Method for treating pig farm feces through outside fermenting bed

A fermentation bed and manure technology, applied in animal houses, applications, animal husbandry, etc., can solve problems such as waste of labor, difficult treatment of manure in large-scale pig farms, and biogas fermentation is affected by seasonal temperature, etc., to reduce production The effect of reducing the volume and treatment volume, thoroughly collecting and treating manure, and eliminating hidden dangers of disease transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

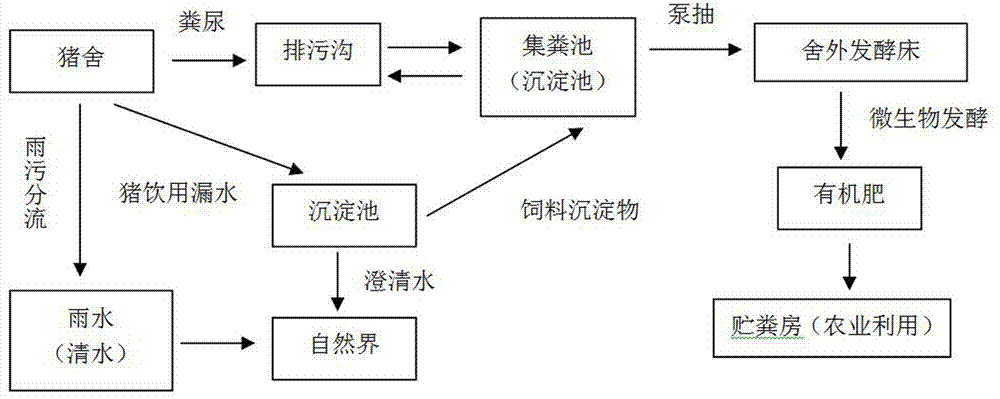

[0023] Such as figure 1 Shown, a kind of method for processing pig farm excrement in fermented bed outside house, specifically:

[0024] (1) Build a fermentation bed outside the pig house. The pig house is connected to the rain and sewage diversion tank, sedimentation tank, and sewage ditch respectively, and the sewage ditch is connected to the fermentation bed through the septic tank; 2 The standard production of each head, the width of the fermentation bed is 4.5-6.5 meters, the length depends on the needs, ranging from tens of meters, the shoulder height is 1.4-1.5 meters, the top height is 2.4-2.5 meters, the wall height is about 1 meter, and the tube spacing is 1 Rice, covered with plastic film, made into a cuboid according to the style of vegetable plastic greenhouses; 2 Effective volume construction of / 100 heads;

[0025] (2) Laying of fermentation materials: Lay the fermentation materials evenly in layers from bottom to top in the order of litter, bacteria, excremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com