Europium doped cobalt ferrite composite and preparation method thereof

A technology of cobalt ferrite and composite materials, applied in iron compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of less pollution, easy reaction, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

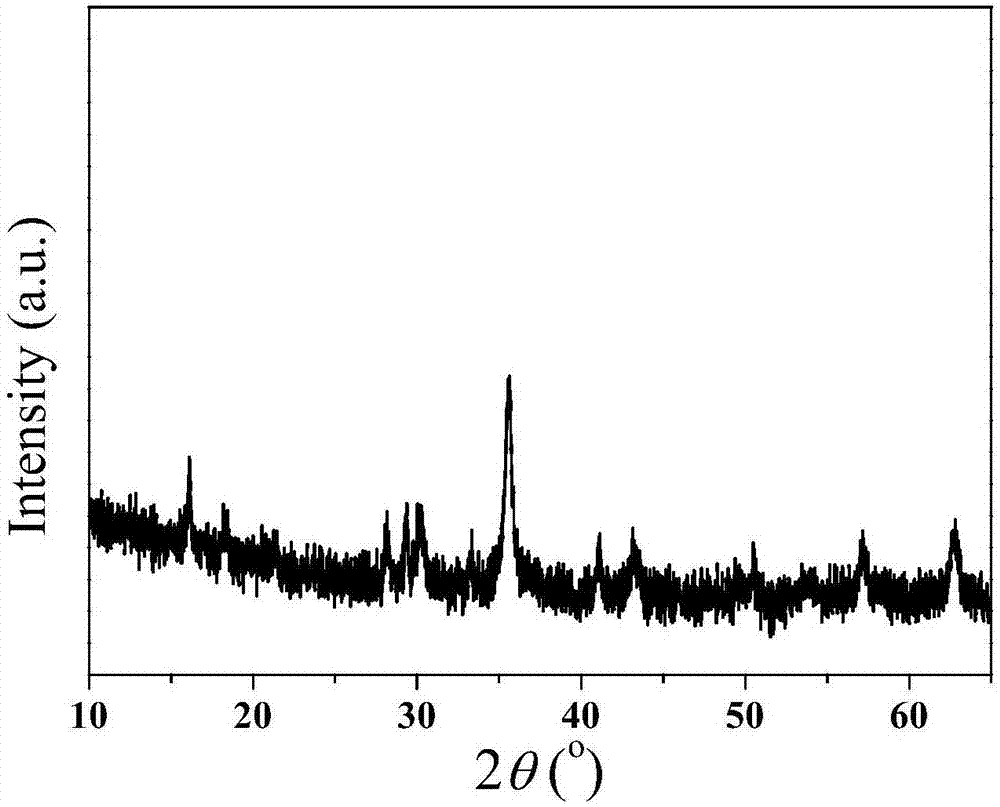

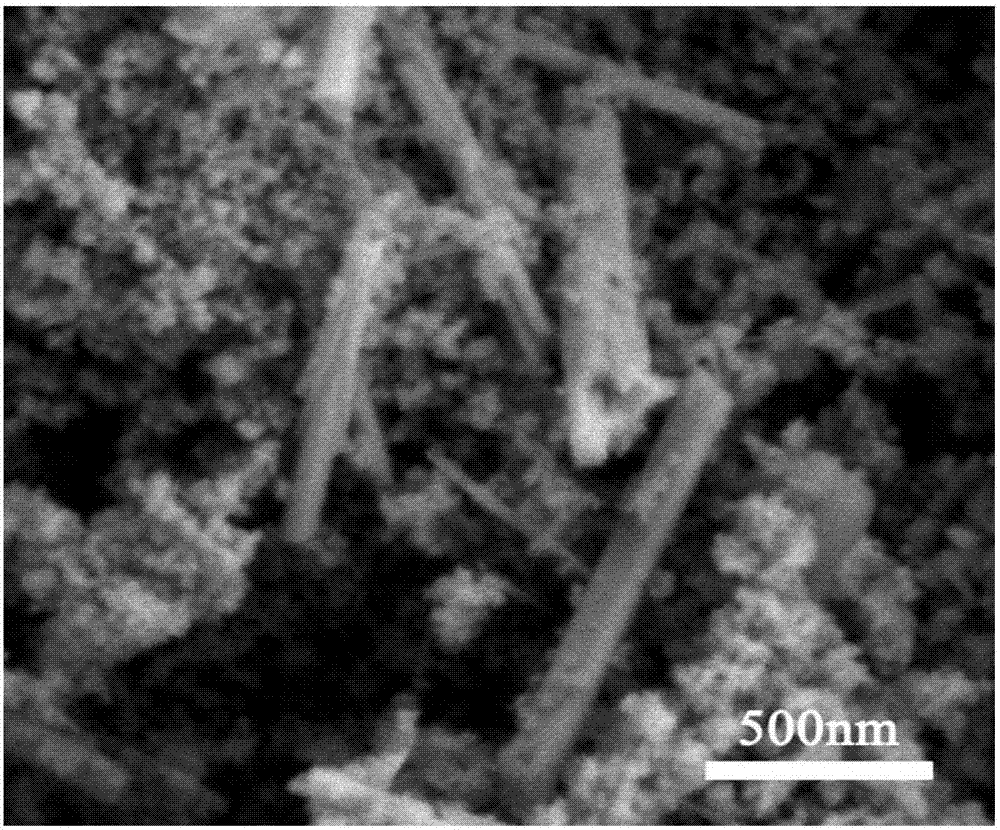

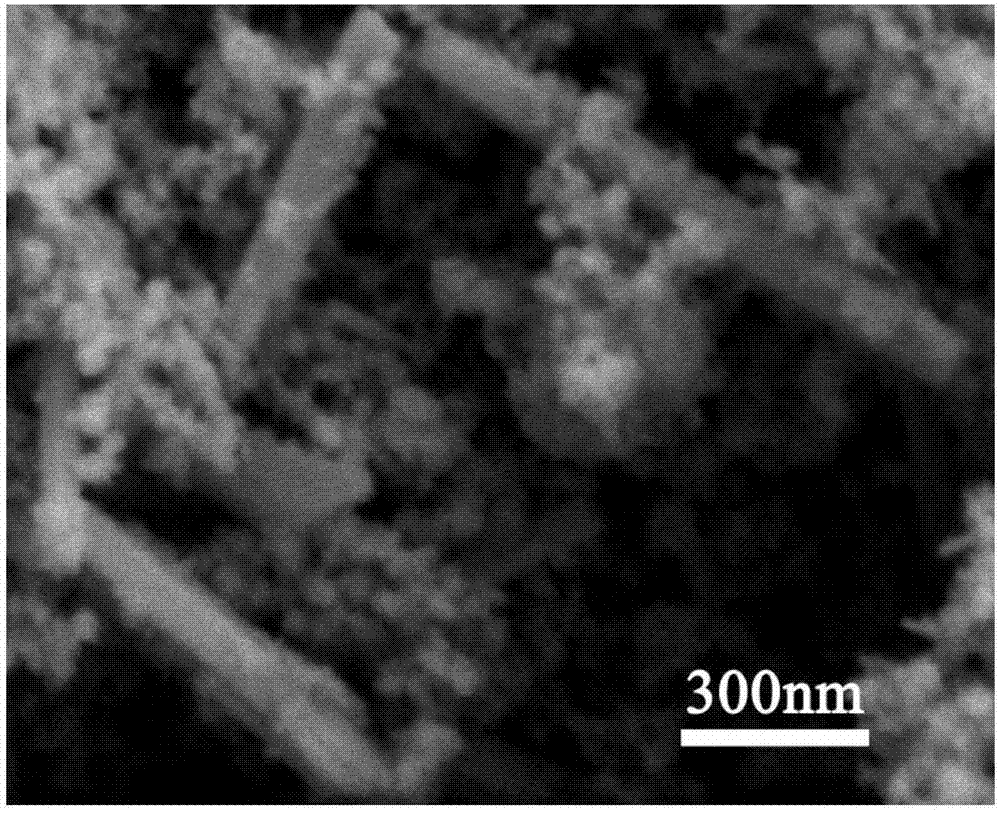

[0029] A europium-doped cobalt ferrite (Co 0.8 Eu 0.2 Fe 2 o 4 Namely x=0.8) the preparation method of composite material, method step is as follows:

[0030] S1: Add 1.6mmol Co(NO 3 ) 3 ·6H 2 O, 0.4mmol Eu(NO 3 ) 3 ·6H 2 O and 4mmol Fe(NO 3 ) 3 9H 2 O, and fully stirred evenly, adding NaOH solution with a concentration of 5mol / L dropwise, adjusting the pH of the solution to 11, and continuously stirring for 20min.

[0031] S2: Move the solution into a reaction kettle, and react at a constant temperature of 180°C for 10 hours; after the reaction is completed, cool the solution to room temperature, and repeatedly centrifuge and wash the precipitate with deionized water and ethanol until the solution becomes neutral.

[0032] S3: Finally, dry in a vacuum oven at 60°C for 12 hours to obtain Co with x=0.8 0.8 Eu 0.2 Fe 2 o 4 Europium-doped cobalt ferrite composites.

Embodiment 2

[0034] A europium-doped cobalt ferrite (Co 0.85 Eu 0.15 Fe 2 o 4 Namely x=0.85) the preparation method of composite material, method step is as follows:

[0035] S1: Add 1.7mmol Co(NO 3 ) 3 ·6H 2 O, 0.3mmol Eu(NO 3 ) 3 ·6H 2 O and 4mmol Fe(NO 3 ) 3 9H 2 O, and fully stirred evenly, adding NaOH solution with a concentration of 5mol / L dropwise, adjusting the pH of the solution to 11.5, and continuously stirring for 20min.

[0036] S2: Move the solution into a reaction kettle, and react at a constant temperature of 180°C for 10 hours; after the reaction is completed, cool the solution to room temperature, and repeatedly centrifuge and wash the precipitate with deionized water and ethanol until the solution becomes neutral.

[0037] S3: Finally, dry in a vacuum oven at 60°C for 12 hours to obtain Co with x=0.85 0.85 Eu 0.15 Fe 2 o 4 Europium-doped cobalt ferrite composites.

Embodiment 3

[0039] A europium-doped cobalt ferrite (Co 0.9 Eu 0.1 Fe 2 o 4 Namely x=0.9) the preparation method of composite material, method step is as follows:

[0040] S1: Add 1.8mmol Co(NO 3 ) 3 ·6H 2 O, 0.2mmol Eu(NO 3 ) 3 ·6H 2 O and 4mmol Fe(NO 3 ) 3 9H 2 O, and fully stirred evenly, adding NaOH solution with a concentration of 5mol / L dropwise, adjusting the pH of the solution to 11.8, and continuously stirring for 20min.

[0041]S2: Move the solution into a reaction kettle, and react at a constant temperature of 180°C for 10 hours; after the reaction is completed, cool the solution to room temperature, and repeatedly centrifuge and wash the precipitate with deionized water and ethanol until the solution becomes neutral.

[0042] S3: Finally, dry in a vacuum oven at 60°C for 12 hours to obtain Co with x=0.9 0.9 Eu 0.1 Fe 2 o 4 Europium-doped cobalt ferrite composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com