Anti-corrosion powder coating for deep well pipeline as well as preparation method and application of anti-corrosion powder coating

A powder coating and pipeline technology, applied in the field of deep well pipeline anti-corrosion powder coating and its preparation, can solve the problems of high heat resistance and difficult to meet the requirements, achieve the improvement of crosslinking density and rigid group content, meet protection requirements, improve glass effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

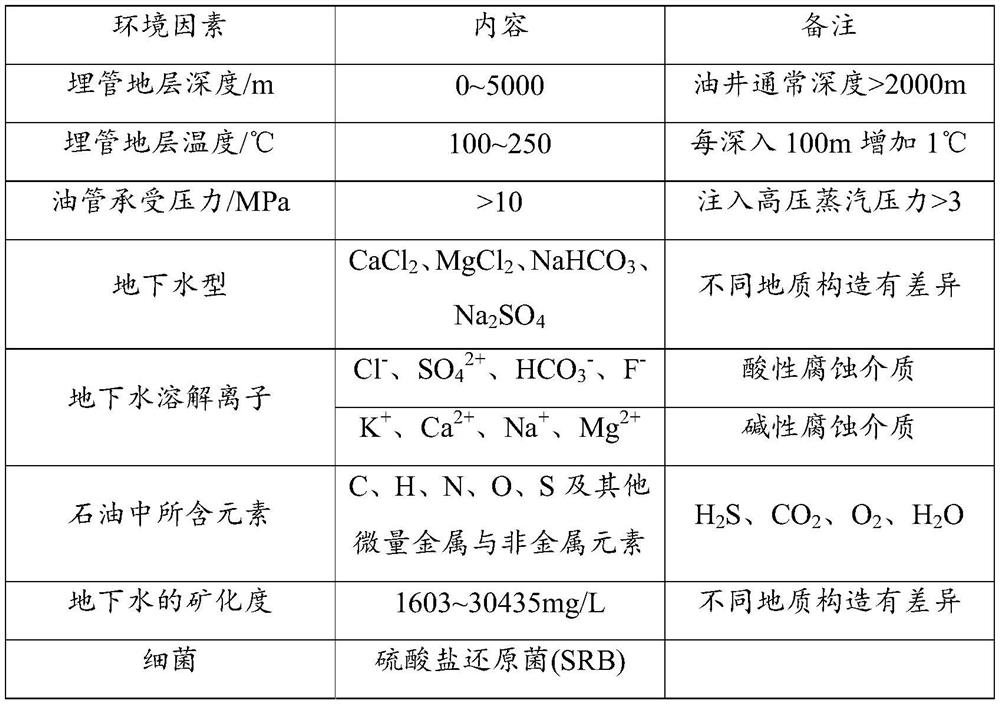

Problems solved by technology

Method used

Image

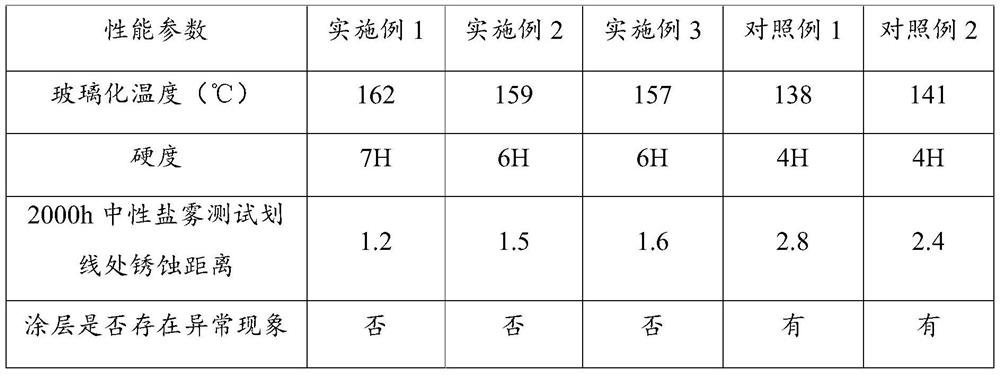

Examples

Embodiment 1

[0028] The preparation method of the deep well pipeline anti-corrosion powder coating of the present embodiment, the steps are as follows:

[0029] S1: Preparation of modified graphene

[0030] 10g of silane coupling agent was dissolved in 5L of alcohol-water mixed solvent (water / ethanol volume ratio=25:75) and fully stirred to obtain a silane coupling agent solution; 20g of graphene was put into the above-mentioned silane coupling agent solution, After ultrasonic dispersion for 1 hour, heated to 70 °C, stirred and refluxed for 8 hours, filtered and washed with an alcohol-water mixed solvent to remove excess silane coupling agent to obtain silane-modified modified graphene.

[0031] S2: Preparing the premix

[0032] Weigh 150g of bisphenol A novolac epoxy resin, 150g of o-cresol novolac epoxy resin, 200g of bisphenol A epoxy resin, 100g of phenolic hydroxyl curing agent, and 25g of aromatic amine curing agent, put them into a mixer and stir for 1 min. The molar ratio of the ...

Embodiment 2

[0036] The preparation method of the deep well pipeline anti-corrosion powder coating of the present embodiment, the steps are as follows:

[0037] S1: Preparation of modified graphene

[0038] 10g of silane coupling agent was dissolved in 5L of alcohol-water mixed solvent (water / ethanol volume ratio=20:80) and fully stirred to obtain a silane coupling agent solution; 18g of graphene was put into the above-mentioned silane coupling agent solution, After ultrasonic dispersion for 1 hour, heated to 60° C., stirred and refluxed for 9 hours, filtered and washed with an alcohol-water mixed solvent to remove excess silane coupling agent to obtain silane-modified modified graphene.

[0039] S2: Preparing the premix

[0040] Weigh 150g of bisphenol A novolac epoxy resin, 150g of o-cresol novolac epoxy resin, 180g of bisphenol A epoxy resin, 100g of phenolic hydroxyl curing agent, and 30g of aromatic amine curing agent, put them into a mixer and stir for 1 min; then add 30g modified ...

Embodiment 3

[0044] The preparation method of the deep well pipeline anti-corrosion powder coating of the present embodiment, the steps are as follows:

[0045] S1: Preparation of modified graphene

[0046] 10g of silane coupling agent was dissolved in 5L of alcohol-water mixed solvent (water / ethanol volume ratio=30:70) and fully stirred to obtain a silane coupling agent solution; 22g of graphene was put into the above-mentioned silane coupling agent solution, After ultrasonic dispersion for 1 hour, heated to 80 °C, stirred and refluxed for 7 hours, filtered and washed with an alcohol-water mixed solvent to remove excess silane coupling agent to obtain silane-modified modified graphene.

[0047] S2: Preparing the premix

[0048]Weigh 150g of bisphenol A novolac epoxy resin, 180g of o-cresol novolac epoxy resin, 210g of bisphenol A epoxy resin, 100g of phenolic hydroxyl curing agent, 20g of aromatic amine curing agent, put it into a mixer and stir for 1min; then add 40g modified graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com