Preparation method of calcium phosphate/gelatin compound material nano particles and application thereof

A composite material and nanoparticle technology, applied in the field of bioengineering, can solve the problems of large specific surface area and poor mechanical properties of colloidal composite materials, and achieve the effects of stable reaction conditions, biocompatibility, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

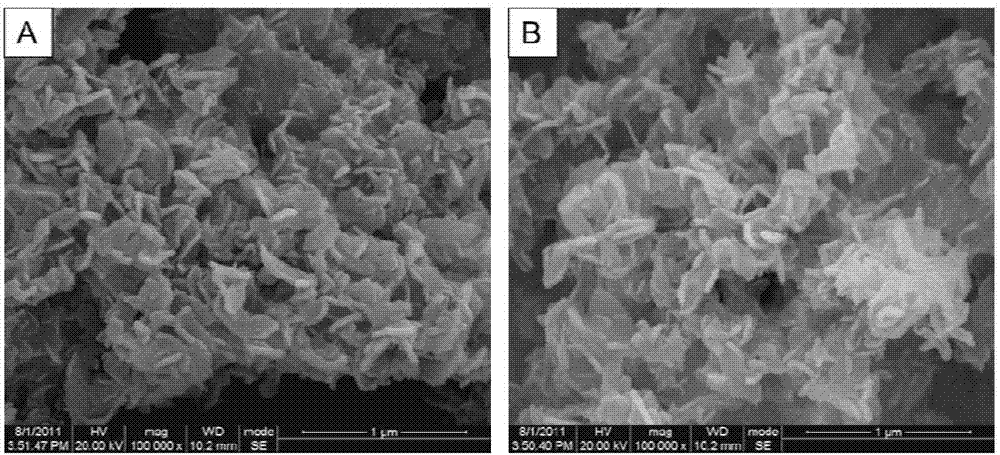

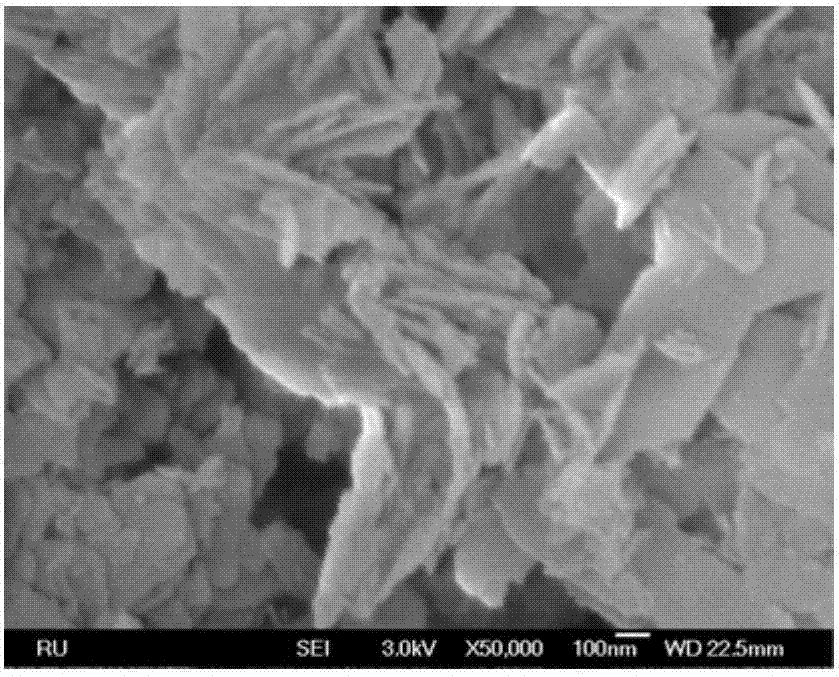

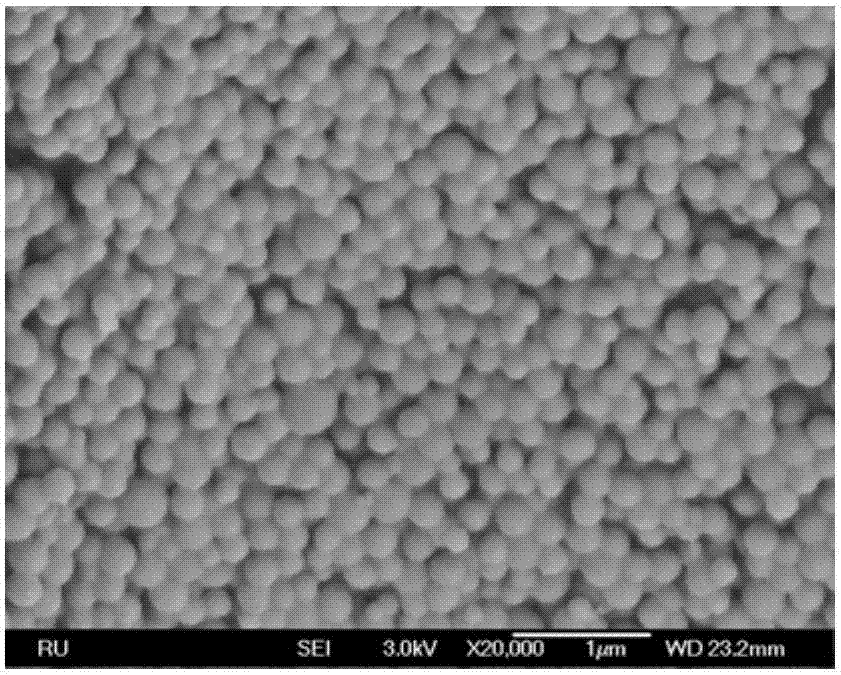

Image

Examples

Embodiment 1

[0065] Calcium phosphate / gelatin composite nanoparticles were prepared as follows:

[0066] (1) Dissolve 1.25g of gelatin in 25mL of deionized water, and keep heating to 40°C to obtain a clear and transparent gelatin aqueous solution; dissolve 0.138g of disodium hydrogen phosphate in the gelatin aqueous solution, and continue stirring and heating at 300rpm At 40°C, add NaOH solution dropwise to adjust the pH value of the solution to 10 to obtain disodium hydrogen phosphate-gelatin aqueous solution;

[0067] (2) Dissolve 0.106g of calcium chloride in 75mL of absolute ethanol, and after complete dissolution, add the calcium chloride ethanol solution drop by drop into the above-mentioned disodium hydrogen phosphate gelatin aqueous solution, and keep heating at 40°C and continue stirring (1000rpm), along with dropping process carries out, forms the suspension of calcium phosphate / gelatin composite material nanoparticle gradually, theoretical calculation, the calcium / phosphorus rat...

Embodiment 2

[0090] Calcium phosphate / gelatin composite nanoparticles were prepared as follows:

[0091] (1) Dissolve 1.25g of gelatin in 25mL of deionized water at 30°C, 40°C and 60°C respectively, and keep the temperature to obtain a clear and transparent gelatin aqueous solution; dissolve 0.138g of disodium hydrogen phosphate in the gelatin aqueous solution In, and keep stirring (300rpm) and heating, the pH value of above-mentioned aqueous solution is adjusted to 10 by adding NaOH solution dropwise, obtains the gelatin aqueous solution of disodium hydrogen phosphate;

[0092] (2) Dissolve 0.106g of calcium chloride in 75mL of absolute ethanol, and after the complete dissolution, add the calcium chloride ethanol solution drop by drop into the above-mentioned disodium hydrogen phosphate gelatin aqueous solution, and respectively 30 ℃, 40 ℃ and 60°C and continuous stirring (500-1000rpm), as the dropping process proceeds, a suspension of calcium phosphate / gelatin composite nanoparticles is ...

Embodiment 3

[0099] Calcium phosphate / gelatin composite nanoparticles were prepared as follows:

[0100] (1) Dissolve 1.25g of gelatin in 25mL of deionized water, and keep the temperature to obtain a clear and transparent gelatin aqueous solution; dissolve 0.138g of disodium hydrogen phosphate in the gelatin aqueous solution, and keep stirring (300rpm) and heating, by dropping Add NaOH solution to adjust the pH value of the above aqueous solution to 10 to obtain a gelatin aqueous solution of disodium hydrogen phosphate;

[0101] (2) Dissolve 0.106g of calcium chloride in dehydrated alcohol of 50, 75, 125 and 225mL respectively, and add the calcium chloride ethanol solution dropwise to the hydrogen phosphate obtained in step (1) after the complete dissolution In the gelatin aqueous solution of disodium, keep stirring (500-1000rpm) under the heating condition of 40 ℃, along with the dropwise addition process, gradually form the suspension of calcium phosphate / gelatin composite nanoparticle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com