Plastic composition for encapsulation and its application

A technology of plastic composition and epoxy resin, applied in circuits, electric solid devices, semiconductor devices, etc., can solve the problems of poor performance, water absorption and heat resistance, and achieve high thermal conductivity, low viscosity and low expansion coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

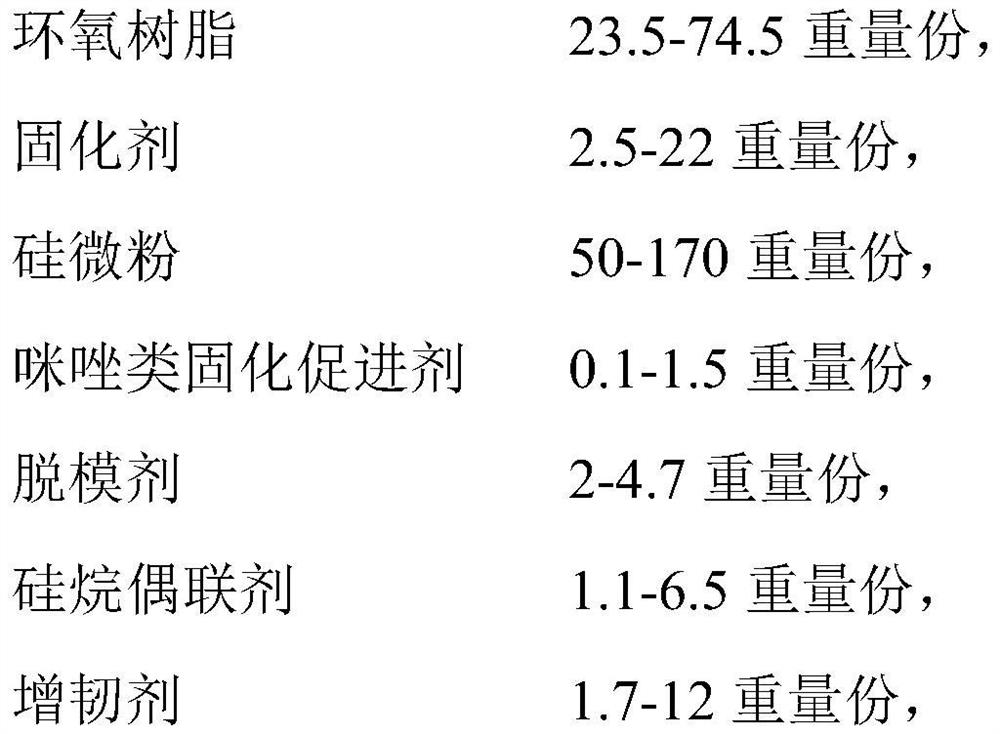

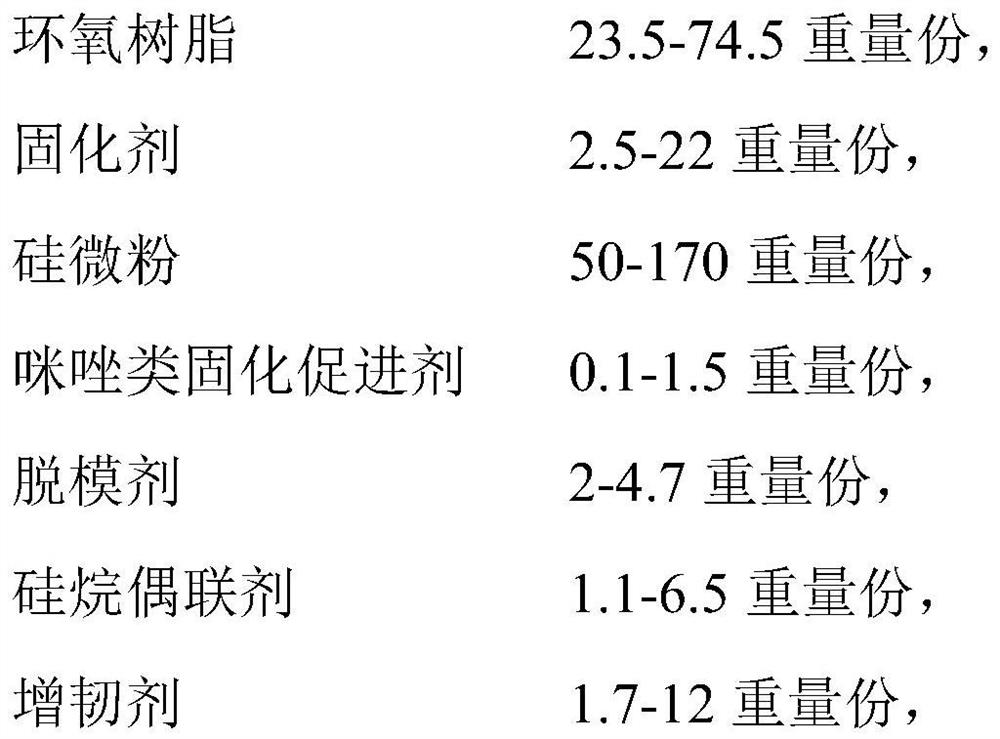

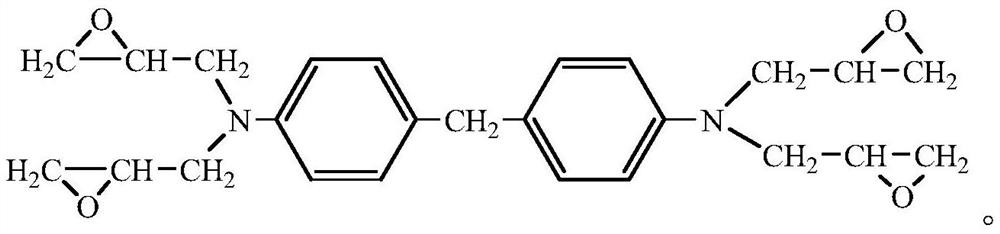

Method used

Image

Examples

Embodiment 1

[0056] The method for preparing plastics for encapsulation comprises: after accurately weighing the components (g) as shown in Table 1, the filler is treated with a silane coupling agent in a mixer, first mixed for 5 minutes, and then left to stand for 3 minutes, so Repeat 5 times for surface treatment; then add other components in proportion, use a metal detector to detect and remove metal impurities through magnetic separation, and then mix for 3 minutes to melt and knead the mixture. The kneading temperature is 100°C. The time is 4 minutes; after the product is cooled, it is pulverized and sieved (the undersize of a 100-mesh sieve is taken), transported in a pipeline, magnetically separated, stirred and mixed, ingoted and subjected to a performance test. The performance test method is as follows:

[0057] The thermal conductivity is detected by a thermal conductivity tester (Tianjin Inbell Technology Development Co., Ltd., imDRY3001-II);

[0058] Melt viscosity: measured b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com