High-temperature-resistant epoxy adhesive tape and preparation method thereof

An epoxy tape, high temperature resistant technology, applied in epoxy resin glue, novolac epoxy resin adhesive, adhesive and other directions, can solve the problems of complex production process, insufficient strength, and failure to reach heat resistance temperature, etc. To achieve the effect of increasing polar groups, improving strength and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take Example 1 as an example:

[0033] S1: Dissolve o-cresol novolac epoxy resin (CNE202) in ethyl acetate, add carboxylated acrylic resin, mix well, add high-functional epoxy resin, bisphenol A epoxy resin and γ-(2,3- Glycidoxy)propyltrimethoxysilane (KH-560), mix well, finally add dicyandiamide (DDA) and 4,4,-diphenylsulfonediamine (DDS), mix well, add filler, Mix evenly, that is the mixed glue;

[0034] S2: After filtering the mixed glue, apply the mixed glue on the side of the release film within 5 minutes at 110°C, and dry it to form a high-temperature resistant epoxy film on the side of the release film. The thickness of the adhesive film is 20 μm, and the other side of the high-temperature-resistant epoxy adhesive film is covered with a release film, and cut to obtain the high-temperature-resistant epoxy adhesive tape.

Embodiment 1- Embodiment 8

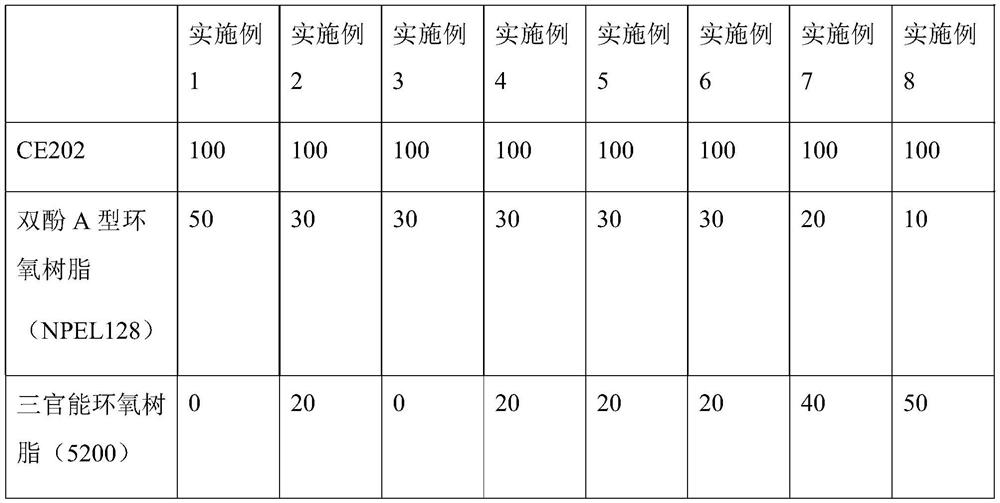

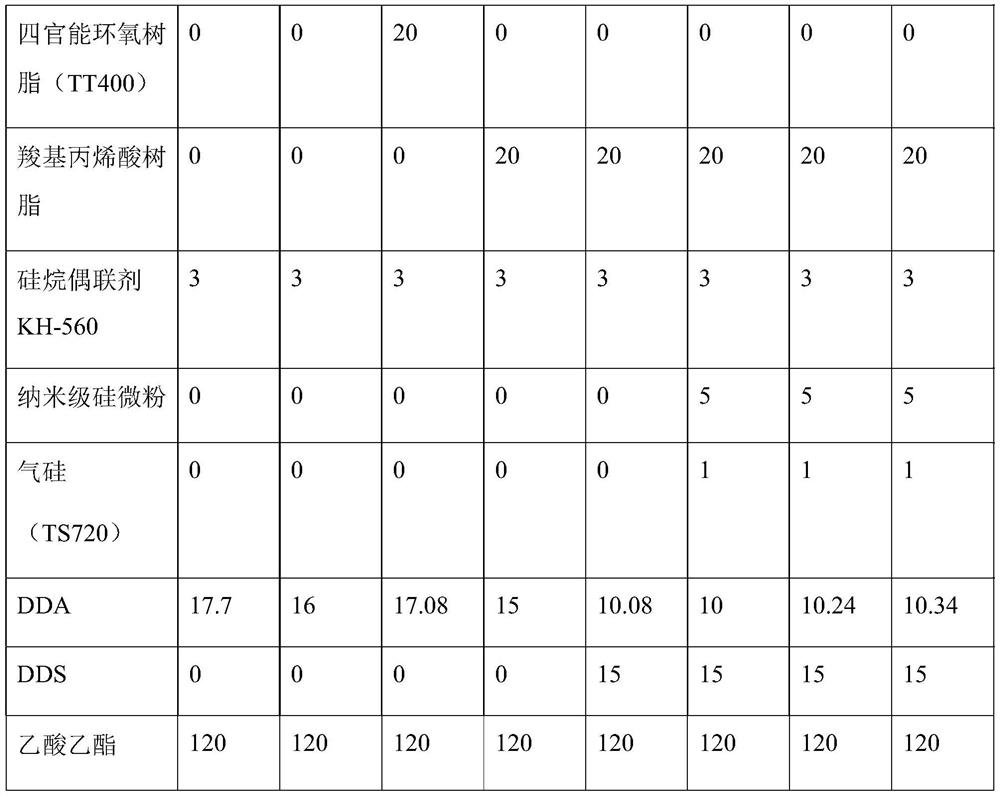

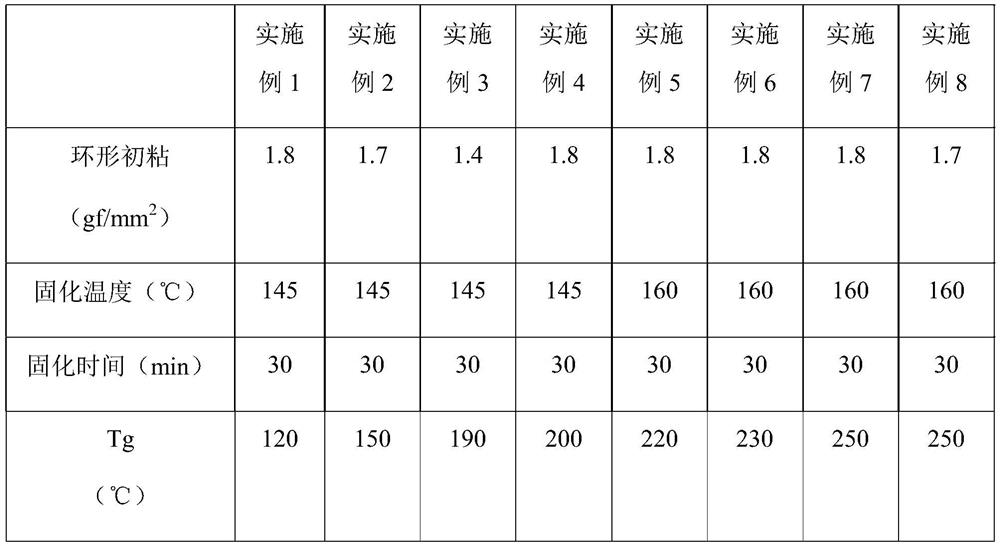

[0035] Embodiment 1-Example 8: According to the replacement of conditions such as compounds and content in Example 1, see Table 1 for specific content data.

[0036] Table 1 Example 1-Example 8 High temperature resistant epoxy tape

[0037]

[0038]

Embodiment 9

[0039] Embodiment 9: comprise the following steps:

[0040] S1: Nitrogen gas was introduced, and under vacuum conditions, 1 part of polytetrahydrofuran, 1 part of ω-bishydroxyl-terminated polydimethylsiloxane, 1 part of polytetrahydrofuran, 1 part of dibutyltin dilaurate, 1 part of dehydrated Mix one part of N,N-dimethylformamide and 20 parts of ethylene glycol evenly, add 10 parts of 4-4'-diphenylmethane diisocyanate, react at 70-80°C for 2 hours, then add 10 parts of 4-4 '-diphenylmethane diisocyanate for chain extension reaction, add 20 parts of methanol, react for 2h, which is modified polyurethane;

[0041] S2: After ultrasonically reacting 5 parts of carboxylated carbon nanotubes with 10 parts of dimethylformamide for 1 h, add 0.1 parts of γ-aminopropyltriethoxysilane and 3 parts of N-N'dicyclohexylcarbodiimide Mix evenly, pass in nitrogen, heat up to 40°C, react for 3 hours, wash with water, filter and dry, mix with 5 parts of ethanol and 5 parts of water, after ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com