Glue solution for halogen-free medium-Tg medium-loss copper-clad plate as well as preparation method and application of the glue solution

A technology of copper clad laminate and glue, which is applied in the field of halogen-free medium Tg medium loss copper clad laminate glue and its preparation, can solve the problems of low heat resistance, high cost, high brittleness, etc., achieve excellent flame retardancy, meet High transmission, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of glue

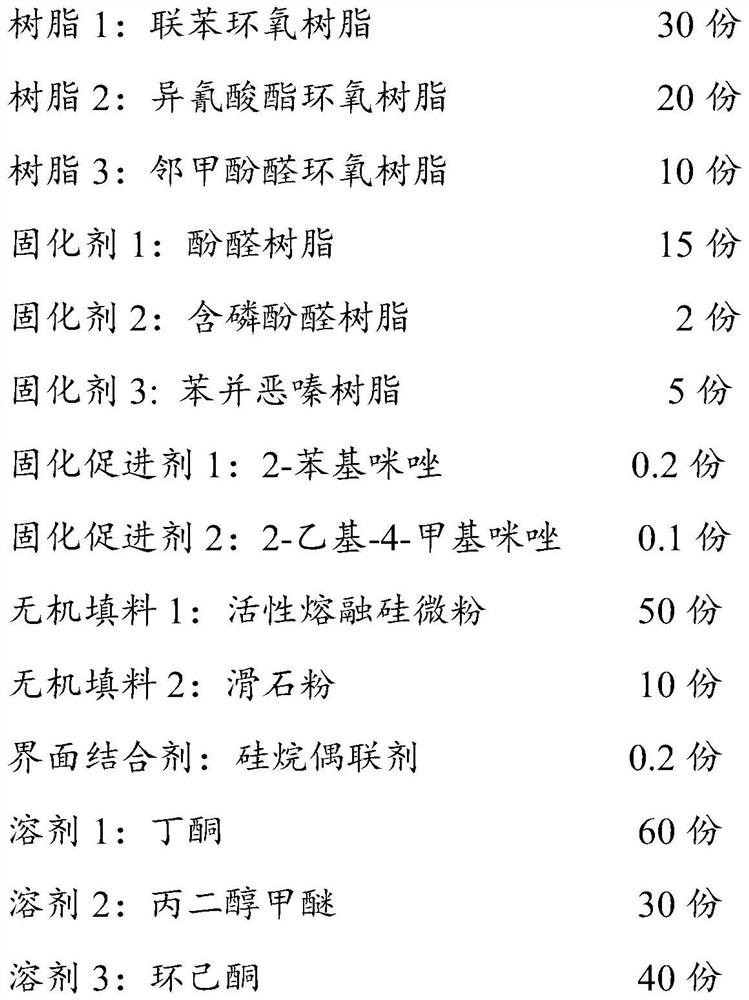

[0032] The glue solution of the present embodiment is made up of the component of following parts by weight:

[0033]

[0034] The preparation steps of glue solution are as follows:

[0035] After cleaning the glue mixing tank with acetone, put in the above solvent 1, solvent 2 and interface binder according to the weight part, after adding the curing agent, stir at 1500r / min for 2 hours to completely dissolve the curing agent, and then add the remaining components in sequence , Stir at a speed of 1000r / min for 3h, then stir at a speed of 500r / min for 2h, after the gelation time of the glue is tested, the glue is prepared.

[0036] 2. Preparation of prepreg

[0037] The glue solution prepared above was made into a prepreg in a conventional manner; wherein, the controlled glue content was 42%, the fluidity was 38%, the gelation time was 150s, and the volatile matter was <0.5%.

[0038] 3. Preparation of Halogen-free Medium Tg Medium Loss Co...

Embodiment 2

[0048] 1. Preparation of glue

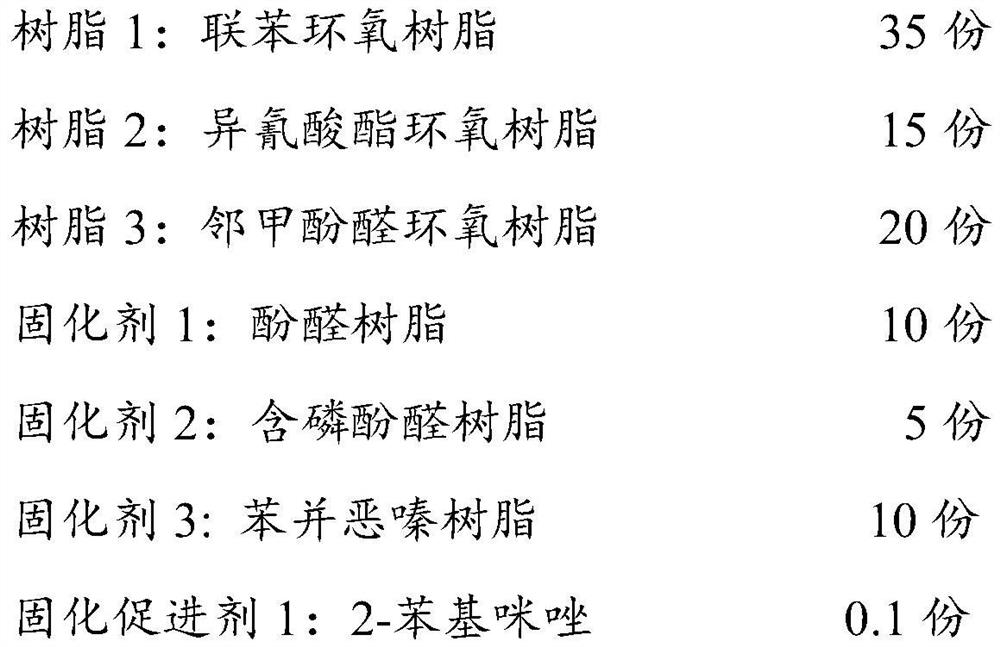

[0049] The glue solution of the present embodiment is made up of the component of following parts by weight:

[0050]

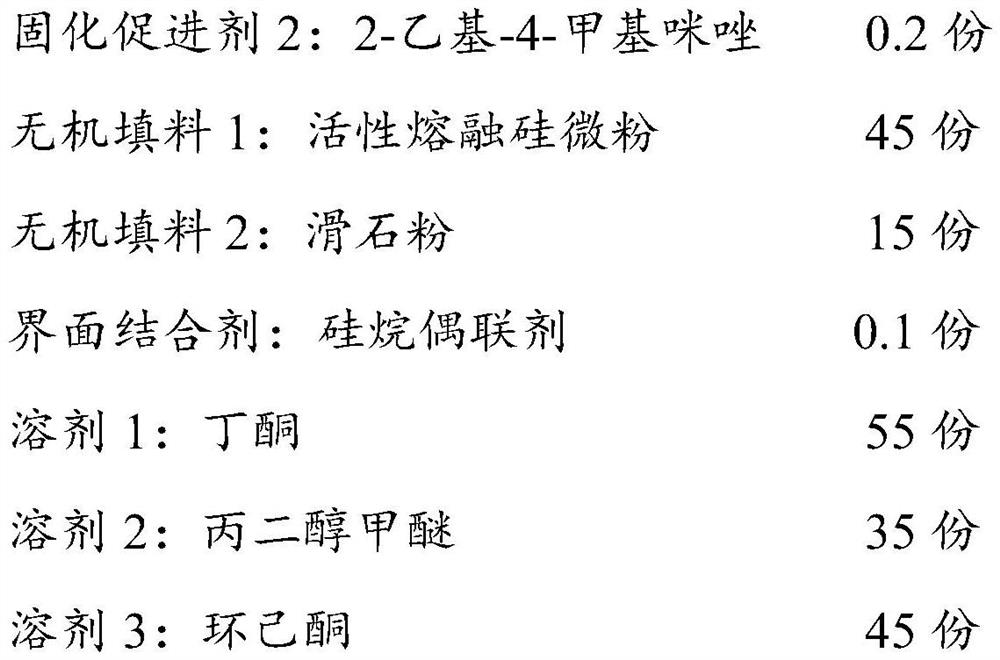

[0051]

[0052] The preparation steps of glue solution are as follows:

[0053] After cleaning the glue mixing tank with acetone, put in the above solvent 1, solvent 2 and interface binder according to the weight part, after adding the curing agent, stir at 1500r / min for 2 hours to completely dissolve the curing agent, and then add the remaining components in sequence First, stir at a speed of 1200r / min for 2h, then stir at a speed of 600r / min for 1h, and after the gelation time of the glue is tested, the glue is prepared.

[0054] 2. Preparation of prepreg

[0055] The glue solution prepared above is made into a prepreg in a conventional manner; wherein, the glue content is controlled to be 40%, the fluidity is 40%, the gelation time is 120s, and the volatile matter is <0.5%.

[0056] 3. Preparation of Halogen-free Medi...

Embodiment 3

[0060] 1. Preparation of glue

[0061] The glue solution of the present embodiment is made up of the component of following parts by weight:

[0062]

[0063]

[0064] The preparation steps of glue solution are as follows:

[0065] After cleaning the glue mixing tank with acetone, put in the above solvent 1, solvent 2 and interface binder according to the weight part, after adding the curing agent, stir at 1500r / min for 2 hours to completely dissolve the curing agent, and then add the remaining components in sequence , Stir at a speed of 800r / min for 4 hours, and then stir for 3 hours at a speed of 400r / min. After the gelation time of the glue is tested, the glue is prepared.

[0066] 2. Preparation of prepreg

[0067] The glue solution prepared above was made into a prepreg in a conventional manner; wherein, the glue content was controlled to be 50%, the fluidity was 30%, the gelation time was 180s, and the volatile matter was <0.5%.

[0068] 3. Preparation of Haloge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com