Polyamide composite membrane high-flux modification method based on ether free radicals

A technology of polyamide and free radicals, which is applied in the field of modification to improve the water flux and anti-pollution performance of polyamide composite reverse osmosis membranes and nanofiltration membranes, and can solve the problem of limited improvement in the properties of polyamide composite membranes and insufficient graft layers Uniformity and density, limited number of active groups, etc., to achieve the effect of improving water flux, not easy to pollute, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

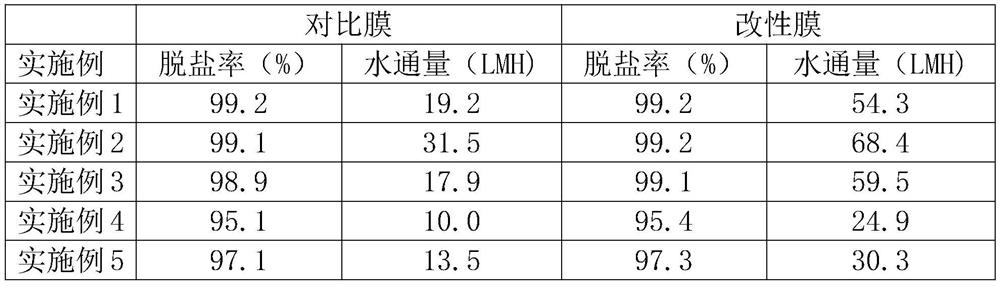

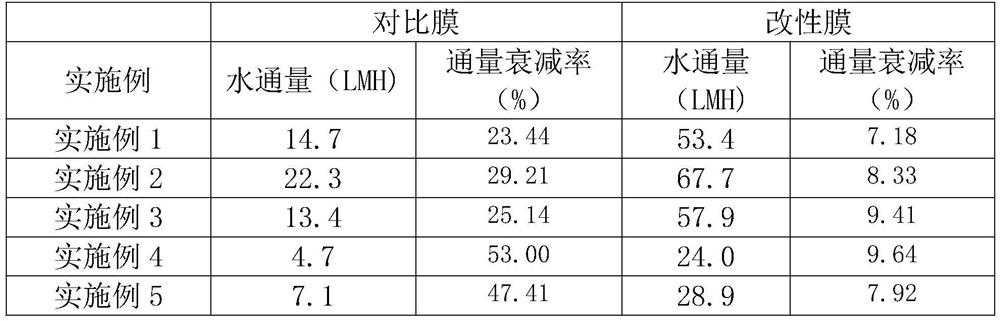

[0024] Select the polyamide composite reverse osmosis membrane from Dow Filmtec Company in the United States, immerse it in the modification solution, and modify it at 50°C for 1h. The modification solution includes: 5mmol / L sodium persulfate, 2mol / L methyl ether aqueous solution. After the modification solution was preheated to 50°C, the polyamide composite membrane was added, and the membrane was removed after modification for 1 hour, washed repeatedly with a large amount of deionized water, and then tested.

[0025] The membrane that was not treated with the modifying solution was the comparative membrane.

[0026] The test conditions of water flux and desalination rate are: operating pressure 16bar, flow rate 4LPM, pre-pressing the modified membrane and the comparison membrane with ultra-pure water at 25°C for 8h to stabilize the membrane performance, adjust the operating pressure to 14bar, and measure the modified membrane and the water flux of the comparison membrane. ...

Embodiment 2

[0028] Select the polyamide composite reverse osmosis membrane from Zhongke Ruiyang Membrane Technology (Beijing) Co., Ltd., immerse it in the modification solution, and modify it at 70°C for 0.5h. The modification solution includes: 2mmol / L potassium hydrogen persulfate compound salt, 2mol / L methyl ether aqueous solution. After the modification solution was preheated to 70°C, the polyamide composite membrane was added, and the membrane was taken out after modification for 0.5h, washed repeatedly with a large amount of deionized water, and then tested.

[0029] The membrane that was not treated with the modifying solution was the comparative membrane.

[0030] The test conditions of water flux and salt rejection rate are as described in Example 1.

Embodiment 3

[0032] Select the polyamide composite reverse osmosis membrane self-developed by the inventor, immerse it in the modified solution, at a wavelength of 254nm, 800mJ / cm 2 Under the condition of luminous flux, UV irradiation modification was carried out for 1h. The modification solution includes: 1 mmol / L potassium hydrogen persulfate compound salt, 5 mol / L 1,4-dioxane aqueous solution. Turn on the UV lamp for 10 minutes and wait for the light to stabilize, then add polyamide composite membrane, take out the membrane after modification for 1 hour, wash it repeatedly with a large amount of deionized water, and then test it.

[0033] The membrane that was not treated with the modifying solution was the comparative membrane.

[0034] The test conditions of water flux and salt rejection rate are as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com