Flavonoid compound in damask rose waste residue as well as preparation method and application thereof

A technology of flavonoids and waste residues, applied in the field of phytochemistry, can solve the problem of low yield of rose essential oil, achieve the effect of relieving throat irritation and increasing sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

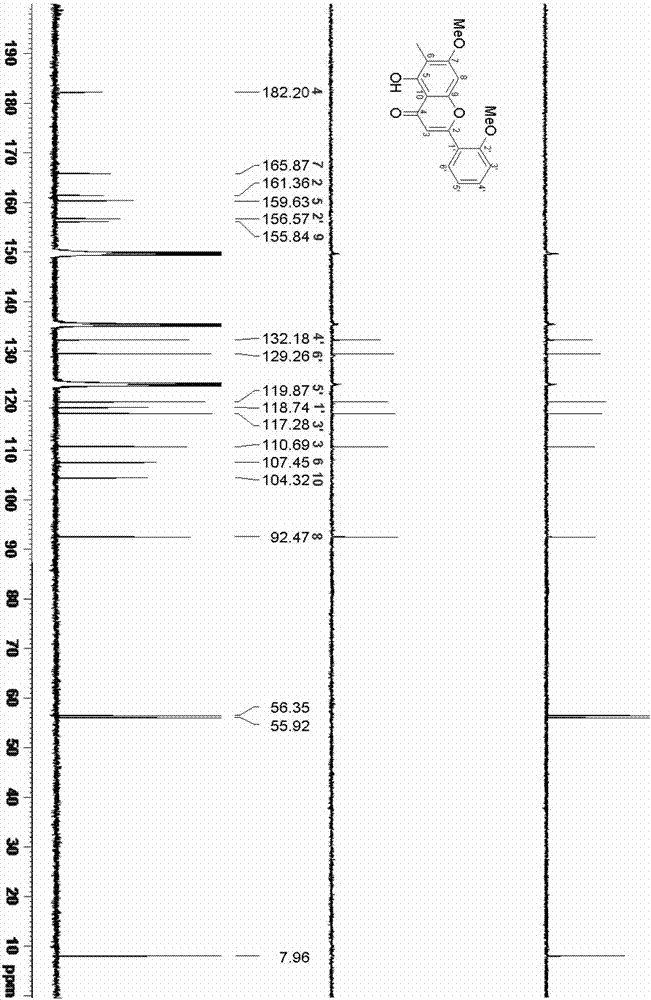

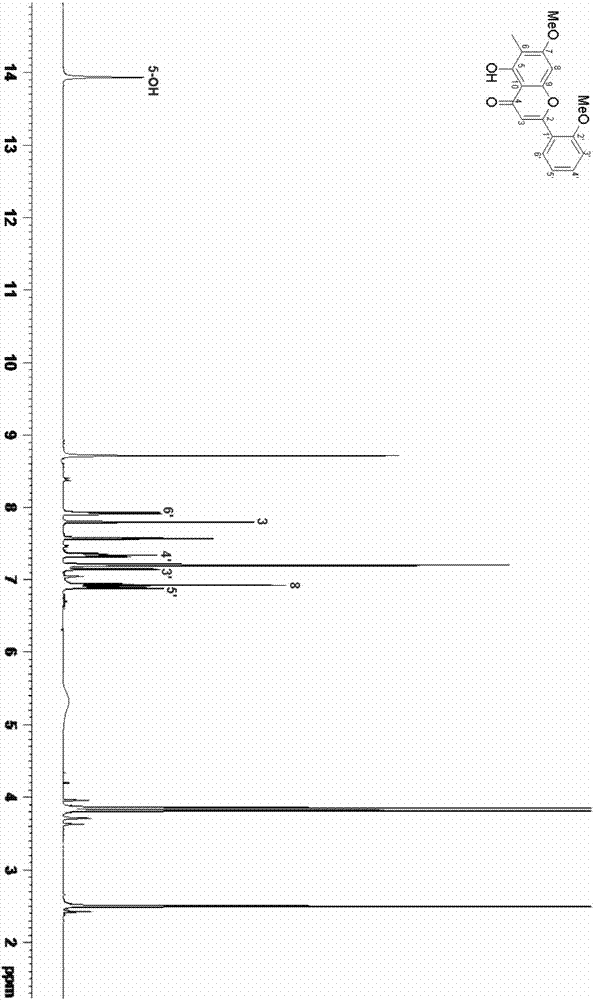

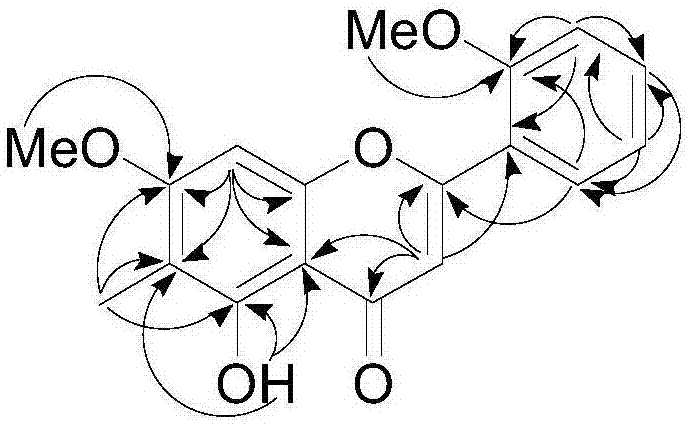

Image

Examples

preparation example Construction

[0049] The preparation method of the flavonoids of the present invention takes the waste residue after the production of rose essential oil as a raw material, and is prepared through the steps of extract extraction, organic solvent extraction, MCI decolorization, silica gel column chromatography and high performance liquid chromatography separation steps, specifically :

[0050] A. Extraction extraction: The waste residue powder after the production of rose essential oil is ultrasonically extracted with a solvent for 2 to 5 times. The quality of the extraction solvent used each time is 2 to 6 times the quality of the waste residue powder. Each extraction time is 30 to 60 minutes. The extracts are combined and filtered, the filtrate is concentrated under reduced pressure until a precipitate just separates out, and the mixture is allowed to stand for 20-60 minutes to remove the precipitate, and then the obtained filtrate is concentrated under reduced pressure to extract a;

[0051] B...

Embodiment 1

[0062] The waste residue sample from the production of rose essential oil comes from Yuxi, Yunnan, and the species is Damascus rose.

[0063] A. Extraction extraction: The waste residue powder after the production of rose essential oil is ultrasonically extracted twice with a solvent. The quality of the extraction solvent used each time is twice the quality of the waste residue powder. Each extraction time is 30 minutes. The extracts are combined and filtered. The filtrate was concentrated under reduced pressure until the precipitate just precipitated, and it was allowed to stand for 20 minutes to remove the precipitate, and then the obtained filtrate was concentrated under reduced pressure to extract a;

[0064] B. Organic solvent extraction: add water of 1 times the weight of extract a to extract a, and then extract 3 times with an organic solvent, each time the volume of organic solvent used is the same as the volume of water, and the organic solvent extraction phases are combine...

Embodiment 2

[0070] The waste residue sample from the production of rose essential oil comes from Yuxi, Yunnan, and the species is Damascus rose.

[0071] A. Extraction extraction: The waste residue powder after the production of rose essential oil is ultrasonically extracted 5 times with a solvent. The quality of the extraction solvent used each time is 6 times the quality of the waste residue powder. Each extraction time is 60 minutes. The extracts are combined and filtered. The filtrate was concentrated under reduced pressure until the precipitate just precipitated, and it was allowed to stand for 60 minutes to filter out the precipitate, and then the obtained filtrate was concentrated under reduced pressure to extract a;

[0072] B. Organic solvent extraction: add water twice the weight of extract a to extract a, and then extract 5 times with an organic solvent, each time the volume of organic solvent used is the same as the volume of water, and the organic solvent extraction phases are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com