A method for preparing a high specific capacity nanocomposite material by using a dual template

A nanocomposite material, high specific capacity technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of low specific capacitance of composites, complex process equipment, harsh reaction conditions, etc. , to achieve the effect of good rate characteristics and cycle stability, reliable preparation principle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

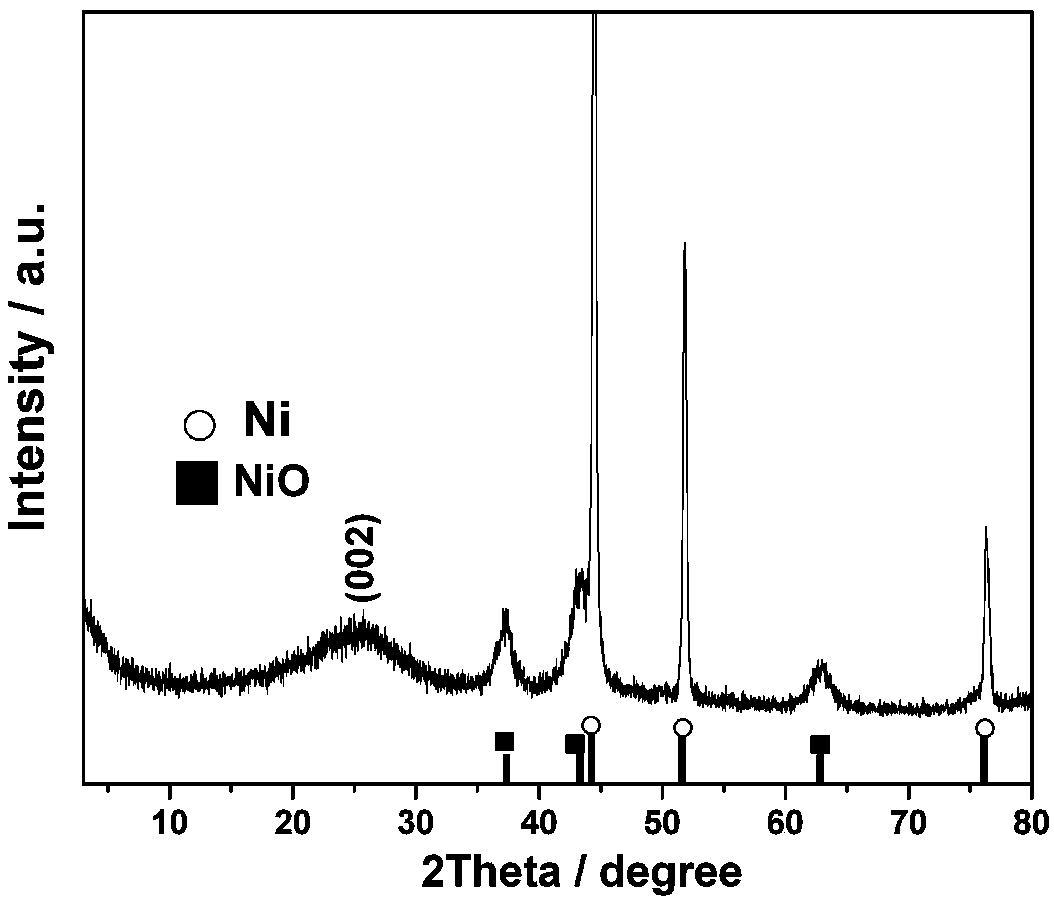

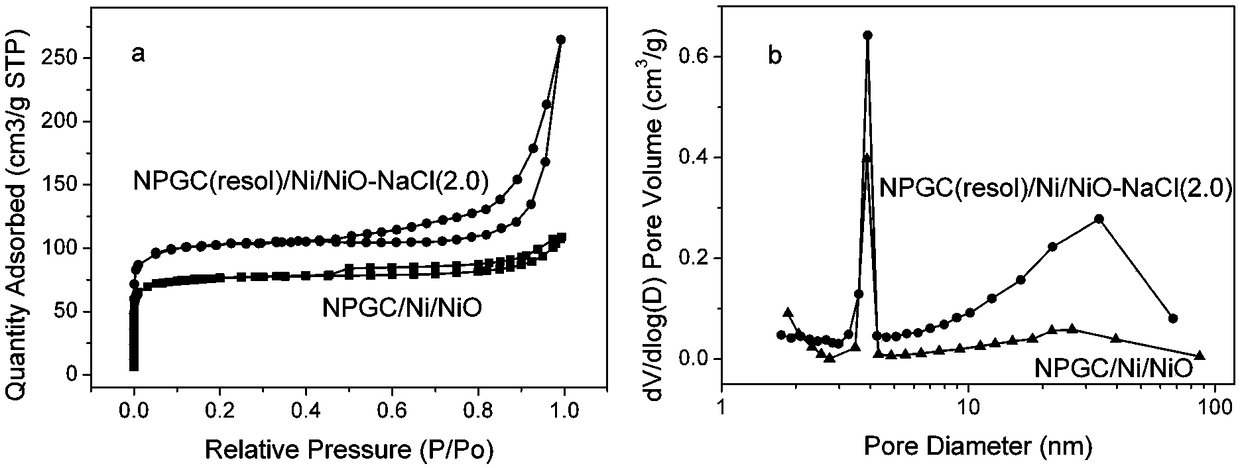

Embodiment 1

[0030] Take 30mL polyacrylamide mother liquor (5wt%), add 45mL deionized water and dilute to form a uniform solution with a concentration of 2%, add dropwise 10.0g F127-resole phenolic resin mixture aqueous solution (mass concentration is 6.84%) under stirring conditions, Stir well. Add 2.67g NiCl to the solution 2 ·6H 2 O, stir well, the nickel ion concentration in the solution is 150mmol / L; Add 2.49g NaCl in the solution, stir well, the sodium chloride concentration in the solution is 0.5mol / L; Finally, in the polymer solution, add dropwise 300 μ L hydrochloric acid ( 3mol / L) and stirred evenly, the above solution was transferred to a polytetrafluoroethylene-lined autoclave, and hydrothermally reacted at 130°C for 15h to obtain a cross-linked polyacrylamide / nickel chloride / sodium chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8 Pa) to obtain a cross-linked polyacrylamide / nickel ...

Embodiment 2

[0032] Take 30mL polyacrylamide mother liquor (5wt%), add 45mL deionized water and dilute to form a uniform solution with a concentration of 2%, add dropwise 10.0g F127-resole phenolic resin mixture aqueous solution (mass concentration is 6.84%) under stirring conditions, Stir well. Add 2.67g NiCl to the solution 2 ·6H 2 O, stir evenly, the nickel ion concentration in the solution is 150mmol / L; Add 4.98g NaCl in the solution, stir well, the sodium chloride concentration in the solution is 1.0mol / L; Finally, in the polymer solution, drip 300 μ L hydrochloric acid ( 3mol / L) and stirred evenly, the above solution was transferred to a polytetrafluoroethylene-lined autoclave, and hydrothermally reacted at 130°C for 15h to obtain a cross-linked polyacrylamide / nickel chloride / sodium chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8 Pa) to obtain a cross-linked polyacrylamide / nickel chlori...

Embodiment 3

[0034] Take 30mL polyacrylamide mother liquor (5wt%), add 45mL deionized water and dilute to form a uniform solution with a concentration of 2%, add dropwise 10.0g F127-resole phenolic resin mixture aqueous solution (mass concentration is 6.84%) under stirring conditions, Stir well. Add 2.67g NiCl to the solution 2 ·6H 2 O, stir evenly, the nickel ion concentration in the solution is 150mmol / L; Add 7.46g NaCl in the solution, stir well, the sodium chloride concentration in the solution is 1.5mol / L; Finally, in the polymer solution, add dropwise 300 μ L hydrochloric acid ( 3mol / L) and stirred evenly, the above solution was transferred to a polytetrafluoroethylene-lined autoclave, and hydrothermally reacted at 130°C for 15h to obtain a cross-linked polyacrylamide / nickel chloride / sodium chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8 Pa) to obtain a cross-linked polyacrylamide / nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com