Data acquisition and error prevention PLC control method in cylinder cover conveying process

A technology of data acquisition and control method, which is applied in the field of mechanical processing, can solve the problems of not conforming to the current production status of the enterprise, cumbersome process, unsuitable for the production of blank parts, etc., to achieve the advantages of automatic mechanical production, accurate data collection, stable and stable data collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

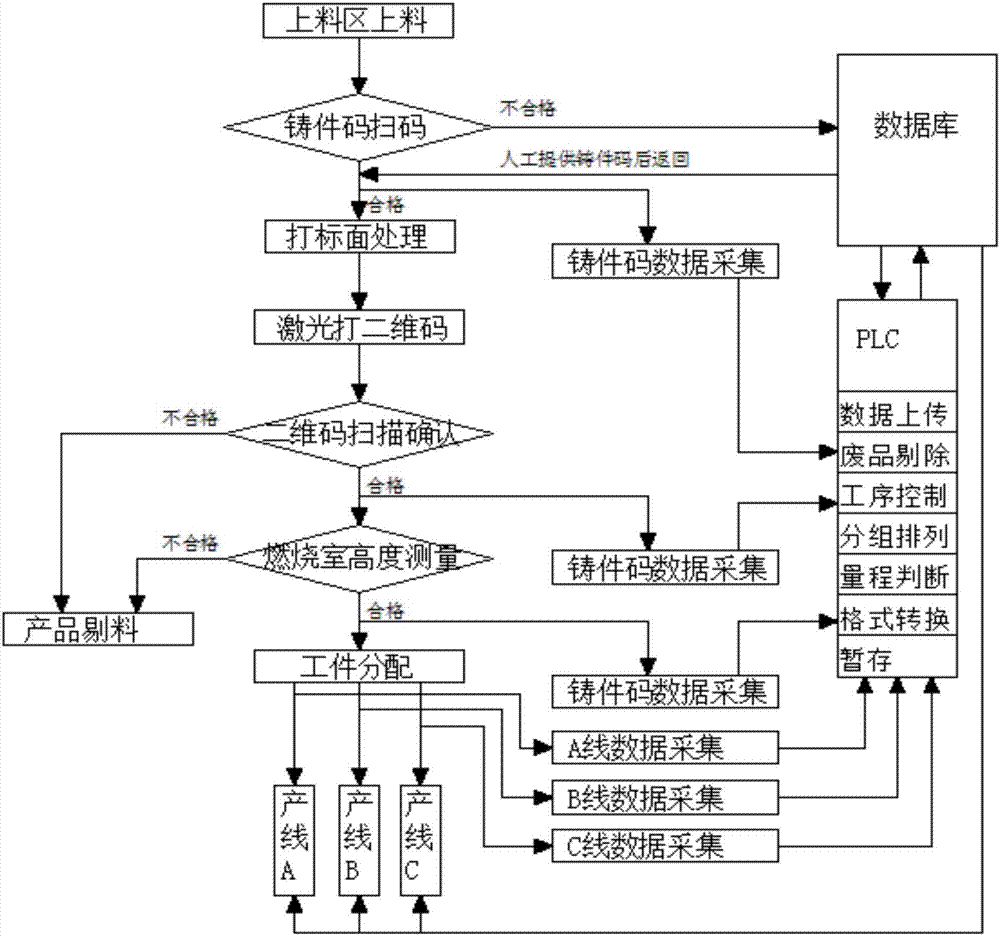

[0025] Example 1, such as Figure 1-2 Shown:

[0026] A PLC control method for data acquisition and error prevention in the process of cylinder head transmission. Before the workpiece enters the machine tool for processing, the blank is transferred from the feeding area to the machine tool by the transmission device. The cylinder head on the transmission line must pass through the casting code in turn. Scanning, marking surface treatment, laser printing QR code, QR code confirmation, combustion chamber height measurement and size out-of-tolerance waste discharge process; each process is arranged continuously;

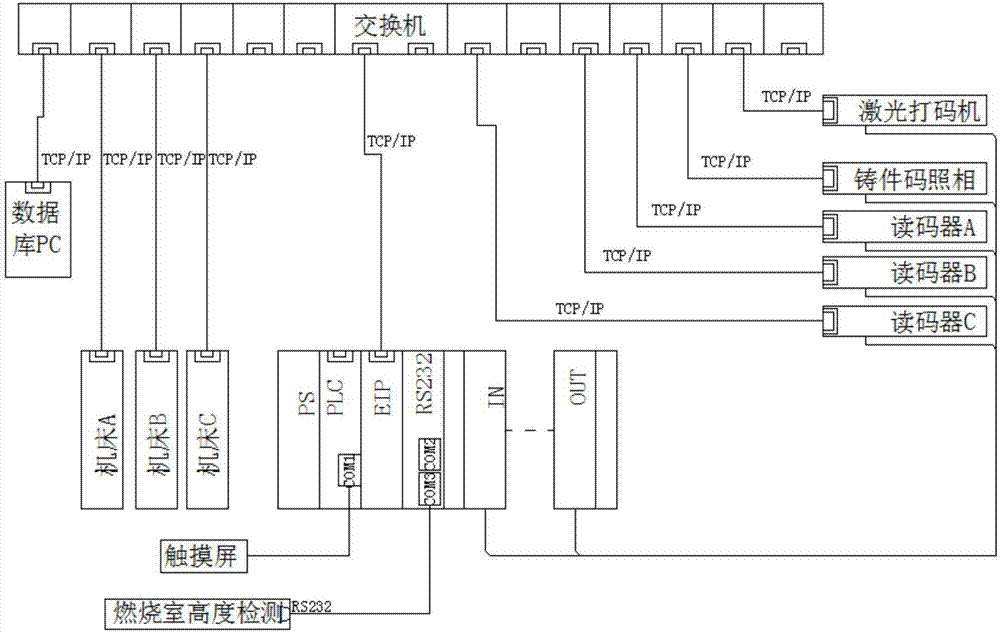

[0027] The PLC is connected to the scanning camera and the laser coding machine through Ethernet communication, and the PLC is connected to the combustion chamber height tester through RS232 communication to collect casting code information, laser printing two-dimensional code and combustion chamber size data. Then upload the correct product data and corresponding flag...

Embodiment 2

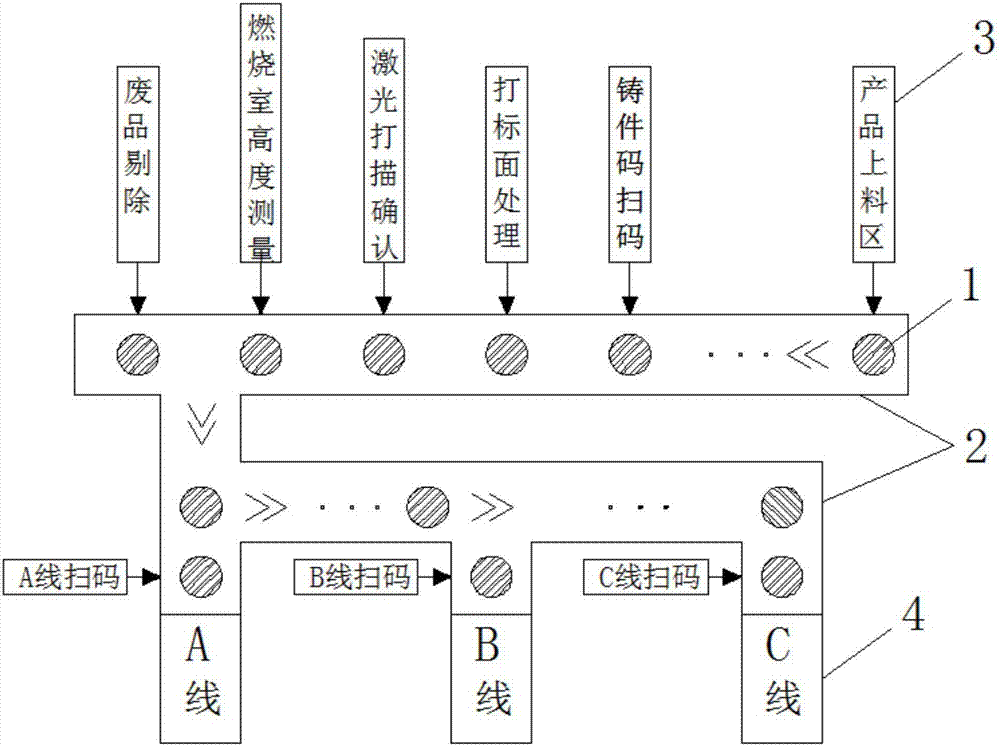

[0039] Example 2, such as image 3 Shown:

[0040] image 3 It is the layout diagram of the functional process of conveying workpieces in the present invention. The functional area 3 is set along the conveying line 2. From right to left, it is the product loading area, casting code scanning area, marking surface processing, laser printing confirmation, burning Chamber height measurement and waste rejection; in the line section after the waste rejection of the conveyor line 2, several machine tool processing lines 4 are set; the cylinder head casting 1 is placed through the product feeding area, conveyed along the conveyor line 2, and passed through the casting The data is collected by scanning the code. If the scanned code data is qualified, the marking surface processing will continue, and the waste products with unqualified data will be rejected; the workpieces that fail to scan the code will be input into the database PC by manual input; the products after the marking surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com