Furnace chamber of a vertical tank type vacuum tempering furnace

A tempering furnace and hearth technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve problems such as prone to failure, large energy reactive power loss, and long preheating time, so as to quickly enter the working state and reduce heat energy loss , Increase the effect of heat convection space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

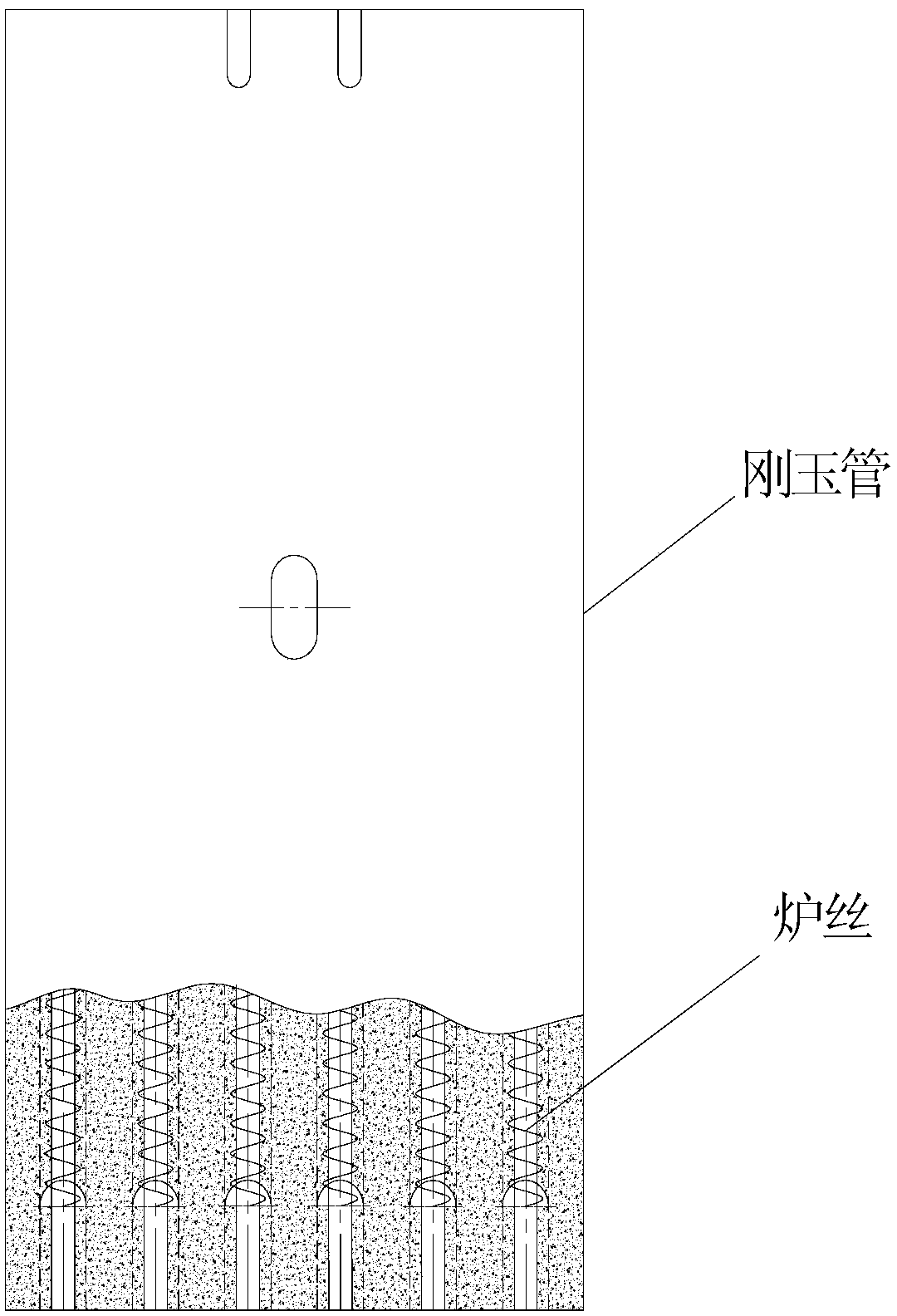

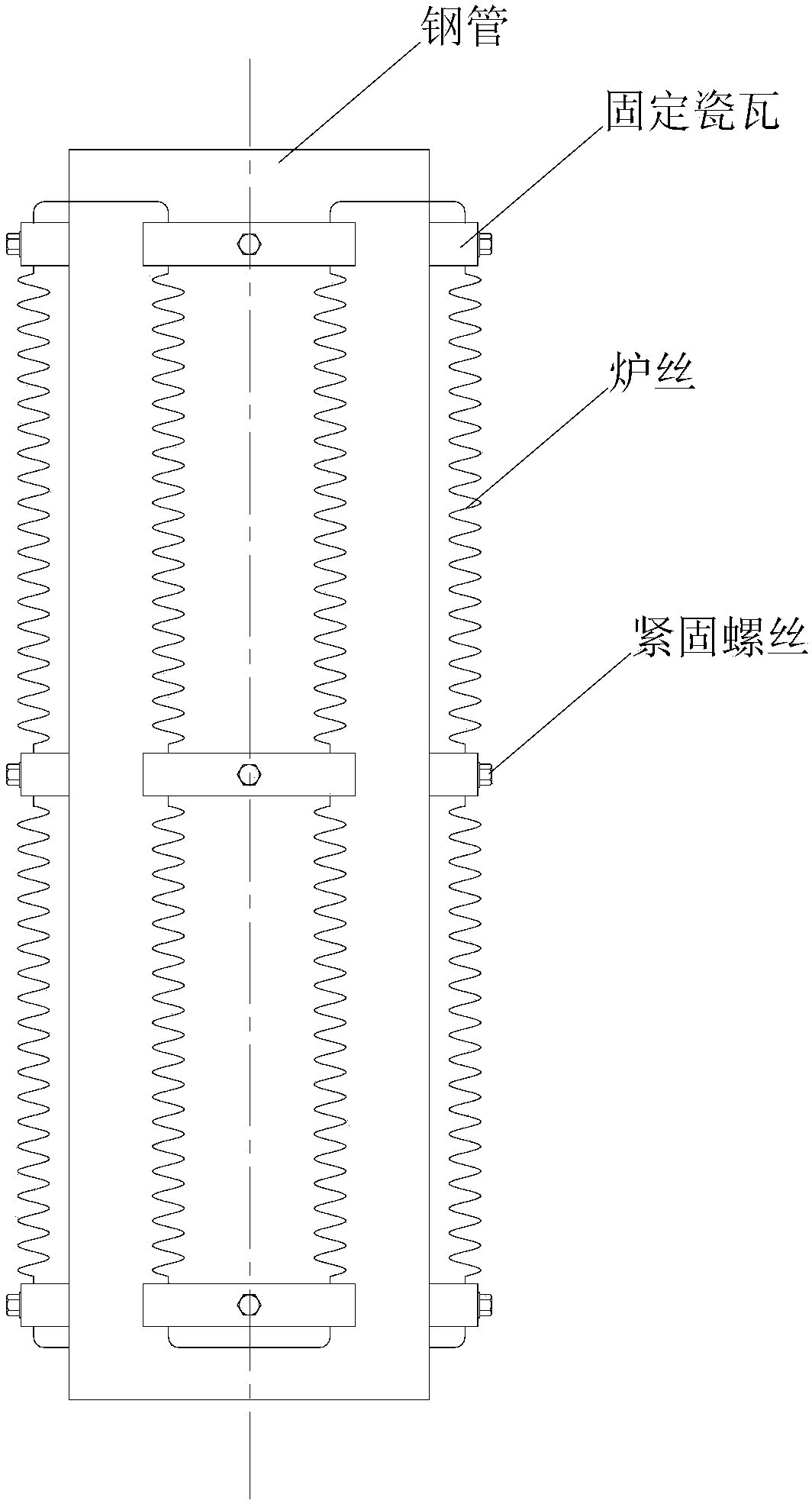

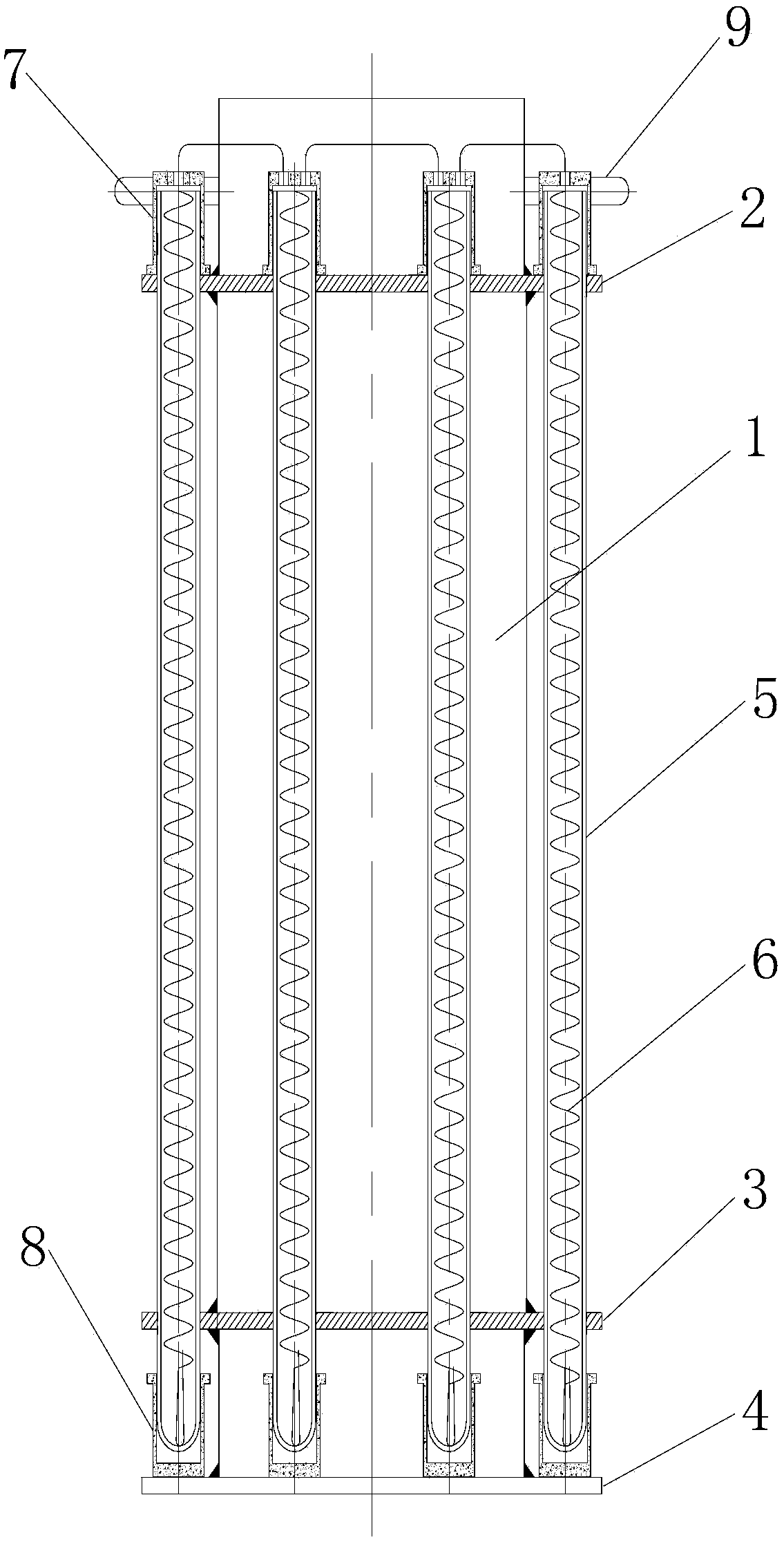

[0027] Embodiment 1: as image 3 As shown, the hearth of the vertical tank type vacuum tempering furnace of the present invention includes a furnace liner 1, a positioning plate, and a plurality of quartz glass tubes; the furnace liner 1 is processed with a positioning platform for installing a positioning plate, and the positioning plate includes an upper The positioning plate 2 and the lower positioning plate 3, the surface of the upper positioning plate 2 and the lower positioning plate 3 are respectively processed with uniform positioning holes for installing the quartz glass tube 5 (the number of holes depends on the power of the furnace), and the quartz glass tube 5 Fixed in the positioning holes in the upper positioning plate 2 and the lower positioning plate 3, the positioning method of the quartz glass tube 5 is the upper and lower positioning plate type; the upper positioning plate 2 and the lower positioning plate 3 are respectively welded on the positioning platform...

Embodiment 2

[0029] Embodiment 2: as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the positioning plate can only be the upper positioning plate 2, and the quartz glass tube 5 can only be fixed on the upper positioning plate 2, and the positioning method of the quartz glass tube 5 is the chassis Table hole type. Other components and design ideas are the same as those in Embodiment 1, and will not be repeated here.

[0030] Figure 5 It is the overall schematic diagram of the vertical tank type vacuum tempering furnace of the present invention. One end of the pipeline in the chamber enters the furnace cavity, and the other end is connected with the vacuum unit.

[0031] Because the present invention adopts stainless steel tube or ceramic material as the furnace liner, the furnace wire assembly with quartz tube protection is placed in the positioning plate at both ends of the steel tube furnace lining, and the furnace liner made of stainless steel or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com