Chicken feed and preparation method thereof, as well as application of residual cordyceps militaris culture medium

A technology for chicken feed and culture medium, applied in the application, animal feed, animal feed and other directions, can solve the problems of pollution, waste of resources and the environment, and achieve the effect of improving the ecological environment, increasing feed resources, and improving the quality of eggs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

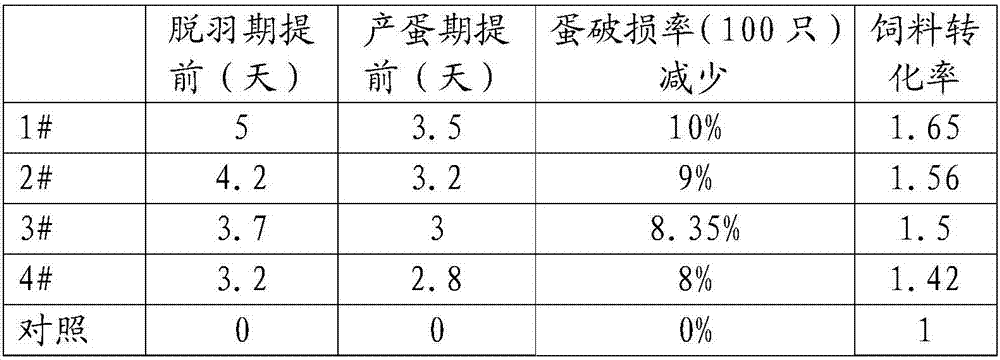

Examples

Embodiment 1

[0021] Example 1: Pretreatment of Cordyceps militaris culture medium residues, the method of treatment is water steaming at 80°C for 80 minutes, and then irradiating with ultraviolet light for 50 minutes. Mix 30kg of the treated Cordyceps militaris medium residue, 15kg of water peanuts, 12kg of mulberry leaves, 40kg of corn flour, 1kg of wheat bran, and 2kg of soybean meal, and grind them into 20-40 mesh fine powder; 2) add the hemicellulose Enzyme 0.2kg, cellulase 0.20kg, protease 0.28kg, amylase 0.32kg, glucoamylase 0.25kg. Adjust its pH value to 6.5-8.0, fully mix and stir for 20-43 hours; 3) take out after stirring evenly, dry it, pulverize it, and granulate it.

Embodiment 2

[0022] The preparation method and components of Example 2 are basically the same as those of Example 1, the only difference being: the pretreatment of the Cordyceps militaris culture medium residues, the treatment method is water steaming at 60°C for 60 minutes, and then irradiating with ultraviolet light for 50 minutes. With treated Cordyceps militaris culture medium residue 25kg, water peanut 10kg, mulberry leaf 10kg. Hemicellulase 0.14kg, cellulase 0.16kg, protease 0.20kg, amylase 0.30kg, glucoamylase 0.20kg.

Embodiment 3

[0023] The preparation method and components of Example 3 are basically the same as those of Example 1, the only difference being: the pretreatment of the Cordyceps militaris culture medium residues, the treatment method is steaming at 100°C for 100 minutes, and then irradiating with ultraviolet light for 20 minutes. With treated Cordyceps militaris culture medium residue 45kg, water peanut 20kg, mulberry leaf 15kg. Hemicellulase 0.30kg, cellulase 0.25kg, protease 0.35kg, amylase 0.35kg, glucoamylase 0.30kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com