High-resolution solder resist ink

A solder resist ink and high-resolution technology, which is applied in the field of solder resist ink, can solve the problems of lower resolution, low refractive index of photoresist, and low refractive index of solder resist ink, so as to improve resolution, increase refractive index, reduce photosensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

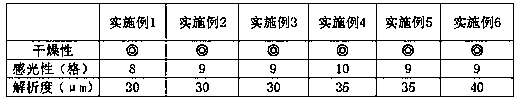

Examples

Embodiment 1

[0022] A high-resolution solder mask ink, which is prepared by mixing and stirring the components in the following mass ratios:

[0023] 27 parts of o-cresol epoxy acrylate resin, 25 parts of high refractive index inorganic filler, 8 parts of high refractive index light curing monomer, 2-methyl-1-(4-methylthiophenyl)-2-morpholine -1-acetone photoinitiator 3 parts, 2-isopropylthioxanthone photoinitiator 2 parts, amine curing agent 1 part, epoxy resin 10 parts, 6 parts triglycidyl isocyanurate, 15 parts solvent , 1 part of defoaming agent, 1 part of leveling agent and 1 part of pigment;

[0024] Among them, the high refractive index inorganic filler is rutile with a refractive index of 2.71; the high refractive index light-curing monomer is biphenylmethanol acrylate with a refractive index of 1.60; the amine curing agent is dicyandiamine; the epoxy resin is BPF Type epoxy resin; solvent is dipropylene glycol monomethyl ether; defoamer is Shin-Etsu KS-66 from Shin-Etsu Chemical Co., ...

Embodiment 2

[0026] A high-resolution solder mask ink, which is prepared by mixing and stirring the components in the following mass ratios:

[0027] 45 parts of o-cresol epoxy acrylate resin, 26.5 parts of high refractive index inorganic filler, 5 parts of high refractive index light-curing monomer, 2-methyl-1-(4-methylthiophenyl)-2-morpholine 1.5 parts of -1-acetone photoinitiator, 0.5 parts of 2-isopropylthioxanthone photoinitiator, 0.5 parts of amine curing agent, 5 parts of epoxy resin, 4 parts of triglycidyl isocyanurate, 10 parts of solvent , 1 part of defoaming agent, 0.5 part of leveling agent and 0.5 part of pigment;

[0028] Among them, the high refractive index inorganic filler is anatase, which has a refractive index of 2.55; the high refractive index light-curing monomer is 9,9-bis[4-(2-acryloxyethoxy)phenyl] fluorene bisphenol fluorene It is a diacrylate with a refractive index of 1.61; amine curing agent is melamine; epoxy resin is BPF type epoxy resin; solvent is dipropylene g...

Embodiment 3

[0030] A high-resolution solder mask ink, which is prepared by mixing and stirring the components in the following mass ratios:

[0031] 35 parts of o-cresol epoxy acrylate resin, 30 parts of high refractive index inorganic filler, 6 parts of high refractive index light curing monomer, 2-methyl-1-(4-methylthiophenyl)-2-morpholine -1-acetone photoinitiator 2.25 parts, 2-isopropylthioxanthone photoinitiator 0.75 parts, amine curing agent 1 part, epoxy resin 6 parts, 5 parts triglycidyl isocyanurate, 12 parts solvent , 1 part of defoaming agent, 0.5 part of leveling agent and 0.5 part of pigment;

[0032] Among them, the high refractive index inorganic filler is anatase with a refractive index of 2.55; the high refractive index light-curing monomer is 9,9-bis[4-(2-acryloxyethoxy)phenyl] fluorene bisphenol fluorene It is a diacrylate with a refractive index of 1.61; amine curing agent is melamine; epoxy resin is BPF type epoxy resin; solvent is dipropylene glycol monomethyl ether; def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com