Treatment system and method of landfill leachate

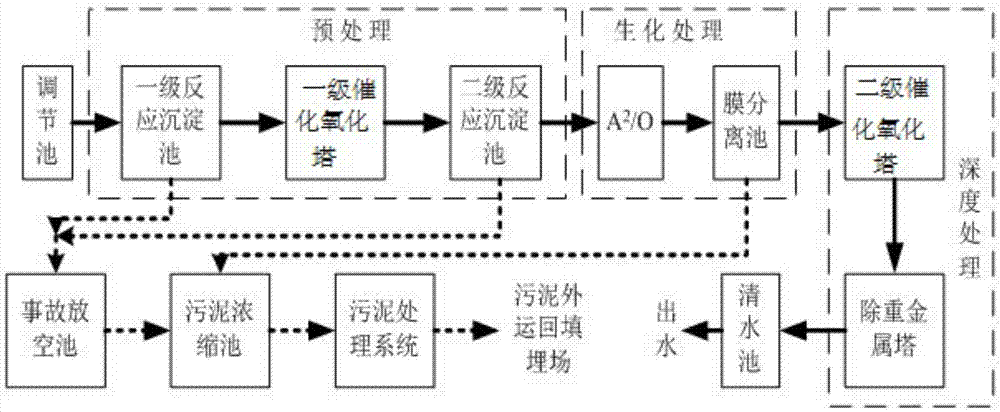

A landfill leachate and treatment system technology, applied in the direction of contaminated groundwater/leachate treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of large fluctuations in treatment volume, secondary pollution, frequent replacement, etc. , achieve the effect of low investment and operation cost, reducing COD and ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Pilot test of landfill leachate in Pingxiang, Jiangxi, raw water COD cr It is about 4000mg / L, the flocculant PAC is 150mg / L, PAM is 2mg / L, and the surface load of the primary reaction sedimentation tank is 0.5m 3 / m 2 h, the hydraulic retention time is 4h, and then it is introduced into a first-level advanced oxidation tower (ozone catalytic oxidation tower), and the ozone dosage is 75mg / m 3 , the hydraulic retention time is 1h, and then it is introduced into the secondary reaction sedimentation tank, and the surface load of the secondary reaction sedimentation tank is 0.5m 3 / m 2 h, the hydraulic retention time is 6h, and then pumped into the pre-acidification tank, the pre-acidification time is 4h, the pH value of the wastewater is adjusted to about 7, and then pumped into the anaerobic reactor. The anaerobic reactor used in this embodiment is UASB (upstream type multi-stage anaerobic reactor), the volume load of anaerobic reactor is 8kgCOD / m 3 d, the ascending fl...

Embodiment 2

[0054] A pilot test study was carried out on the landfill leachate in Pingxiang, Jiangxi. The raw water CODcr is about 7000mg / L, the flocculant PAC is 350mg / L, and the PAM is 5mg / L. The surface load of the primary reaction sedimentation tank is 1m 3 / m 2 h, the hydraulic retention time is 4h, and then introduced into the first-level advanced oxidation tower, the ozone dosage is 150mg / m 3 , the hydraulic retention time is 1h, and then it is introduced into the secondary reaction sedimentation tank, and the surface load of the secondary reaction sedimentation tank is 1m 3 / m 2 h, the hydraulic retention time is 6h, and then pumped into the pre-acidification tank, the pre-acidification time is 4h, and the pH value of the wastewater is adjusted to about 7 and pumped into the anaerobic reactor. The anaerobic reactor adopted in this embodiment is UASB (upflow type) Multi-stage anaerobic reactor), anaerobic reactor volume load 15kgCOD / m 3 d, the ascending flow rate is 6m / h, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com