Reactor and method with sludge discharge device for enhanced stable operation of aerobic granular sludge

An aerobic granular sludge, stable operation technology, applied in chemical instruments and methods, biological treatment devices, water/sludge/sewage treatment, etc. stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

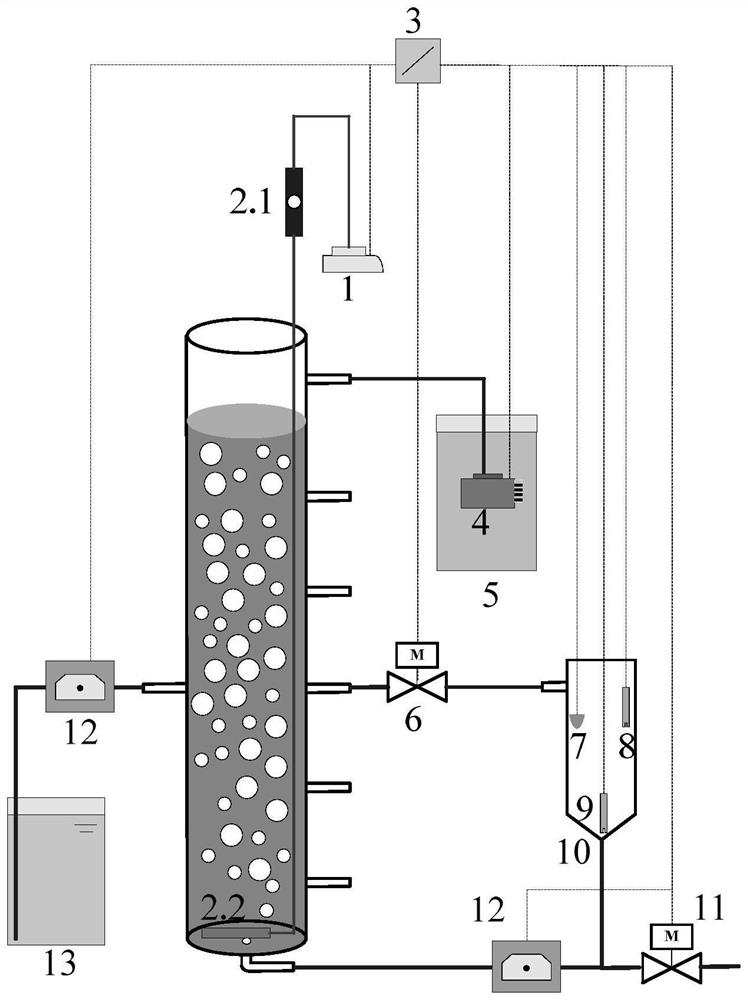

[0046] In this embodiment, the aerobic granular sludge process for treating urban sewage adopts a sequencing batch reactor (SBR) with an effective volume of 4.0 L. The main body of the reactor is a cylindrical plexiglass cylinder with a height of 50 cm and an inner diameter of 10 cm. , with an aspect ratio of 5. The reactor structure is as figure 1 As shown in the foregoing description, details are not repeated here.

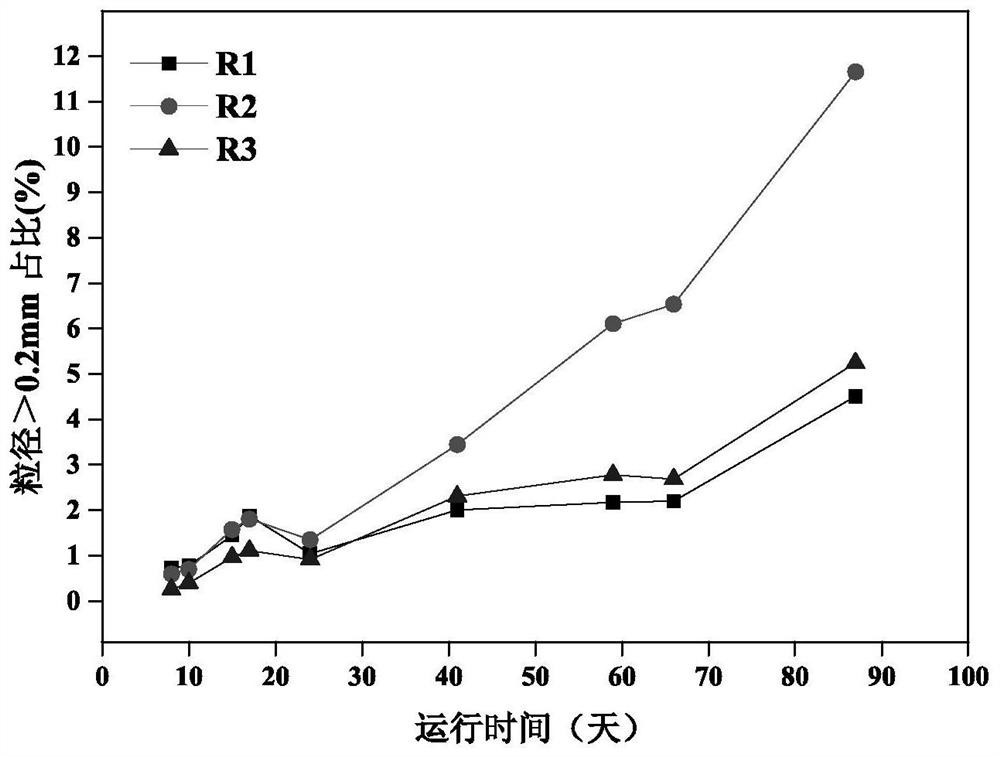

[0047] The inoculated sludge in this example is taken from the aeration tank of the municipal sewage treatment plant, and the Shannon index is 4.85, which means that there is a relatively high abundance of flora in the particles. The analysis of the flora structure at the phylum level found that Proteobacteria and Bacteroides Accounting for more than 60%, these bacteria are important flora in aerobic granular sludge, which can help the device to achieve rapid granulation of aerobic granular sludge

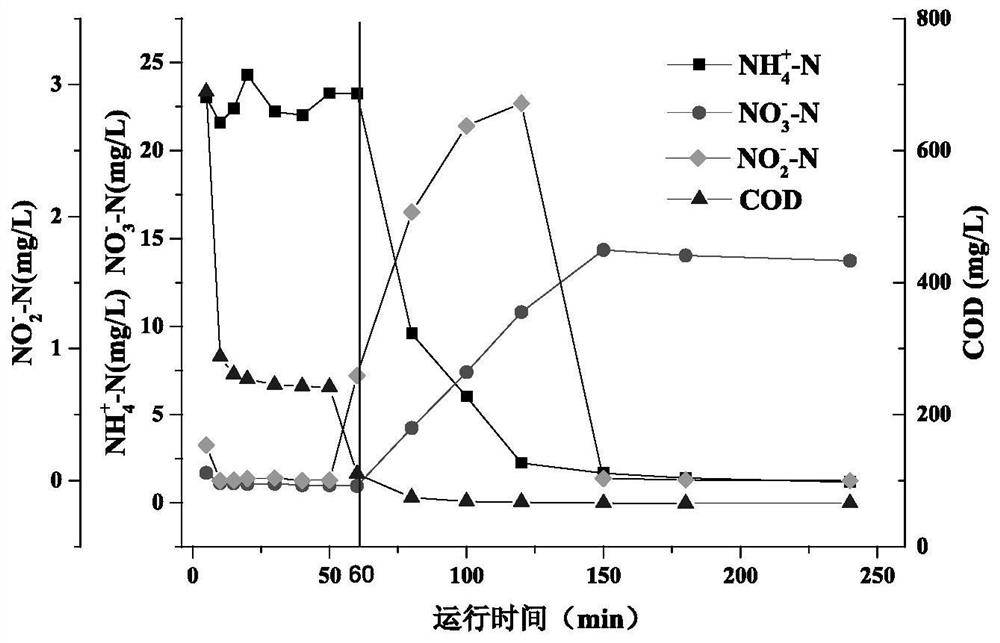

[0048] In this embodiment, the operation process of using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com