Aerogel modified LED-UV scalding-resistant paint and preparation method and using method thereof

An aerogel modification and aerogel technology, which is used in fireproof coatings, epoxy resin coatings, coatings, etc., can solve problems that affect the convenience and service life of furniture, and the fullness of water-based paint films is worse than oily and oily. The problem of long drying time of the paint can achieve the effect of excellent cigarette butt ironing and non-blackening performance, fast curing rate, and dense and smooth paint film surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

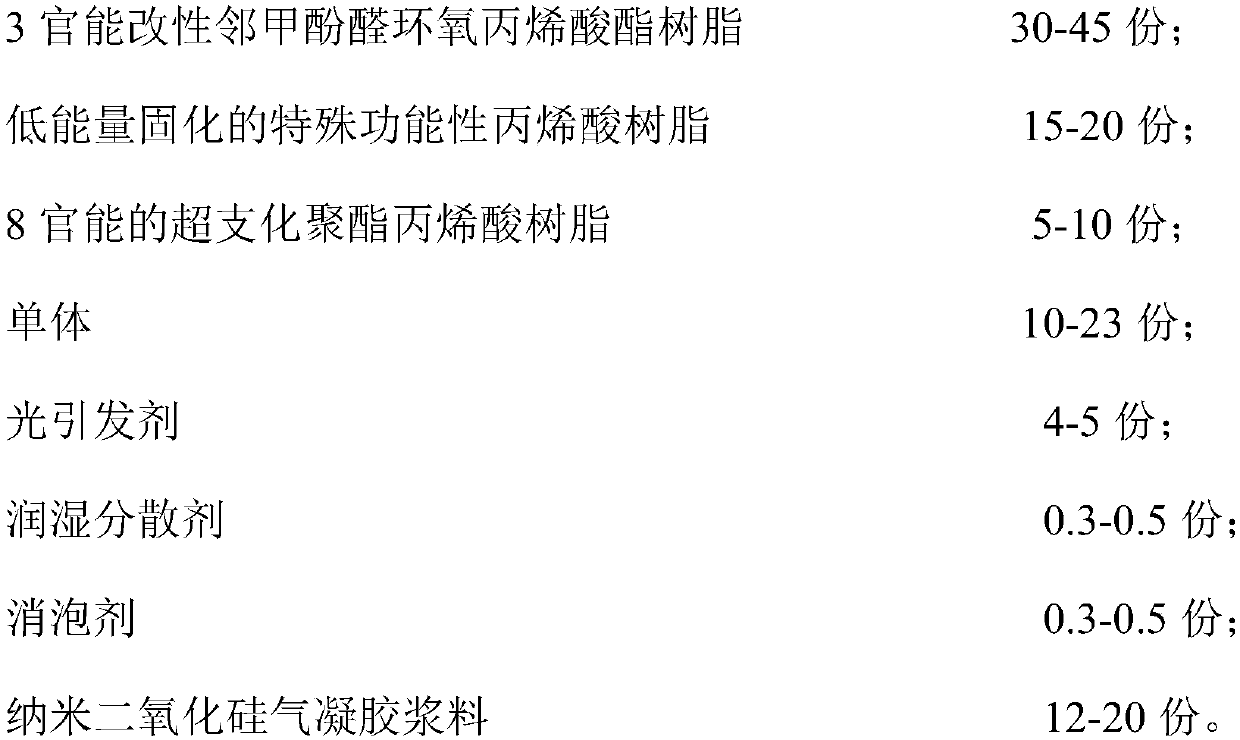

[0037]Step 1. Under the condition of avoiding sunlight or ultraviolet light irradiation, mix 30kg of 3-functional modified o-cresol novolac epoxy acrylate resin, 20kg of special functional acrylic resin cured by low energy, and 10kg of 8-functional hyperbranched polyester acrylic resin Add 23kg of monomer into the paint container and disperse evenly, then add 4kg of photoinitiator and 0.3kg of wetting and dispersing agent in sequence, and stir for more than 5 minutes at a stirring speed of 500 rpm until uniform, and keep the mixture during stirring Material temperature is less than 50°C;

[0038] Step 2: Add 0.4 kg of defoamer and 12 kg of nano-silica airgel slurry to the mixed material obtained in step 1, and stir and disperse for 25 minutes at a speed of 800 rpm to prepare the modified airgel of the present invention. Permanent LED-UV heat-resistant paint, paint liquid performance testing.

[0039] The obtained airgel modified LED-UV hot-resistant coating is brushed or spra...

Embodiment 2

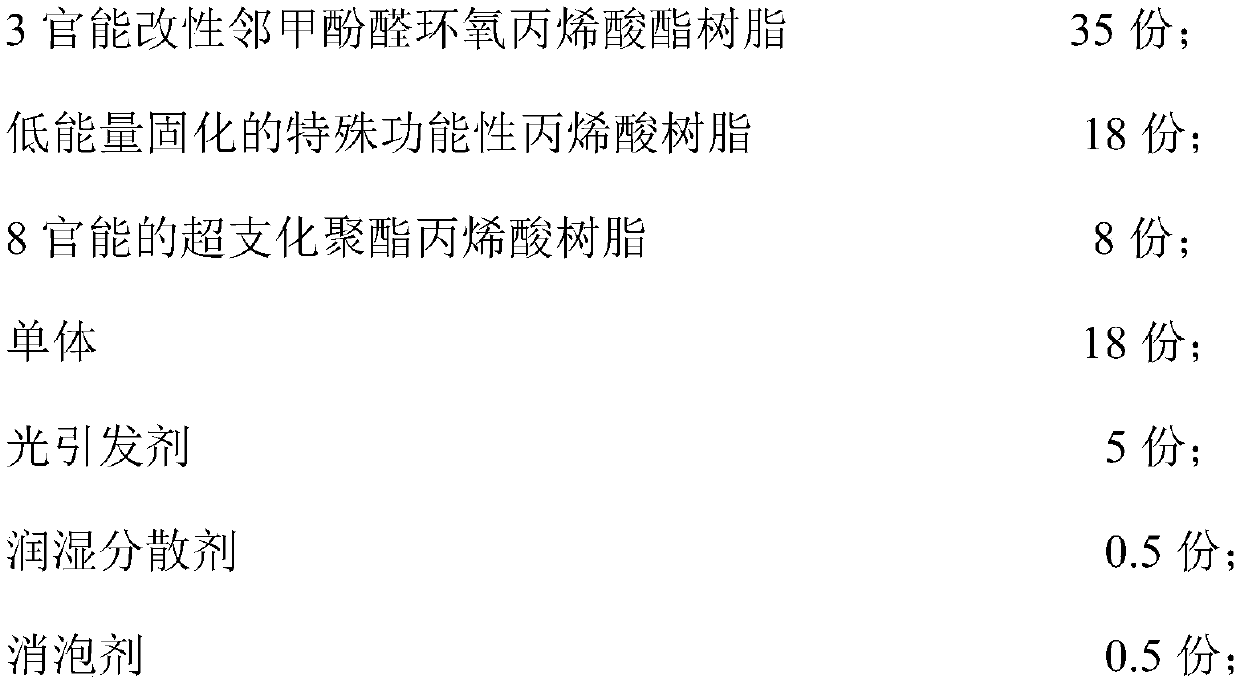

[0042] Step 1. Under the condition of avoiding sunlight or ultraviolet light, 35 kg of 3-functional modified o-cresol novolac epoxy acrylate resin, 18 kg of special functional acrylic resin cured by low energy, and 8 kg of 8-functional hyperbranched polyester acrylic resin Add 18kg of monomer into the paint container and disperse evenly, then add 5kg of photoinitiator and 0.5kg of wetting and dispersing agent in sequence, and stir for more than 5 minutes at a stirring speed of 600 rpm until uniform, and keep the mixture during stirring Material temperature is less than 50°C;

[0043] Step 2. Add 0.5 kg of defoamer and 15 kg of nano-silica airgel slurry to the mixed material obtained in step 1, and stir and disperse for 25 minutes at a speed of 900 rpm to prepare the modified airgel of the present invention. Permanent LED-UV heat-resistant paint, paint liquid performance testing.

[0044] The obtained airgel modified LED-UV hot-resistant coating is brushed or sprayed, accordin...

Embodiment 3

[0047] Step 1. Under the condition of avoiding sunlight or ultraviolet light irradiation, mix 40kg of 3-functional modified o-cresol novolac epoxy acrylate resin, 16kg of low-energy curing special functional acrylic resin, and 7kg of 8-functional hyperbranched polyester acrylic resin Add 13kg of monomer into the paint container and disperse evenly, then add 4.5kg of photoinitiator and 0.4kg of wetting and dispersing agent in turn, and stir for more than 5 minutes at a stirring speed of 700 rpm until uniformly mixed. The temperature of the mixed material is less than 50°C;

[0048] Step 2: Add 0.4 kg of defoamer and 18 kg of nano-silica airgel slurry to the mixed material obtained in step 1, and stir and disperse for 25 minutes at a speed of 1000 rpm to prepare the modified airgel of the present invention. Permanent LED-UV heat-resistant paint, paint liquid performance testing.

[0049] The obtained airgel modified LED-UV hot-resistant coating is brushed or sprayed, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com