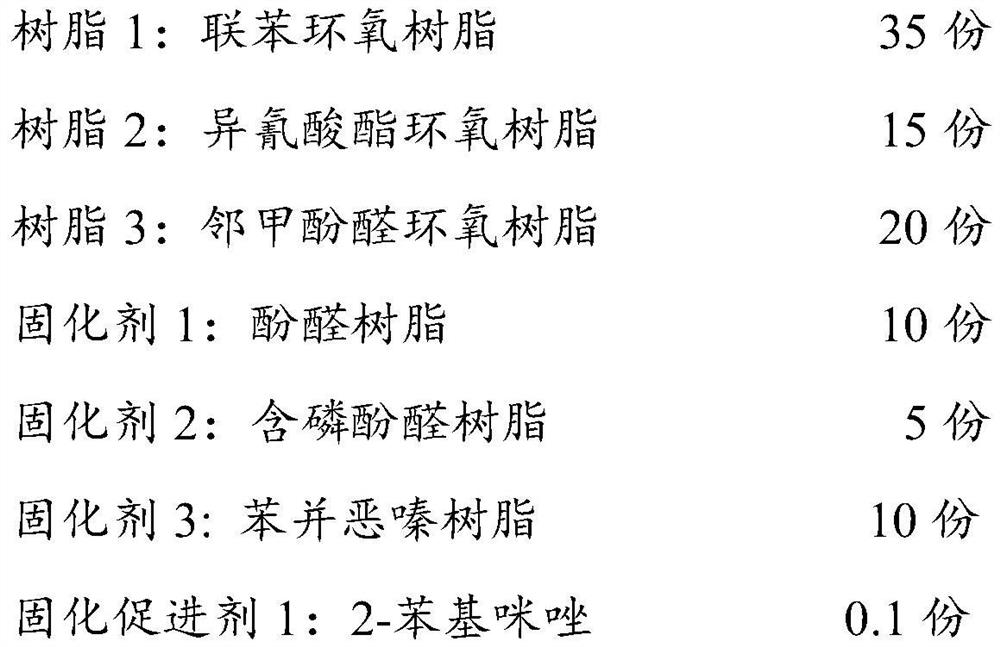

The invention provides a glue solution for halogen-free medium-Tg medium-loss copper-clad plate as well as preparation method and application of the glue solution. The glue solution is prepared from the following components in parts by weight: 25-35 parts of biphenyl epoxy resin, 15-25 parts of isocyanate epoxy resin, 10-30 parts of o-cresol formaldehyde epoxy resin, 10-20 parts of phenolic resin,1-5 parts of phosphorus-containing phenolic resin, 5-15 parts of benzoxazine resin, 0.2-0.5 part of curing accelerator, 50-70 parts of inorganic filler, 0.1-0.3 part of an interface bonding agent, and 120-150 parts of a solvent. A halogen-free medium-Tg medium-loss copper-clad plate prepared from the glue solution has the advantages of favorable flame retardancy, favorable heat resistance, low water absorptivity and excellent dielectric properties.

Owner:林州致远电子科技有限公司

Liquid development photoimageable ink and preparation method thereof

InactiveCN108530988AImprove brittlenessShort curing timeInksPhotosensitive materials for photomechanical apparatusFlexible circuitsSilicon dioxide

The invention discloses liquid development photoimageable ink and a preparation method thereof. The liquid development photoimageable ink comprises, by weight, 25-35 parts of multi-element anhydride modified linear phenolic epoxy acrylate, 10-15 parts of alkali-developable photosensitive resin, 10-20 parts of acrylic acid active monomer, 5-10 parts of photoinitiator, 5-15 parts of silicon dioxide,2-6 parts of fluorine-containing surfactant, 1-3 parts of defoaming agent, 1-3 parts of water reducing agent and 1-3 parts of leveling agent. The liquid development photoimageable ink and the preparation method thereof have the advantages that multi-element phthalic anhydride is used to modify o-cresol formaldehyde epoxy acrylate to obtain the multi-element anhydride modified linear phenolic epoxy acrylate, the multi-element anhydride modified linear phenolic epoxy acrylate combines with the alkali-developable photosensitive resin and the acrylic acid active monomer to prepare the liquid development photoimageable ink through the mutual coordination and promotion of the molecular structures of the three, the prepared liquid development photoimageable ink is short in curing time, good in compatibility, high in printing precision and applicable to flexible circuit board printing, and the problem that a cured film is high in brittleness is improved evidently.

Owner:江苏海田电子材料有限公司

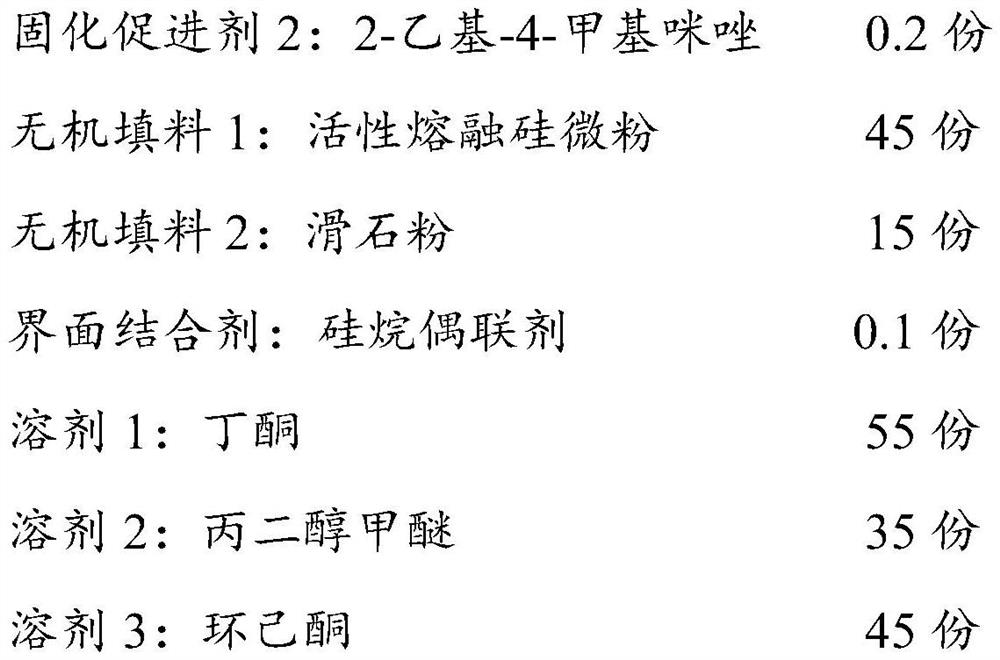

Anti-corrosion powder coating for deep well pipeline as well as preparation method and application of anti-corrosion powder coating

ActiveCN114539871AHigh glass transition temperatureImprove high temperature resistanceProductsReagentsPolymer scienceFirming agent

The invention provides a deep well pipeline anti-corrosion powder coating as well as a preparation method and application thereof. The anticorrosive powder coating for the deep well pipeline comprises the following components in parts by weight: 48-54 parts of epoxy resin, 12-13.5 parts of a curing agent, 2-4 parts of modified graphene, 1-2 parts of an auxiliary agent and 26.5-37 parts of pigment filler, wherein the epoxy resin comprises bisphenol A linear novolac epoxy resin, o-cresol formaldehyde epoxy resin and bisphenol A epoxy resin; the curing agent comprises a phenolic hydroxyl curing agent and an aromatic amine curing agent. According to the anticorrosive powder coating for the deep well pipeline, the crosslinking density and the rigid group content can be increased, so that the glass transition temperature of the powder coating is increased, the high-temperature resistance and the hardness of the coating are enhanced, the coating can bear high-temperature and low-temperature alternation, and the coating can meet the use requirement of a high-pressure condition; and the protection requirement of the deep well oil pipe can be better met.

Owner:FUJIAN WANAN IND +1

Plastic composition for encapsulation and its application

InactiveCN109111689BLow viscositySmall expansion coefficientSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceFirming agent

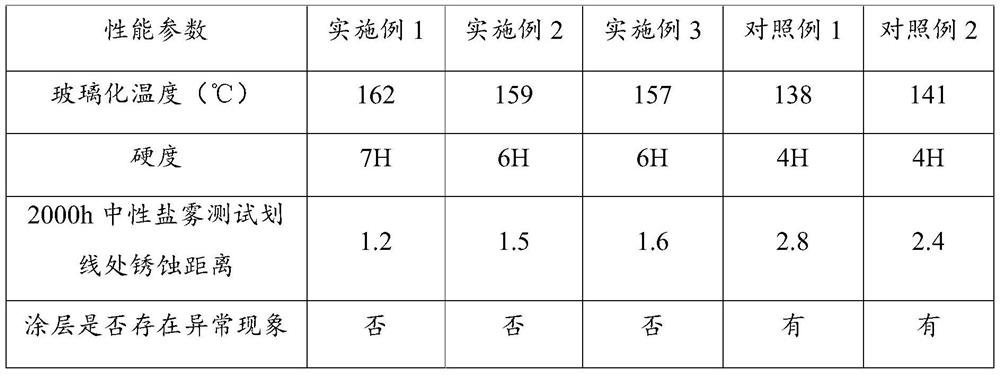

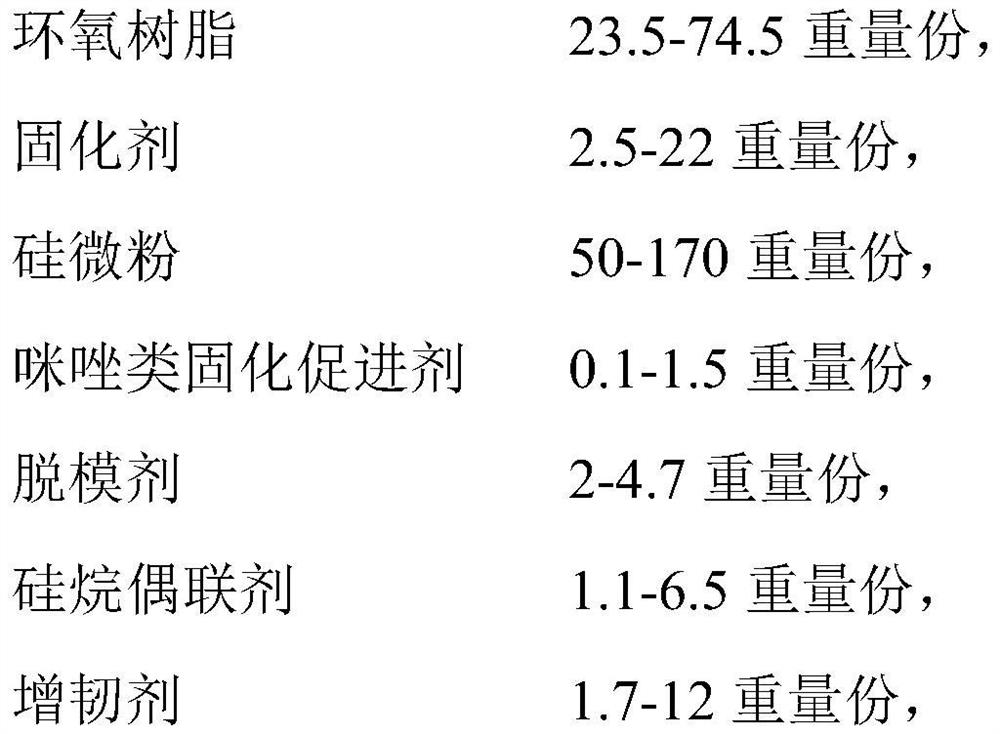

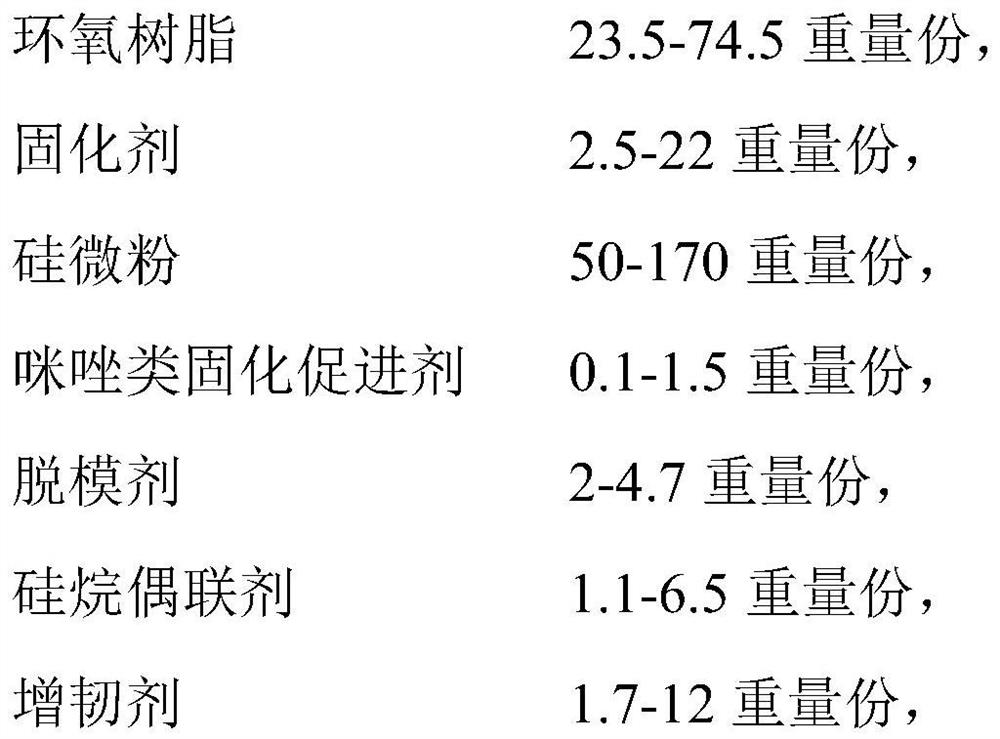

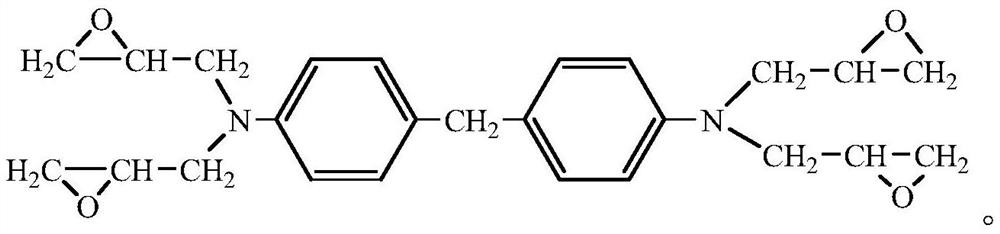

The present invention relates to the field of packaging materials, and discloses a plastic composition for packaging and an application thereof. The plastic composition contains epoxy resin having specific type and proportion, a curing agent, silicon micropowder, an imidazole curing accelerator, a mold release agent, a silane coupling agent, and a toughening agent, wherein, the epoxy resin comprises liquid crystal epoxy resin, glycidyl amine epoxy resin, o-cresol formaldehyde epoxy resin and biphenyl epoxy resin, wherein the curing agent is melamine modified novolac phenolic resin. The invention also discloses an application of the composition in preparation of the plastic used for package of an integrated circuit. Through cooperation usage of the specific epoxy resin, the curing agent, the filler, the auxiliary agent and the like, the plastic used for packaging with better performance is obtained, can be used for packaging the large-scale integrated circuit, and has advantage of environmental protection.

Owner:MIDEA SMART TECH CO LTD +1

Halogen-free resin composition with low expansion coefficient, laminated board and printed circuit board

PendingCN114806078AImprove toughnessImprove heat resistanceGlass/slag layered productsCoatingsPolymer scienceFire retardant

The invention discloses a low-expansion-coefficient halogen-free resin composition, a laminated board and a printed circuit board. The halogen-free resin composition provided by the invention comprises the following components in parts by weight: (a) 30 to 40 parts of o-cresol formaldehyde epoxy resin, (b) 50 to 70 parts of bismaleimide resin, (c) 75 to 105 parts of cyanate hardener, (d) 30 to 45 parts of bisphenol A type DOPO hardener, (e) 10 to 20 parts of non-DOPO phosphorus-containing flame retardant and (f) 2 to 12 parts of DOPO flame retardant. According to the halogen-free resin composition provided by the invention, through specific components and proportions, the epoxy resin composition with low expansion coefficient, low dielectric loss and high rigidity can be provided, and better toughness and heat resistance are provided.

Owner:ITEQ WUXIELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com