Liquid development white photoimageable ink and preparation method thereof

A photosensitive solder resist ink, white technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

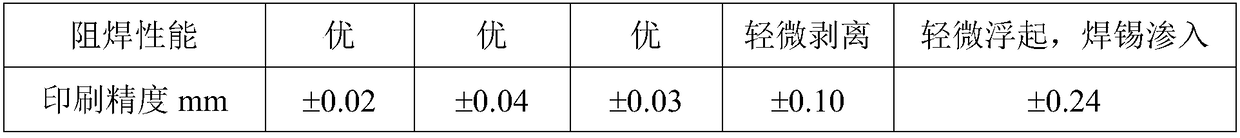

Image

Examples

Embodiment 1

[0036] Mix o-cresol novolac epoxy acrylate, butyl cellosolve, di-tert-butyl p-cresol polymerization inhibitor and triethylamine catalyst and heat up to 75° C. and stir for 45 minutes, then add the toluene solution of phthalic anhydride, (o The reaction molar ratio of cresol novolac epoxy acrylate, butyl cellosolve, di-tert-butyl p-cresol, triethylamine and phthalic anhydride is 3:1:0.2:0.3:2) to react until the acid value is the initial acid After half of the value, the solvent is distilled off under reduced pressure to obtain polybasic anhydride modified novolak epoxy acrylate.

Embodiment 2

[0038] Mix o-cresol novolak epoxy acrylate, butyl cellosolve, di-tert-butyl p-cresol polymerization inhibitor and triethylamine catalyst and heat up to 80° C. and stir for 30 minutes, then add the toluene solution of phthalic anhydride, (o The reaction molar ratio of cresol novolac epoxy acrylate, butyl cellosolve, di-tert-butyl p-cresol, triethylamine and phthalic anhydride is 3:1:0.2:0.3:5) to react until the acid value is the initial acid After half of the value, the solvent is distilled off under reduced pressure to obtain polybasic anhydride modified novolak epoxy acrylate.

Embodiment 3

[0040] Step 1: Take 42 parts of polybasic anhydride-modified novolak epoxy acrylate prepared in Example 1, 16 parts of acrylic active monomers (dipropylene glycol diacrylate and tetrahydrofuran acrylate monomers, the weight ratio is 1:1) and light 8 parts of the initiator 2-hydroxy-2-methyl-1-phenyl-1-acetone are put into the feeding channel;

[0041] Step 2: Use a high-speed disperser at a speed of 900r / min to disperse at 75°C for 0.6h, stop stirring and keep warm;

[0042] Step 3: Add 6 parts of titanium dioxide, 3 parts of barium sulfate, 4 parts of fluorine-containing surfactant, 2 parts of defoamer, 2 parts of water reducer and 2 parts of leveling agent into the feed liquid obtained in step 2, and continue with Stir at 600r / min for 0.4h;

[0043] Step 4: After stirring and mixing, use a hydraulic three-roller to grind until the particle size is below 300 nanometers;

[0044] Step 5: It is obtained after filtering with a 1 μm filter element filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com