Novel perovskite manganese-based oxide thin film material and preparation method therefor

A technology of manganese-based oxide and thin-film materials, applied in the field of material science, to achieve the effects of easy realization, significant resistance change, and high magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

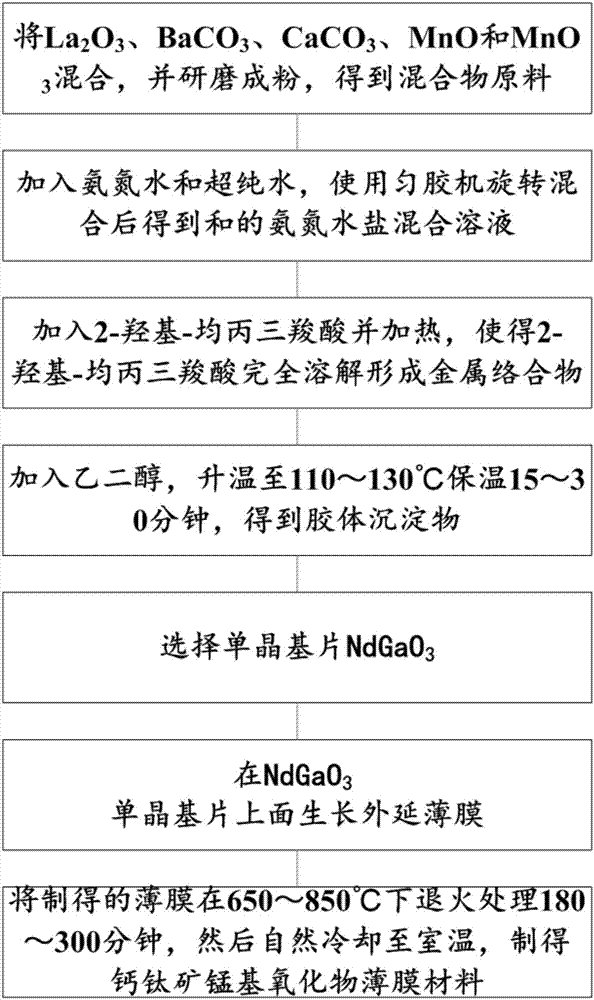

[0024] like figure 1 Shown, a kind of preparation method of novel perovskite manganese-based oxide film material comprises the following steps:

[0025] (1) La 2 o 3 、BaCO 3 , CaCO 3 , MnO and MnO 3 Mix and grind into powder to obtain the mixture raw material;

[0026] (2) Ammonia nitrogen water and ultrapure water are added to the mixture raw material obtained in step (1), and La(NO 3 ) 3 Ba(NO 3 ) 2 Ca(NO 3 ) 2 and Mn(NO 3 ) 2 Ammonia nitrogen water salt mixed solution;

[0027] (3) Add 2-hydroxyl-mesotricarboxylic acid to the ammonia nitrogen aqueous salt solution in step (2) and heat, so that the 2-hydroxyl-mesan tricarboxylic acid is completely dissolved to form a metal complex;

[0028] (4) Add ethylene glycol to the metal complex obtained in step (3), heat up to 110-130° C. and keep warm for 15-30 minutes to obtain a colloidal precipitate;

[0029] (5) Select single crystal substrate NdGaO 3 ;

[0030] (6) in NdGaO 3 Epitaxial La grown on a single crys...

Embodiment 1

[0035] Step (1): 12g rare earth metal oxide La 2 o 3 , 3.5g alkaline earth metal oxide CaCO 3 , and 11gMnO 3 Evenly mixed into raw materials;

[0036] Step (2): Grind the mixed raw materials fully in an agate mortar and store in a ceramic container, and add 2-hydroxy-propanetricarboxylic acid to heat, so that the 2-hydroxy-propanetricarboxylic acid is completely dissolved to form a metal complexes;

[0037] Step (3): Add ethylene glycol to the obtained metal complex, raise the temperature to 110-130°C and keep it warm for 15-30 minutes to obtain a colloidal precipitate;

[0038] Step (4): heating and cooling the obtained colloidal precipitate at 180-240° C. to obtain superfine powder;

[0039]Step (5): The ceramic container is naturally cooled to room temperature, and the product in the ceramic container is taken out, and pressed into tablets at room temperature and a pressure of 15 MPa;

[0040] Step (6): Annealing at a high temperature at 1200-1600° C. for 6-8 hours, a...

Embodiment 2

[0043] Step (1): 12g rare earth metal oxide La 2 o 3 , 5.0g alkaline earth metal oxide BaCO 3 , and 11gMnO 3 Evenly mixed into raw materials;

[0044] Step (2): Grind the mixed raw materials fully in an agate mortar and store in a ceramic container, and add 2-hydroxy-propanetricarboxylic acid to heat, so that the 2-hydroxy-propanetricarboxylic acid is completely dissolved to form a metal complexes;

[0045] Step (3): Add ethylene glycol to the obtained metal complex, raise the temperature to 120-145°C and keep it warm for 20-35 minutes to obtain a colloidal precipitate;

[0046] Step (4): heating and cooling the obtained colloidal precipitate at 200-260° C. to obtain superfine powder;

[0047] Step (5): The ceramic container is naturally cooled to room temperature, and the product in the ceramic container is taken out, and pressed into tablets at room temperature and a pressure of 15 MPa;

[0048] Step (6): annealing at a high temperature at 1300-1700° C. for 6-8 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com