SiC/SiC composite material surface coating system and preparation method thereof

A composite material and surface coating technology, which is applied in the field of coating system and its preparation, can solve problems such as the inability to improve the performance of SiC/SiC composite materials, and achieve reliability and overall service life, reliability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

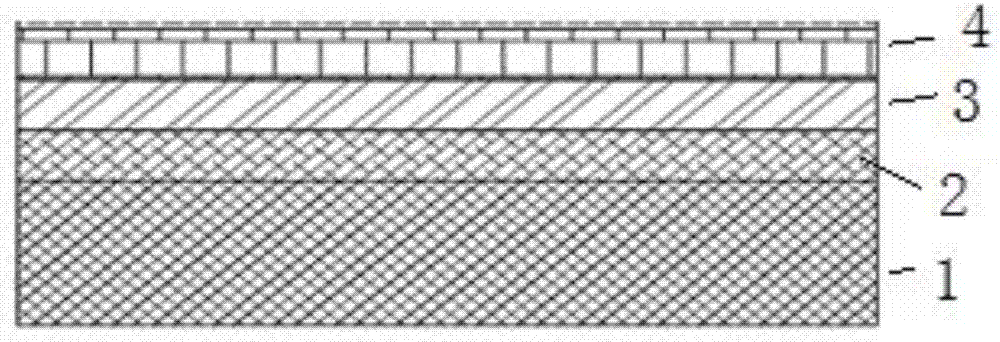

[0025] An embodiment of the present invention proposes a method for preparing a SiC / SiC composite surface coating system, which includes:

[0026] 1) Dip the SiC / SiC composite substrate in a polyborosilazane solution, solidify, dry, and pyrolyze at 700-900°C to obtain a SiC / SiC composite substrate with an anti-oxidation film on the surface;

[0027] Since the SiC / SiC composite material is a brittle material composite material, it is easy to produce microcracks under thermal shock. Firstly, a layer of Si-B-C-N multiphase system is used to seal the composite material fiber and matrix on the surface of the composite material by pyrolysis of polyborosilazane. Microcracks generated on the surface, the B element in it can react with oxygen to form glassy B in a high-temperature aerobic environment 2 o 3 , to heal microcracks in the composite system;

[0028] 2) dispersing the nano-SiC powder in a mixed solvent of polycarbosilane and xylene to obtain a slurry; wherein the weight ra...

Embodiment 1

[0035] An embodiment of the present invention proposes a method for preparing a SiC / SiC composite surface coating system, which includes:

[0036] 1) Dip the SiC / SiC composite substrate in polyborosilazane solution, add 5kg / cm 2 The pressure was repeated 3 times, then pressurized and dried at 100°C for 0.5h, and pyrolyzed at 700°C for 1h to obtain a SiC / SiC composite substrate with an anti-oxidation film on the surface;

[0037] 2) nano-SiC powder is dispersed in the mixed solvent of polycarbosilane and xylene, obtains slurry; Wherein, the weight ratio of nano-SiC powder, polycarbosilane and xylene is 2:6:4; Said The SiC / SiC composite material substrate with the surface anti-oxidation film is immersed in the slurry, and the pressure is 10kg / cm 2 , repeated 3 times, dried at 100°C for 3h, then put the sample into a vacuum sintering furnace at 1000°C for polycarbosilane ceramicization, the newly formed β-SiC and nano-SiC powder filled together the pores in the composite materia...

Embodiment 2

[0043] An embodiment of the present invention proposes a method for preparing a SiC / SiC composite surface coating system, which includes:

[0044] 1) Dip the SiC / SiC composite substrate in polyborosilazane solution, add 5kg / cm 2 The pressure was repeated 3 times, then pressurized and dried at 100°C for 0.5h, and pyrolyzed at 900°C for 1 hour to obtain a SiC / SiC composite substrate with an anti-oxidation film on the surface;

[0045] 2) nano-SiC powder is dispersed in the mixed solvent of polycarbosilane and xylene, obtains slurry; Wherein, the weight ratio of nano-SiC powder, polycarbosilane and xylene is 5:6:4; Said The SiC / SiC composite material substrate with the surface anti-oxidation film is immersed in the slurry, and the pressure is 10kg / cm 2 , repeated 3 times, dried at 100°C for 3h, then put the sample into a vacuum sintering furnace at 1200°C for polycarbosilane ceramicization, the newly formed β-SiC and nano-SiC powder filled together to fill the pores in the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com