Waterborne epoxy anticorrosive coating containing graphene and preparing method and application thereof

A technology of water-based epoxy and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of shortened service life, reduced water resistance and anti-corrosion, difficult dispersion, etc., to reduce adverse effects and improve Dispersibility and the effect of reducing the amount of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

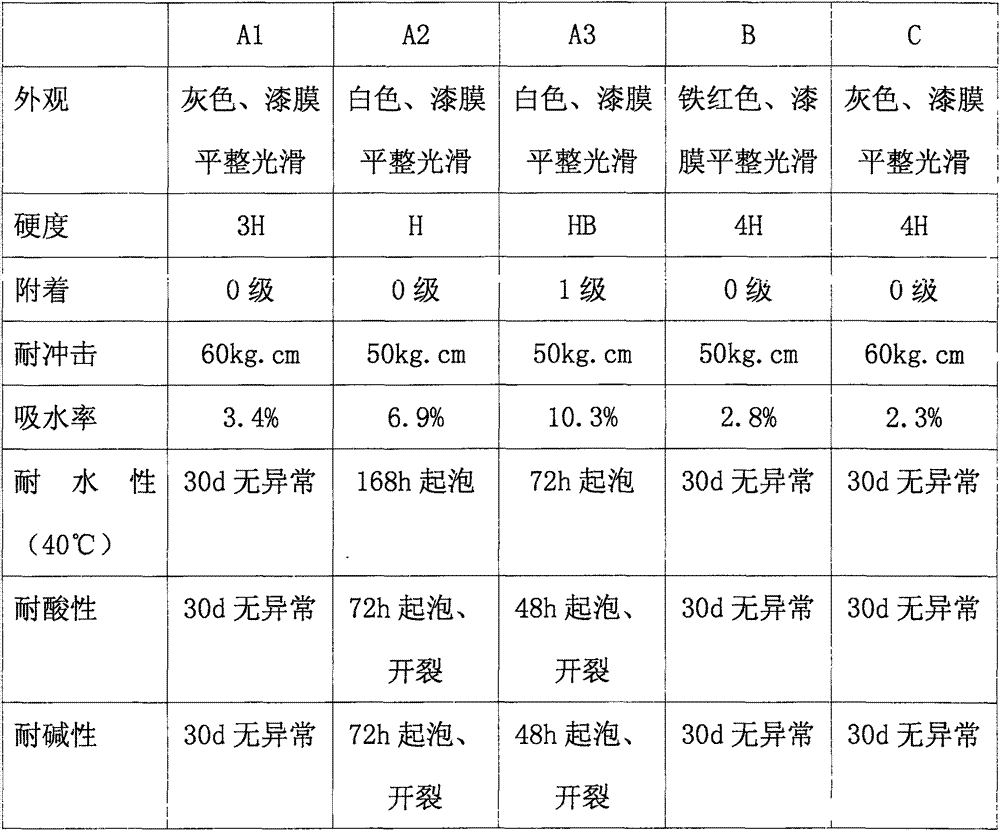

Embodiment 1

[0035] In parts by weight, add 10 parts of 1% graphene oxide aqueous solution, 30 parts of ethanol and 0.02 parts of hydrazine hydrate and mix well, then add hydrochloric acid dropwise to the mixed solution to adjust the pH to 1, and add 8 parts of ethyl orthosilicate dropwise. Esters, after reacting at 40°C for 20h, aging at 80°C for 48h under hydrothermal conditions, after suction filtration, the filter residue was dried at 60°C for 10h, and the dried solid was burned at 500°C for 6h under the protection of an inert gas to obtain silica modified Thermally reduced graphene oxide (SiO2@RGO) composite;

[0036] In parts by weight, 80 parts of epoxy resin with an epoxy equivalent of 190, 5 parts of ethylene glycol monobutyl ether solution containing 10% SiO2@RGO, and 5 parts of nonionic active epoxy emulsifier were added to the reactor. Stir and mix evenly at 50-80°C, add water slowly, and turn on the high-speed shearer at a speed of 1500-2500rpm, the viscosity increases accordi...

Embodiment 2

[0039]In parts by weight, add 50 parts by mass fraction of 1% graphene oxide aqueous solution, 20 parts of ethanol, and 0.01 part of hydrazine hydrate and mix well, then add hydrochloric acid dropwise to the mixed solution to adjust the pH to 1.5, and add 9 parts of tetrabutyl silicate dropwise Esters, after reacting at 40°C for 25h, aging at 90°C for 36h under hydrothermal conditions, after suction filtration, the filter residue was dried at 80°C for 7h, and the dried solid was burned at 500°C for 7h under the protection of an inert gas to obtain silica modified Thermally reduced graphene oxide (SiO2@RGO) composite, the silica-modified graphene obtained by this preparation method has amphiphilic characteristics and can replace part of the epoxy emulsifier;

[0040] In parts by weight, 10 parts of epoxy resin with an epoxy equivalent of about 400, 20 parts of propylene glycol monomethyl ether solution containing 10% SiO2@RGO, and 5 parts of nonionic active epoxy emulsifier at 6...

Embodiment 3

[0043] In parts by weight, add 30 parts by mass fraction of 1% graphene oxide aqueous solution, 30 parts of ethanol, and 0.04 parts of hydrazine hydrate, mix well, add hydrochloric acid to the mixed solution to adjust the pH to 1, and add 10 parts of ethyl orthosilicate dropwise Esters, after reacting at 40°C for 20h, aging at 120°C for 24h under hydrothermal conditions, after suction filtration, the filter residue was dried at 100°C for 5h, and the dried solid was burned at 500°C for 10h under the protection of an inert gas to obtain silica-modified Thermally reduced graphene oxide (SiO2@RGO) composite, the silica-modified graphene obtained by this preparation method has amphiphilic characteristics and can replace part of the epoxy emulsifier;

[0044] In parts by weight, 80 parts of epoxy resin with an epoxy equivalent of 800, 20 parts of solid-containing 10% SiO2@RGO ethylene glycol monobutyl ether solution, and 5 parts of nonionic active epoxy emulsifier were added to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com