Method for producing cutting oil and mould release agent by using waste engine oil

A release agent and cutting oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of low resource recovery rate, high economic cost, low economic value, etc., and achieve low technical level and low equipment investment requirements. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

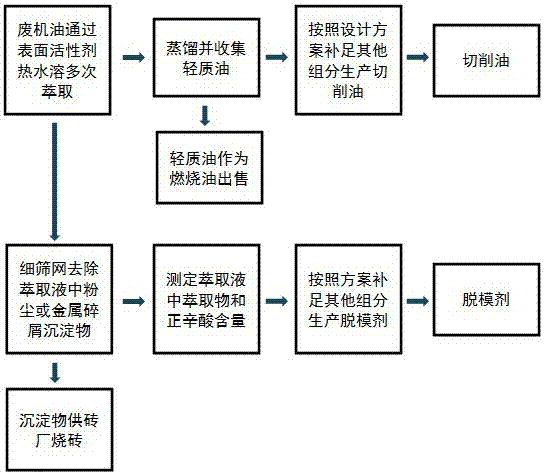

Image

Examples

Embodiment 1

[0019] (1) Dissolve n-octanoic acid in hot water to prepare n-octanoic acid solution with a mass concentration of 10%, raise the temperature to 80°C and stir well, add waste engine oil with 3 times the mass of n-octanoic acid under stirring state and heat up to 80°C and stir for 30min , then keep the temperature for 5 hours, separate the liquid, repeat the above steps to extract the supernatant for the second time and the third time, wash with hot water after each extraction, and then combine all the extracts and washings Filter off the residue to obtain the release agent precursor, control the water content in the release agent precursor to 40% by controlling the amount of hot water used in the washing process, and collect the upper oily solution after the third extraction and separation as the cutting oil precursor stand-by;

[0020] (2) Add the release agent precursor solution, emulsifier and wetting and dispersing agent obtained in step (1) into the reactor, and the weight...

Embodiment 2

[0023] (1) Dissolve n-octanoic acid in hot water to prepare n-octanoic acid solution with a mass concentration of 15%, raise the temperature to 80°C and stir well, add waste engine oil with 4 times the mass of n-octanoic acid under stirring state and heat up to 80°C and stir for 30min , and then keep it for 6 hours, separate the liquid, repeat the above steps to extract the supernatant for the second time and the third time, wash with hot water after each extraction, and then combine all the extracts and washings Filter off the residue to obtain the release agent precursor, control the water content in the release agent precursor to 50% by controlling the amount of hot water used in the washing process, and collect the upper oily solution after the third extraction and separation as the cutting oil precursor stand-by;

[0024] (2) Add the release agent precursor solution, emulsifier and wetting and dispersing agent obtained in step (1) into the reactor, wherein the weight perc...

Embodiment 3

[0027](1) Dissolve n-octanoic acid in hot water to prepare n-octanoic acid solution with a mass concentration of 20%, raise the temperature to 80°C and stir well, add waste engine oil with 5 times the mass of n-octanoic acid under stirring state and heat up to 80°C and stir for 30min , and then keep it for 6 hours, separate the liquid, repeat the above steps to extract the supernatant for the second time and the third time, wash with hot water after each extraction, and then combine all the extracts and washings Filter off the residue to obtain the release agent precursor, control the water content in the release agent precursor to 60% by controlling the amount of hot water used in the washing process, and collect the upper oily solution after the third extraction and separation as the cutting oil precursor stand-by;

[0028] (2) Add the release agent precursor solution, emulsifier and wetting and dispersing agent obtained in step (1) into the reaction kettle, wherein the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com