Manufacturing method of mems chip packaging structure capable of stress release by inversion assembly

A chip packaging structure and manufacturing method technology, applied in the direction of assembling microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of increasing the complexity and cost of processing, chip deformation, increasing the total thickness of the device, etc., to increase processing. Number and complexity of steps, effect of increasing packaging cost, reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

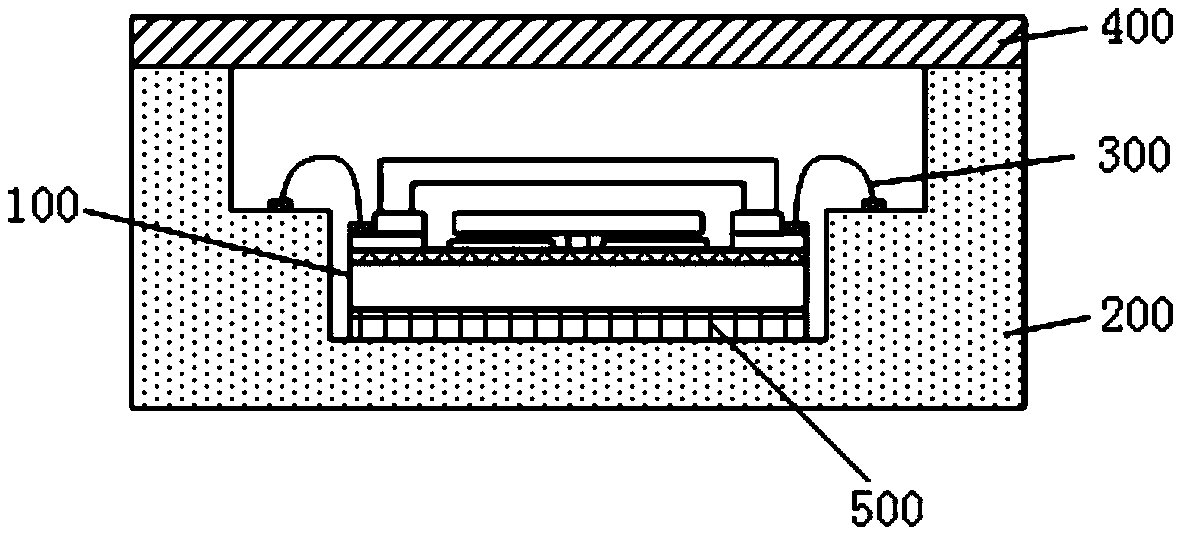

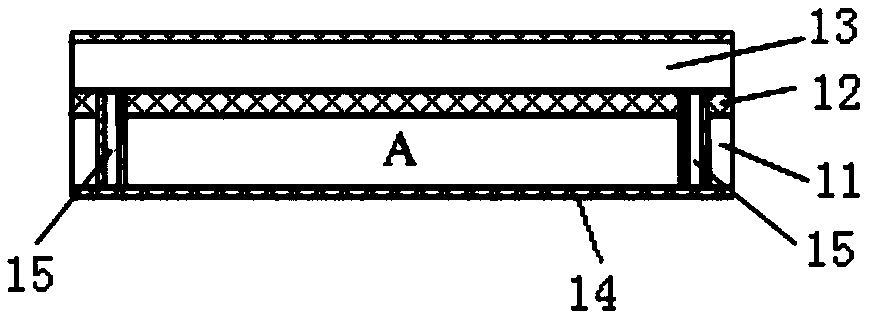

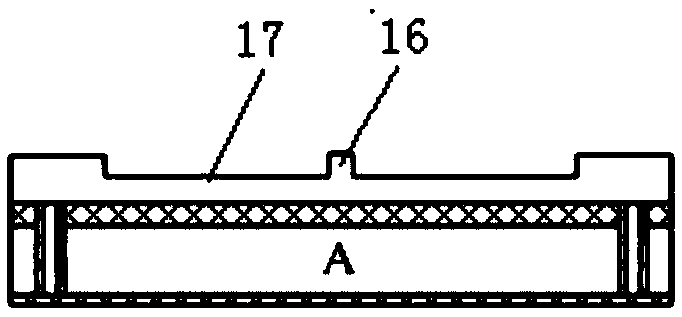

[0046] Traditional variable-pitch MEMS capacitive sensors such as figure 1 shown. The lower electrode of the MEMS capacitive sensor is directly fixed on the silicon dioxide isolation layer, and the silicon dioxide isolation layer is fixed on the silicon substrate. The upper electrode of the MEMS capacitive sensor (that is, the MEMS sensitive structural mass) is suspended on the lower electrode through the support of the central anchor point structure. The upper electrode and the lower electrode form a capacitance relative to each other. When there is an external sensitive quantity input, the capacitance value formed by the upper electrode and the lower electrode changes, and the detection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com