Carbon-loaded gold atom cluster catalyst and application thereof in catalytic oxidation of glucose

A technology of atomic clusters and catalysts, which is applied in the field of carbon-supported gold atomic cluster catalysts and its application in the catalytic oxidation of glucose, can solve the problems of poor reusability of nano-gold catalysts, difficulties in scale-up production, and complicated preparation processes, and achieve broad industrial Application prospect, high stability and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

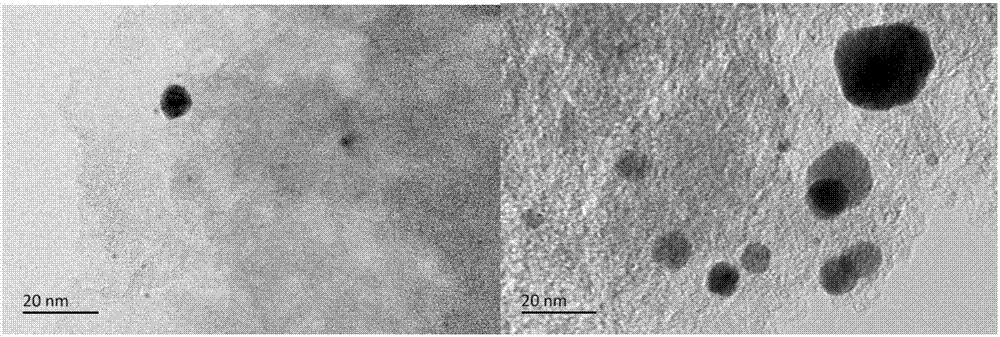

Embodiment 1

[0032] Catalyst preparation process: Weigh a certain amount of chloroauric acid into the flask, and add tetrahydrofuran solvent. Then add an appropriate amount of TOABr. After stirring for 1-10 minutes, add an appropriate amount of mercaptan or triphenylphosphine. Then stir for 10-30 minutes and add an appropriate amount of NaBH 4 (dissolved in ice water). Stir for 5-10 hours to stop the reaction. The product was washed with n-hexane and dichloromethane, and the precipitated solid was extracted with dichloromethane to obtain a gold atom cluster catalyst (AuNC) protected by thiol or triphenylphosphine. Weigh a certain amount of gold clusters dissolved in dichloromethane, then add an appropriate amount of activated carbon , Activated carbon is acidified before use, and stirred at room temperature for 7-8 hours. After the stirring was stopped, the samples were centrifuged and dried in a vacuum oven. Finally, the carbon-supported gold atom clusters are calcined at 120° C.-3...

Embodiment 2

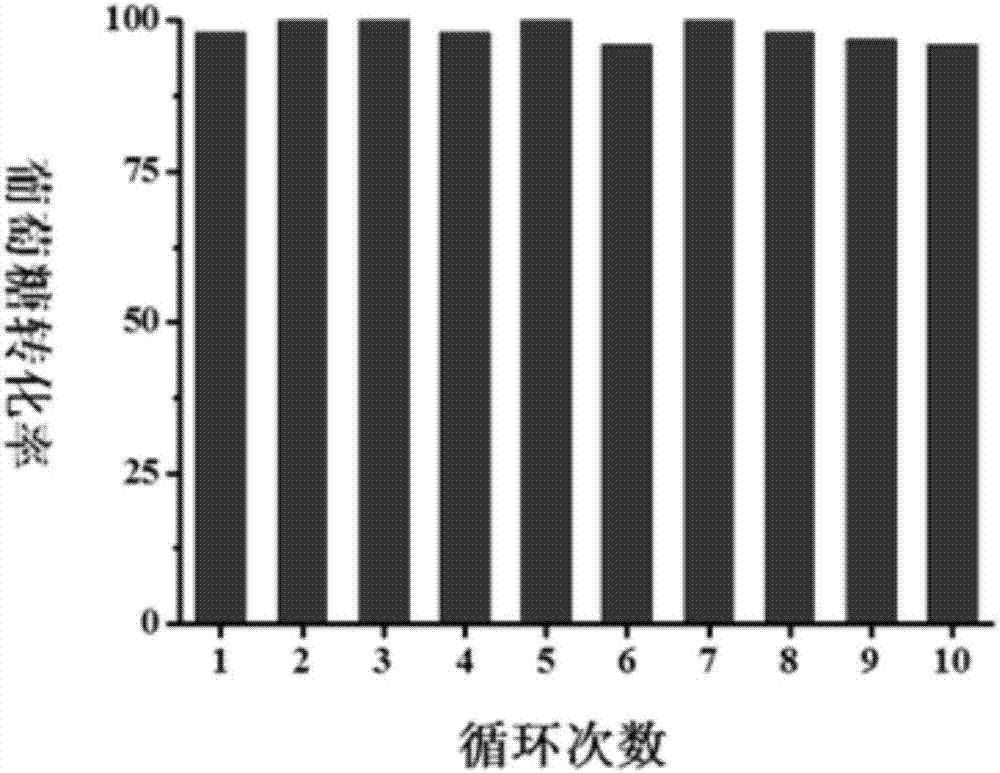

[0035] Catalytic conversion experiment: the gold atom cluster catalyst prepared in Example 1 was used as the catalyst. The concentration of glucose is 5%, the molar ratio of glucose and gold in the catalyst is 1000:1, oxygen is continuously introduced under stirring conditions, and the reaction temperature is kept at 60°C. During the reaction, NaOH solution is continuously added dropwise to keep the pH of the solution = 9.5 . Constant temperature reaction until the pH of the reaction system does not change, the reaction ends. Stand still after the reaction, wash and precipitate the catalyst for future use. The product was analyzed by HPLC, and the selectivity of sodium gluconate was 99%.

Embodiment 3

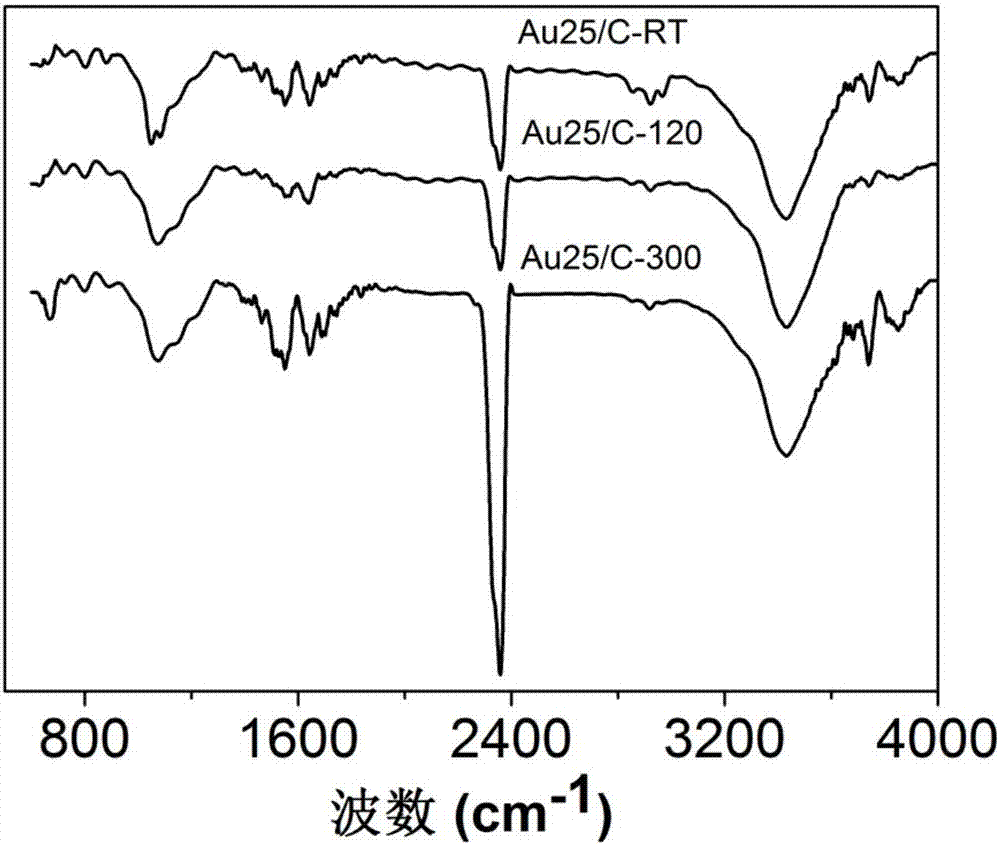

[0037] Catalytic conversion experiment: 1% AuNC / AC prepared in Example 1 was used as a catalyst, and the 1% AuNC / AC catalyst was subjected to air calcination at temperatures of 80°C, 120°C, 150°C, and 300°C. Carry out the glucose oxidation reaction after the treatment, keep the molar ratio of glucose and gold at 1000:1, feed oxygen continuously under the condition of constant stirring, keep the reaction temperature at 60°C, add NaOH solution dropwise during the reaction, keep the pH of the solution= 9.5. Constant temperature reaction until the pH of the reaction system does not change, the reaction ends. Stand still after the reaction, wash and precipitate the catalyst for later use, the effect of the treatment temperature of 1% AuNC / AC on its glucose oxidation reaction activity surface 1 (reaction time 15min).

[0038] surface 1

[0039] Processing temperature Glucose conversion rate% Sodium gluconate selectivity% other% unprocessed 65 98.3 1.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com