PVC (Polyvinyl Chloride) pipe and preparation technology thereof

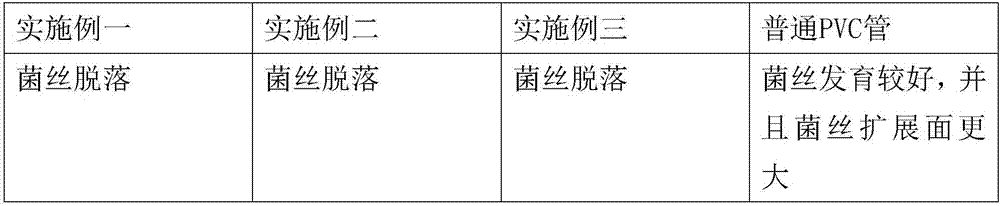

A PVC pipe and process technology, applied in the field of PVC pipe and its preparation process, can solve problems such as bursting, and achieve the effects of reducing thermal stress, improving rigidity and cutting performance, and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A PVC pipe, comprising: 150 parts of PVC, 8 parts of DBP, 8 parts of ethyl cellulose, 3.2 parts of tribasic sodium phosphite, 1 part of isooctyl dimethyl tin dithioacetate, hard 0.12 parts of fatty acid, 0.8 parts of pearl powder, 0.8 parts of chitosan, 0.15 parts of paraffin, 1.4 parts of talcum powder, 0.8 parts of polyethylene polyamine, 4 parts of calcium carbonate, 5 parts of triethanolamine, and 5 parts of phosphorothioate.

[0019] The PVC pipe also includes: 0.4 parts of zirconium silicate, 0.4 parts of nano-zinc oxide, 0.4 parts of carrageenan, and 0.6 parts of Lewis base in terms of components by weight.

[0020] A process for preparing PVC pipes, comprising the steps of:

[0021] (1) take each component according to parts by weight;

[0022] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minutes;

[0023] (3) Extrude the mixed material in a twin-screw extruder, wherein the temperature control parameter...

Embodiment 2

[0028] A PVC pipe comprising: 140 parts by weight of PVC, 5 parts of DBP, 5 parts of ethyl cellulose, 3 parts of tribasic sodium phosphite, 0.5 part of isooctyl dimethyl tin dithioacetate, hard 0.1 part of fatty acid, 0.5 part of pearl powder, 0.5 part of chitosan, 0.1 part of paraffin, 1.2 part of talcum powder, 0.5 part of polyethylene polyamine, 2 parts of calcium carbonate, 2 parts of triethanolamine, and 2 parts of phosphorothioate.

[0029] The PVC pipe also includes, by weight components: 0.3 parts of zirconium silicate, 0.3 parts of nano-zinc oxide, 0.3 parts of carrageenan, and 0.5 parts of Lewis base.

[0030] A process for preparing PVC pipes, comprising the steps of:

[0031] (1) take each component according to parts by weight;

[0032] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minutes;

[0033] (3) Extrude the mixed material in a twin-screw extruder, wherein the temperature control parameters are: hea...

Embodiment 3

[0038] A PVC pipe, comprising by weight components: 160 parts of PVC, 10 parts of DBP, 10 parts of ethyl cellulose, 3.5 parts of tribasic sodium phosphite, 2 parts of isooctyl dimethyl tin dithioacetate, hard 0.15 parts of fatty acid, 1 part of pearl powder, 1 part of chitosan, 0.2 parts of paraffin, 1.6 parts of talcum powder, 1 part of polyethylene polyamine, 6 parts of calcium carbonate, 8 parts of triethanolamine, and 8 parts of phosphorothioate.

[0039] The PVC pipe also includes: 0.5 parts of zirconium silicate, 0.5 parts of nano-zinc oxide, 0.5 parts of carrageenan, and 0.8 parts of Lewis base in terms of components by weight.

[0040] A process for preparing PVC pipes, comprising the steps of:

[0041] (1) take each component according to parts by weight;

[0042] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minutes;

[0043] (3) Extrude the mixed material in a twin-screw extruder, wherein the temperature con...

PUM

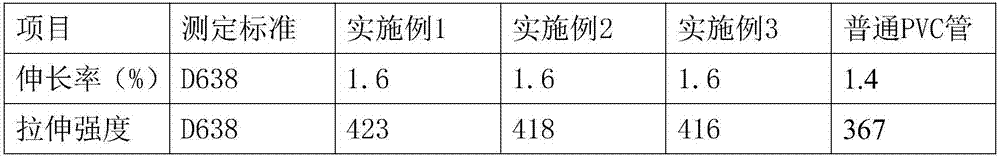

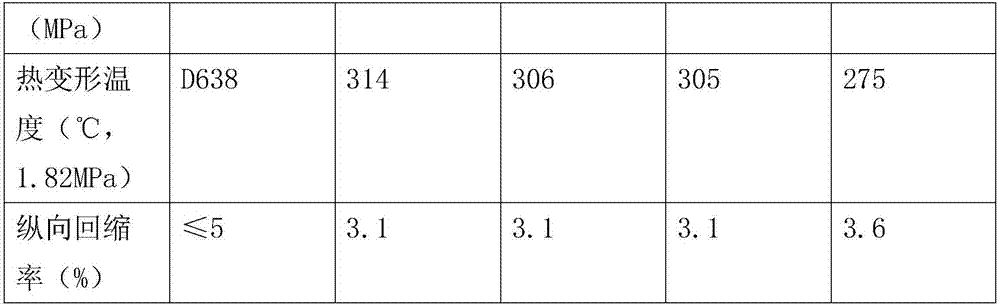

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com