Board with flame-retardant effects

A board and flame retardant technology, which is applied in the field of composite boards and their preparation, can solve problems such as lack of other functions, insufficient flame retardancy, and impact on human health, and achieve the goals of improving attention, enhancing capabilities, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

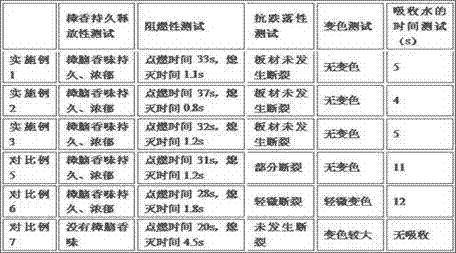

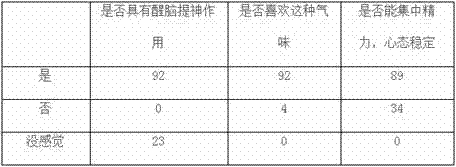

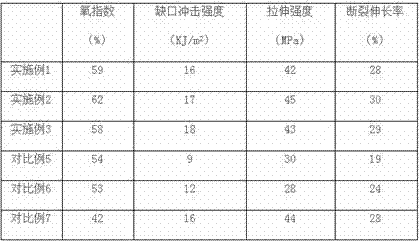

Examples

Embodiment 1

[0040] Example 1 A board with a flame-retardant effect, in parts by weight, the raw materials include:

[0041] 182 parts of sorghum straw powder, 20 parts of ginkgo powder, 11 parts of peanut shell powder, 23 parts of camphor powder, 8 parts of pot bottom ash, 16 parts of Huaijiao powder, 110 parts of polylactic acid resin powder, 15 parts of kaolin, 12 parts of modifier , Flame retardant 0-1 part.

[0042] The sorghum straw powder has a moisture content of ≤3% and a mesh size of 85 mesh;

[0043] The peanut shell powder has a mesh number of 40 and a crude fiber content of 62%;

[0044] The modifier is an aluminum-zirconium composite coupling agent; the aluminum-zirconium composite coupling agent is produced by Foshan Shengyi Chemical Co., Ltd.;

[0045] The kaolin has an oil absorption of 7.3g / 100g, a refractive index of 1.2, and a moisture content of 0.2%;

[0046] After adding kaolin, the ability of the modifier can be enhanced to further enhance the binding effect.

...

Embodiment 2

[0049] Example 2 A board with a flame-retardant effect, the raw materials include:

[0050] 205 parts of sorghum straw powder, 23 parts of ginkgo powder, 12 parts of peanut shell powder, 25 parts of camphor powder, 9 parts of pot bottom ash, 18 parts of Huaijiao powder, 125 parts of polylactic acid resin powder, 17 parts of kaolin, 13 parts of modifier , 1 part of flame retardant.

[0051] The sorghum straw powder has a moisture content of 2% and a mesh size of 90 mesh;

[0052] The peanut shell powder has a mesh number of 45 and a crude fiber content of 63%;

[0053] The modifier is an aluminum-zirconium composite coupling agent; the aluminum-zirconium composite coupling agent is produced by Foshan Shengyi Chemical Co., Ltd.;

[0054] The kaolin has an oil absorption of 7.4g / 100g, a refractive index of 1.2, and a moisture content of 0.2%;

[0055] After adding kaolin, the ability of the modifier can be enhanced, and the binding effect can be further enhanced; at the same t...

Embodiment 3

[0057]Embodiment 3 A board with a flame-retardant effect, the raw materials include:

[0058] 210 parts of sorghum straw powder, 25 parts of ginkgo powder, 10 parts of peanut shell powder, 27 parts of camphor powder, 8 parts of pot bottom ash, 20 parts of Huaijiao powder, 110 parts of polylactic acid resin powder, 21 parts of kaolin, 12 parts of modifier , 1 part of flame retardant.

[0059] The sorghum straw powder has a moisture content of 3% and a mesh size of 80 mesh;

[0060] The peanut shell powder has a mesh number of 50 and a crude fiber content of 65%;

[0061] The modifier is an aluminum-zirconium composite coupling agent; the aluminum-zirconium composite coupling agent is produced by Foshan Shengyi Chemical Co., Ltd.;

[0062] The kaolin has an oil absorption of 7.3g / 100g, a refractive index of 1.3, and a moisture content of 0.3%;

[0063] After adding kaolin, the ability of the modifier can be enhanced, and the binding effect can be further enhanced; at the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com