Metal corrosion-resistant coating material for electrical equipment maintenance and preparation method of metal corrosion-resistant coating material

A corrosion-resistant technology for power equipment, applied in the field of metal corrosion-resistant coatings for power equipment maintenance and its preparation, can solve problems such as not being very effective, and achieve the effects of increasing adsorption capacity, uniform and dense film layer, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

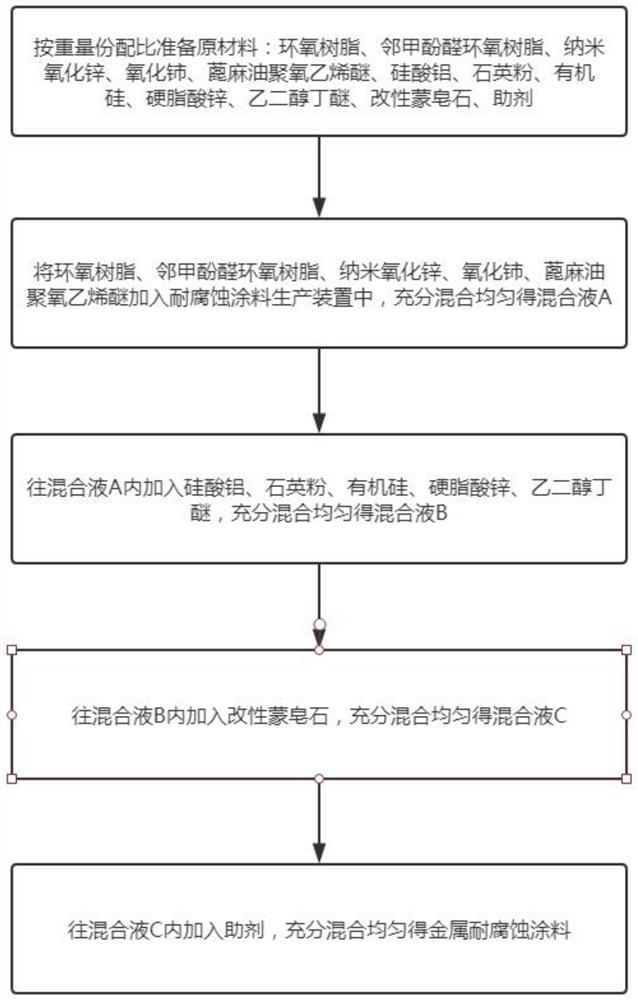

Method used

Image

Examples

Embodiment 1

[0044] A metal corrosion-resistant paint for maintenance of electrical equipment, comprising the following components in parts by weight:

[0045] 40-60 parts of epoxy resin, 30-40 parts of o-cresol novolac epoxy resin, 30-35 parts of nano-zinc oxide, 30-40 parts of cerium oxide, 20-40 parts of castor oil polyoxyethylene ether, 10- 18 parts, 12-16 parts of quartz powder, 4-6 parts of organic silicon, 3-8 parts of zinc stearate, 4-7 parts of ethylene glycol butyl ether, 3-7 parts of modified smectite, 10- 20 servings.

[0046] Among them, the auxiliary agents include brighteners, dispersants, leveling agents, thickeners and curing agents, wherein the mass ratio of brighteners, dispersants, leveling agents, thickeners and curing agents is 1-1.5: 2-5: 2-4: 1-4: 3-7.

[0047] Wherein, the whitening agent is one or a mixture of two or more of stilbene derivatives, phenylpyrazoline derivatives, benzimidazole derivatives, and phenylpyrazole derivatives; the dispersant is barium stear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com