Sludge enhanced baking-free brick and preparation method thereof

A technology of avoiding burning bricks and sludge, applied in the field of building materials, to achieve the effects of reducing vegetation damage, improving compressive strength, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

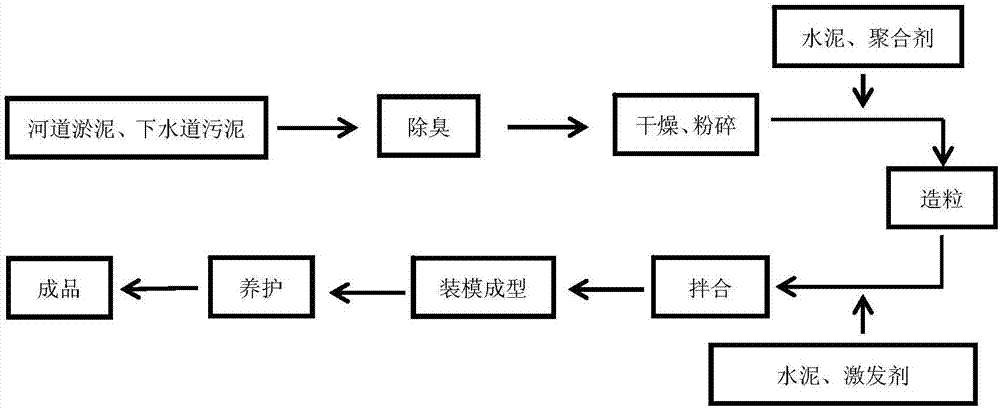

[0036] The invention also provides a method for preparing sludge-reinforced unburned bricks, figure 1 It is the flow chart of the production process of the sludge reinforced unburned brick of the present invention, as figure 1 shown, including the following steps:

[0037] S100. Using river sludge and / or sewer sludge or activated sludge as the main raw material, after deodorization, drying and pulverization, mixing with cement and polymerizing agent and then granulating to form stabilized soil particles;

[0038] S200, uniformly mixing the stabilized soil particles with cement and activator, and pressing to form;

[0039] S300, curing under natural conditions for 7 to 14 days to obtain the burnt-free brick with residual mud and slag.

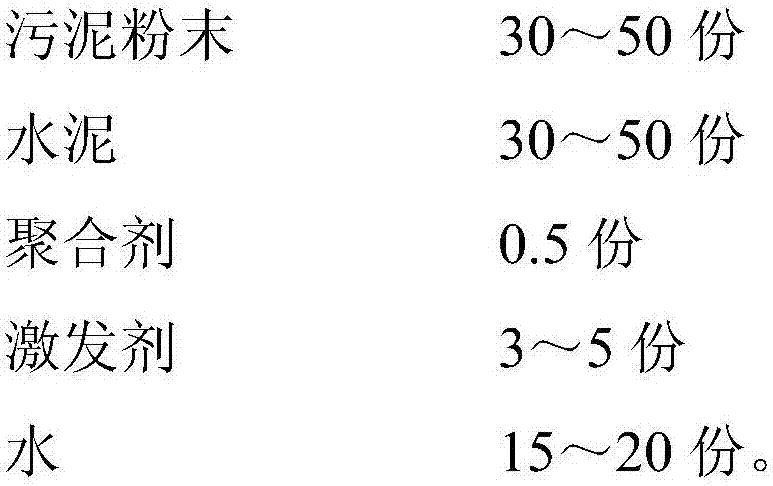

[0040] In another preferred embodiment of the present invention, in the step S100, the river sludge or sewage sludge is dried and dehydrated with a moisture content of <8% and a crushed particle size of <1 mm. The sludge powder is mixed with ...

Embodiment 1

[0045]Sludge reinforced unburned bricks are made by mixing river sludge, sewer sludge, cement, polymerizing agent and activator, granulating, pressing embryos, and curing. The quality of sludge dry powder, cement, polymerizing agent, activator and water The ratios are 50, 30, 0.5, 3, 15. The preparation process of sludge reinforced unburned bricks is as follows: figure 1 As shown, (1) Deodorize river silt and sewer sludge, dehydrate them, and obtain river silt and sewer sludge powder after pulverization; (2) Mix river silt and sewer sludge powder with cement, polymerization agent, and activator Mix, add appropriate amount of water, fully stir, and granulate after rolling; wherein the amount of granulated cement accounts for 50% of the single ratio cement; (3) mix the river sludge and sewage sludge particles with the remaining cement and activator, add Appropriate amount of water, fully stirred and rolled, then molded and pressurized at 400KN to form. After curing and demouldi...

Embodiment 2

[0047] Sludge reinforced unburned bricks are made by mixing river sludge, activated sludge, cement, polymerizing agent, and activator, granulating, pressing and pressing embryos, and curing. River sludge dry powder, activated sludge dry powder, cement, polymerizing agent, and activator The mass ratio with water is 40, 40, 0.5, 5, 15. The preparation process of sludge reinforced unburned bricks is as follows: figure 1 As shown, (1) dehydrate the river sludge and activated sludge after deodorization, and obtain river sludge and activated sludge powder through pulverization; (2) mix river sludge and activated sludge powder with cement, polymerization agent and activator Mix, add appropriate amount of water, fully stir, and granulate after rolling; wherein the amount of granulated cement accounts for 50% of the single ratio cement; (3) mix river sludge, activated sludge with remaining cement and activator, add appropriate amount Water, fully stirred and rolled, then molded and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com