Water-based epoxy coating capable of being subjected to curtain coating and dip coating and preparation method thereof

A water-based epoxy coating and dip coating technology, which is applied in the field of coatings, can solve problems such as uneven surface of the coating film, easy generation of bubbles and pinholes, and easy cracking, and achieve high cross-linking density, excellent thermal stability, and extended pot life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

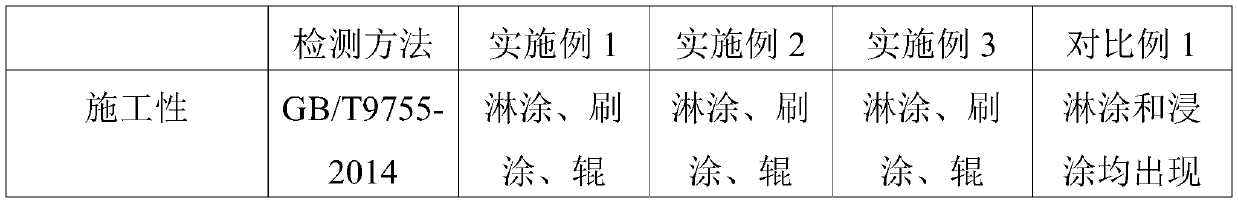

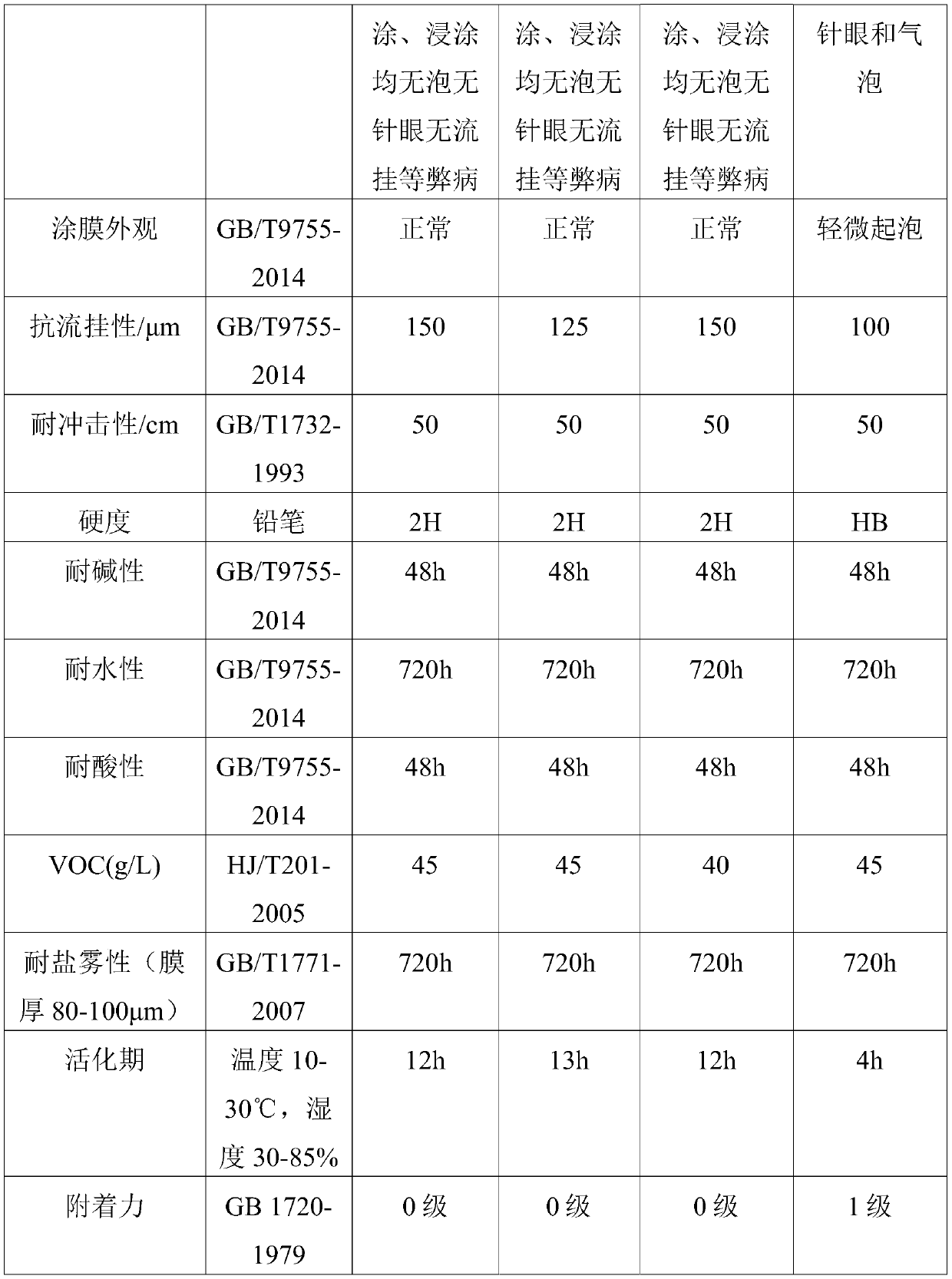

Examples

Embodiment 1

[0033] A water-based epoxy coating that can be sprayed and dipped, including A component and B component;

[0034] Described A component comprises the component of following mass percentage:

[0035] 22% bisphenol A type epoxy resin aqueous dispersion, 10% o-cresol novolac epoxy resin aqueous dispersion, 0.8% alcohol ester dodeca, 1.5% dispersing agent, 0.1% organomodified lithium montmorillonite Stone clay, 0.8% wetting and leveling agent, 0.4% thickener, 0.6% defoamer, 2% rutile titanium dioxide, 40% filler and 21.8% deionized water;

[0036] Described B component comprises the component of following mass percentage:

[0037] 45% water-based amine epoxy curing agent, 1% propylene glycol butyl ether and 54% deionized water;

[0038] The mass proportion of the A component and the B component is 5:1.

[0039]Wherein, bisphenol A type epoxy resin aqueous dispersion selects Hexion's Epikote 6520-WH-53A; o-cresol novolac epoxy resin aqueous dispersion selects Hexion's Epikote60...

Embodiment 2

[0046] A water-based epoxy coating that can be sprayed and dipped, including A component and B component;

[0047] Described A component comprises the component of following mass percentage:

[0048] 24% bisphenol-A type epoxy resin aqueous dispersion, 9% o-cresol novolac epoxy resin aqueous dispersion, 0.9% alcohol ester dodeca, 1.6% dispersant, 0.2% organomodified lithium montmorillonite Stone clay, 0.9% wetting and leveling agent, 0.5% thickener, 0.7% defoamer, 10% rutile titanium dioxide, 30% filler and 22.2% deionized water;

[0049] Described B component comprises the component of following mass percentage:

[0050] 50% water-based amine epoxy curing agent, 2% propylene glycol butyl ether and 48% deionized water;

[0051] The mass proportion of the A component and the B component is 6:1.

[0052] Wherein, bisphenol A type epoxy resin aqueous dispersion selects Hexion's Epikote 6520-WH-53A; o-cresol novolac epoxy resin aqueous dispersion selects Hexion's Epikote6006-W-...

Embodiment 3

[0059] A water-based epoxy coating that can be sprayed and dipped, including A component and B component;

[0060] Described A component comprises the component of following mass percentage:

[0061] 25% aqueous dispersion of bisphenol-A epoxy resin, 8% aqueous dispersion of o-cresol novolac epoxy resin, 1% alcohol ester dodeca, 1.8% dispersant, 0.2% organically modified lithium montmorillonite Stone clay, 1% wetting and leveling agent, 0.6% thickener, 0.7% defoamer, 20% rutile titanium dioxide, 20% filler and the balance deionized water;

[0062] Described B component comprises the component of following mass percentage:

[0063] 55% water-based amine epoxy curing agent, 3% propylene glycol butyl ether and 42% deionized water;

[0064] The mass proportion of the A component and the B component is 7:1.

[0065] Wherein, bisphenol A type epoxy resin aqueous dispersion selects Hexion's Epikote 6520-WH-53A; o-cresol novolac epoxy resin aqueous dispersion selects Hexion's Epiko...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com