Expansive anti-crack fiber concrete and preparation method thereof

A technology of anti-crack fiber and concrete, applied in the direction of fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problems that concrete cannot have repair ability, long time, etc., to shorten the healing time, the preparation method is simple, and the brittleness is large. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

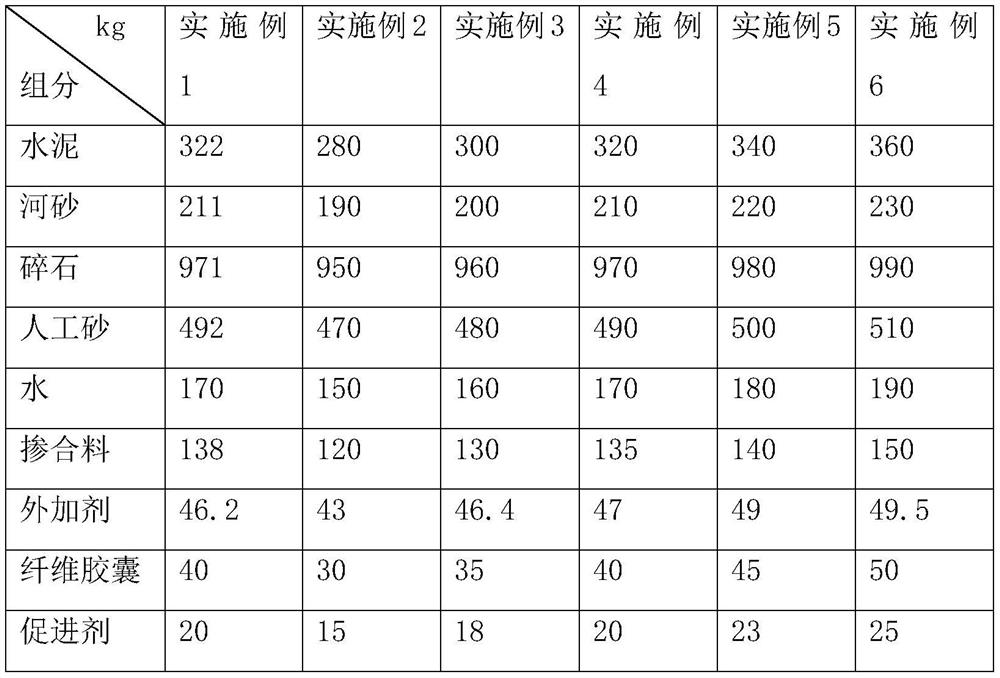

Examples

preparation example 1-10

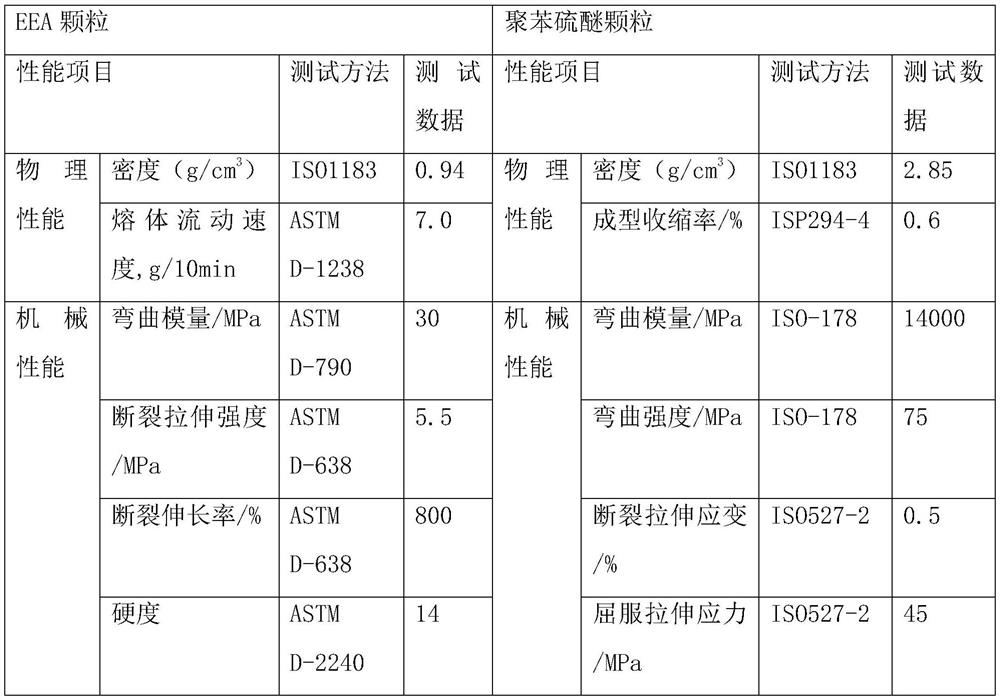

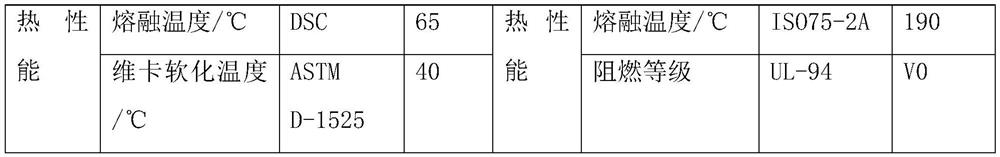

[0038] In Preparation Example 1-10, o-cresol novolac epoxy resin was selected from Changsha Fudakang Chemical Materials Co., Ltd., the model was CYDCN-200; the α-cyanoacrylate adhesive was selected from Shanghai Hezhiqin Intelligent Technology Co., Ltd., and the model was HZ701; Epoxy resin adhesive is selected from Jinan Yisheng Resin Co., Ltd., the model is E-128; polyphenylene sulfide fiber is selected from Tai’an Jiacheng Fiber Co., Ltd., the product number is T436; sorbitan monostearate, octyl The base phenol polyoxyethylene ether is selected from Jiangsu Maoheng Chemical Co., Ltd., the model is OP-40; the EEA particles are selected from the plastic raw material management department of Jinyunlai, Zhangmutou, Dongguan City, and the brand is 4700; the polyphenylene sulfide particles are selected from Shanghai Plastic Hair Plastic Co., Ltd., the model is P2020A; methyl methacrylate is selected from Jinan Huasheng Chemical Co., Ltd., the model is 2-2.

preparation example 1

[0039] Preparation Example 1: Dissolve 2kg o-cresol novolac epoxy resin with dimethylformamide solution, add 0.5kgα-cyanoacrylate adhesive, 0.25kg epoxy resin adhesive and 1kg polyphenylene sulfide fiber to o-cresol novolac epoxy resin Add an emulsifier to the resin, ultrasonically disperse for 20 minutes, and spray dry to obtain fiber capsules. The spray pressure is 0.5 MPa, and the drying temperature is 160°C. The preparation of o-cresol novolac epoxy resin, dimethylformamide solution and emulsifier An example is 1:0.4:0.05, and the emulsifier is made by mixing octylphenol polyoxyethylene ether and sorbitan monostearate in a mass ratio of 1:0.5.

preparation example 2

[0040] Preparation example 2: Dissolve 2.5kg o-cresol novolac epoxy resin with dimethylformamide solution, add 0.6kgα-cyanoacrylate adhesive, 0.28kg epoxy resin adhesive and 1.5kg polyphenylene sulfide fiber to o-cresol novolac Add an emulsifier to the epoxy resin, ultrasonically disperse for 25 minutes, and spray dry to obtain fiber capsules. The spray pressure is 1MPa, and the drying temperature is 150°C. The preparation example is 1:0.5:0.07, and the emulsifier is made by mixing octylphenol polyoxyethylene ether and sorbitan monostearate in a mass ratio of 1:0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com