Preparation technology of beef jerky

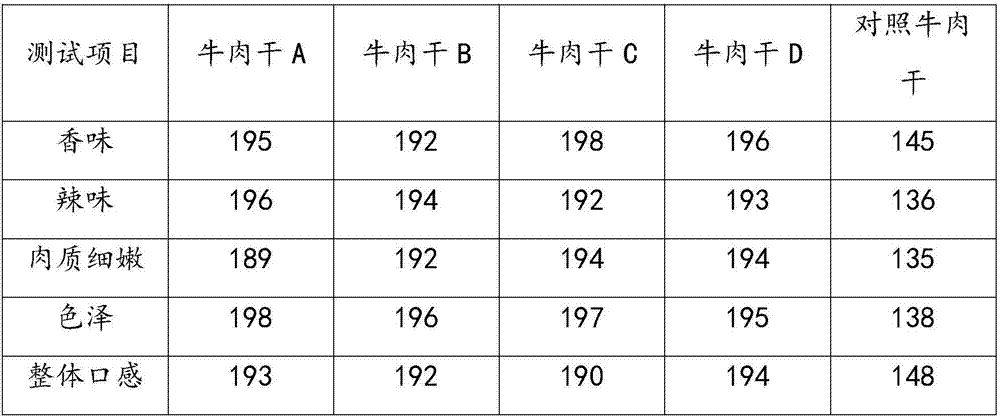

A preparation process, the technology of beef jerky, which is applied in the field of food processing, can solve the problems of rough taste of beef jerky and cumbersome production steps, etc., and achieve the effect of benefiting human health, tender meat, and ruddy color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. Pretreatment

[0030] Wash 4.1g of beef, and remove the fat sarcolemma, tendons and floating skin on the beef;

[0031] B. Pickled

[0032] Add a marinade to the beef pretreated in step A to marinate. The marinade time is 2 hours, and the marinade temperature is controlled at 55° C.; the marinade is composed of the following raw materials in parts by weight: 0.2 g of papain, 2 g of monosodium glutamate , calcium chloride 1g, white sugar 5g, D-sorbitol 1g, salt 3g, sodium nitrite 0.015g, sodium iso-Vc 0.04g;

[0033] C, sliced, stewed

[0034] Add water and seasonings to the thin slices of beef obtained by marinating in step B and cut the thin slices of beef with a thickness of 3mm to stew; the mass ratio of water and seasonings is 30:1, and the seasonings are composed of the following raw materials in parts by weight: 2g ginger, 0.3g fennel, 0.3g star anise, 0.4g cinnamon, 0.01g pepper, 0.02g licorice, 0.04g clove, 0.3g nutmeg, 0.03g yellow mustard, 0.1g Wujiapi, ...

Embodiment 2

[0038] A. Pretreatment

[0039] Wash 4.8g of beef, and remove the fat sarcolemma, tendons and floating skin on the beef;

[0040] B. Pickled

[0041] Add marinade to the beef pretreated in step A to marinate. The marinade time is 3 hours, and the marinade temperature is controlled at 58° C.; the marinade consists of the following raw materials in parts by weight: 0.3 g of papain, 3 g of monosodium glutamate, chlorine Calcium 2g, white sugar 6g, D-sorbitol 2g, salt 5g, sodium nitrite 0.02g, sodium iso-Vc 0.06g;

[0042] C, sliced, stewed

[0043] Cut the beef marinated in step B into thin slices. The thickness of the beef slices is 4mm, and then add water and seasonings to stew; the mass ratio of water and seasonings is 32:1, and the seasonings are made of the following raw materials in parts by weight Composition: 1.5g ginger, 0.4g fennel, 0.4g star anise, 0.5g cinnamon, 0.03g prickly ash, 0.04g licorice, 0.05g clove, 0.4g nutmeg, 0.04g yellow mustard seed, 0.2g bark of Wuj...

Embodiment 3

[0047] A. Pretreatment

[0048] Wash 5.5g of beef, and remove the fat sarcolemma, tendons and floating skin on the beef;

[0049] B. Pickled

[0050] The beef pretreated in step A is added to marinade for marinating, the marinating time is 5 hours, and the curing temperature is controlled at 60° C.; the marinade is composed of the following raw materials in parts by weight: 0.5 g of papain, 5 g of monosodium glutamate, chlorine Calcium 3g, white sugar 8g, D-sorbitol 3g, salt 8g, sodium nitrite 0.03g, sodium iso-Vc 0.08g;

[0051] C, sliced, stewed

[0052] Cut the beef marinated in step B into thin slices, the thickness of the thin beef slices is 5mm, then add water and seasonings to stew; the mass ratio of water and seasonings is 35:1, and the seasonings are composed of the following raw materials in parts by weight : 2g ginger, 0.5g fennel, 0.5g star anise, 0.6g cinnamon, 0.05g Chinese prickly ash, 0.06g licorice, 0.06g clove, 0.5g nutmeg, 0.06g yellow mustard seed, 0.3g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com