Preparation method and construction method of low-viscosity thick-coating type solvent-free epoxy drinking water tank paint

A thick-coating, solvent-free technology, which is applied in the field of coating paints, can solve the problems of poor water quality, shortening the pot life, and high viscosity of the paint film, so as to reduce the phenomenon of easy moisture absorption and whitening, improve flexibility, adhesion, and moisturization. Good wet dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

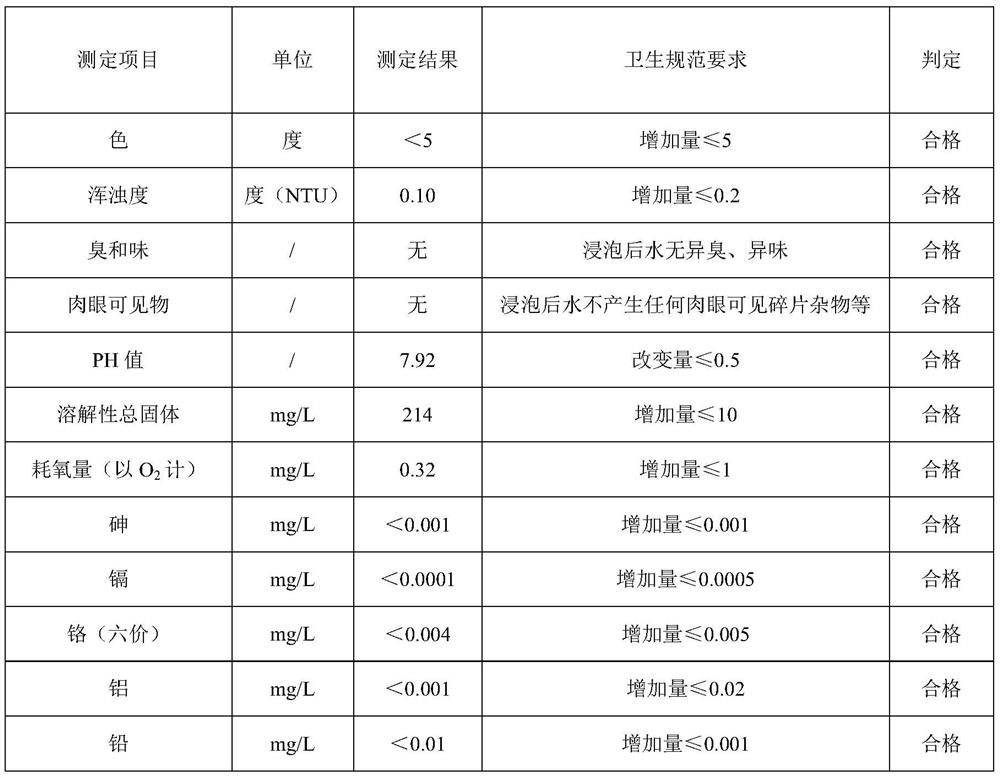

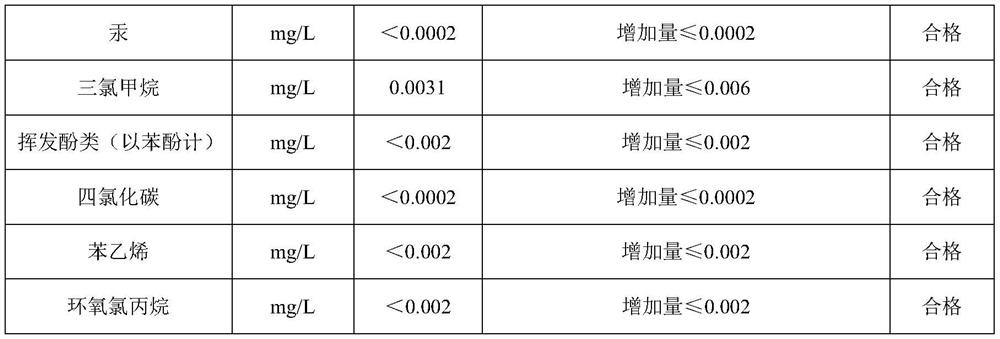

Examples

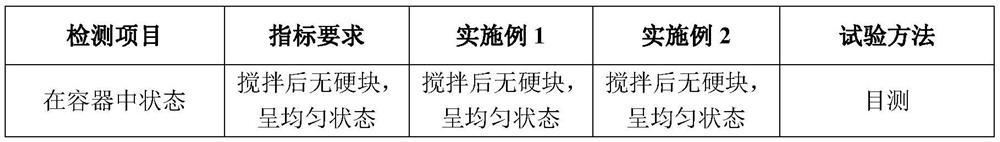

Embodiment 1

[0061] Low-viscosity thick-coat solvent-free epoxy drinking water tank paint, by mass percentage:

[0062] Liquid epoxy from bisphenol A: 21.6%;

[0063] Bisphenol F liquid epoxy resin 170: 8.4%;

[0064] Reactive diluent CGE: 3.8%;

[0065] Titanium dioxide: 5.8%;

[0066] Talc: 15.2%;

[0067] Feldspar powder: 21.5%;

[0069] Auxiliary: 5.2% - specifically composed of 1.0% thixotropic agent, 2.5% toughening agent, 0.6% wetting and dispersing agent, 0.1% defoaming agent, 0.2% leveling agent, 0.8% adhesion promoter;

[0070] Phenalkamine curing agent (Evonik Chemical's 2738): 16.7%.

[0071]First, bisphenol A liquid epoxy resin, bisphenol F liquid epoxy resin, reactive diluent CGE, and additives are uniformly dispersed, and then titanium dioxide, talc powder, feldspar powder and mica powder are added, and the high-power dispersion equipment is used for high-speed shear dispersion 45min, during which the temperature is guaranteed to be 45-65...

Embodiment 2

[0073] Low-viscosity thick coating type solvent-free epoxy drinking water tank paint, its component content is calculated as:

[0074] Bisphenol A liquid epoxy resin: 36.8%;

[0075] Reactive diluent CGE: 4%;

[0076] Titanium dioxide: 4.4%;

[0077] Quartz powder: 31.2%;

[0078] Auxiliary 3.6% - specifically composed of 0.9% thixotropic agent, 1.2% toughening agent, 0.5% wetting and dispersing agent, 0.1% defoaming agent, 0.2% leveling agent, 0.7% adhesion promoter;

[0079] Phenalkamine curing agent (NC-558 of Cartley Company): 20%.

[0080] First, bisphenol A liquid epoxy resin, reactive diluent CGE, and additives are uniformly dispersed, then titanium dioxide and quartz powder are added, and the high-power dispersion equipment is used for high-speed shear dispersion for 50 minutes. During this period, the temperature is guaranteed to be 45-65°C to obtain the base material , namely component A. Phenalkamine curing agent is component B. Make sure that the two componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com