Method used for co-production of 1,3-propanediol and 1,2-propanediol via hydrogenation of 3-hydroxypropionaldehyde aqueous solution

A technology of hydroxypropionaldehyde and propylene glycol, which is applied in the preparation of hydroxyl compounds, organic compounds, catalyst activation/preparation, etc., can solve the problems of unpublished selectivity and conversion data, and improve catalyst activity and catalyst efficiency. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

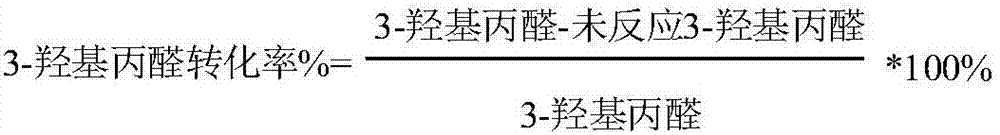

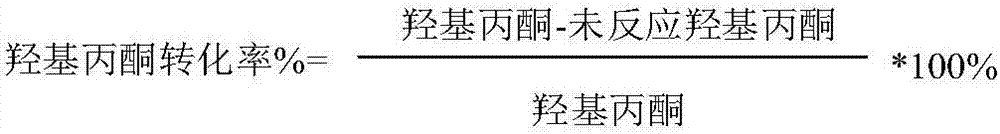

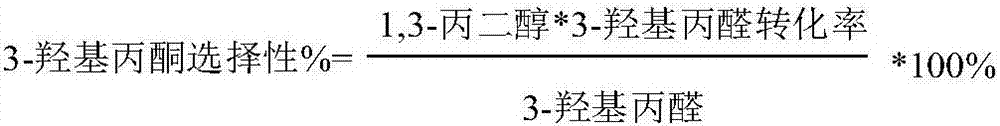

[0026] The catalyst used is Ni-Zr-Mn / Al 2 o 3 . The catalyst weight components are: Ni=35%, Zr=3%, Mn=2%, and the rest is carrier Al 2 o 3 , the carrier is Al 2 o 3 . Catalyst active components were prepared by gel method and attached to 20-40 mesh Al 2 o 3 superior. Take 5.0ml catalyst, seal and fix both ends with quartz sand, and use hydrogen to activate in situ before the reaction. The activation condition is: GHSV=2500h -1 , pressure 0.2MPa, keep at 150°C for 3h, keep at 200°C for 5h, and lower to 60°C after activation. The reaction temperature is 80°C, the hydrogen pressure is raised to 5.0MPa, the hydrogen-to-oil ratio is 80, the concentration of 3-hydroxypropanal aqueous solution is 35%, the concentration of hydroxyacetone aqueous solution is 10%, and the space velocity of 3-hydroxypropanal including hydroxyacetone is 0.7h -1 , Vent after 2 hours of reaction, take samples every 4h, use gas chromatography (calibrated), and calculate the conversion rate of raw ...

Embodiment 2

[0028] 3-hydroxypropionaldehyde including hydroxyacetone space velocity 0.3h -1 , other conditions are identical with embodiment 1.

Embodiment 3

[0030] 3-hydroxypropionaldehyde including hydroxyacetone space velocity 1.0h -1 , other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com