A deep denitrification and turbidity reduction reactor and its application

A deep denitrification and reactor technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, multi-stage water treatment, etc., can solve the problems of long residence time and low removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

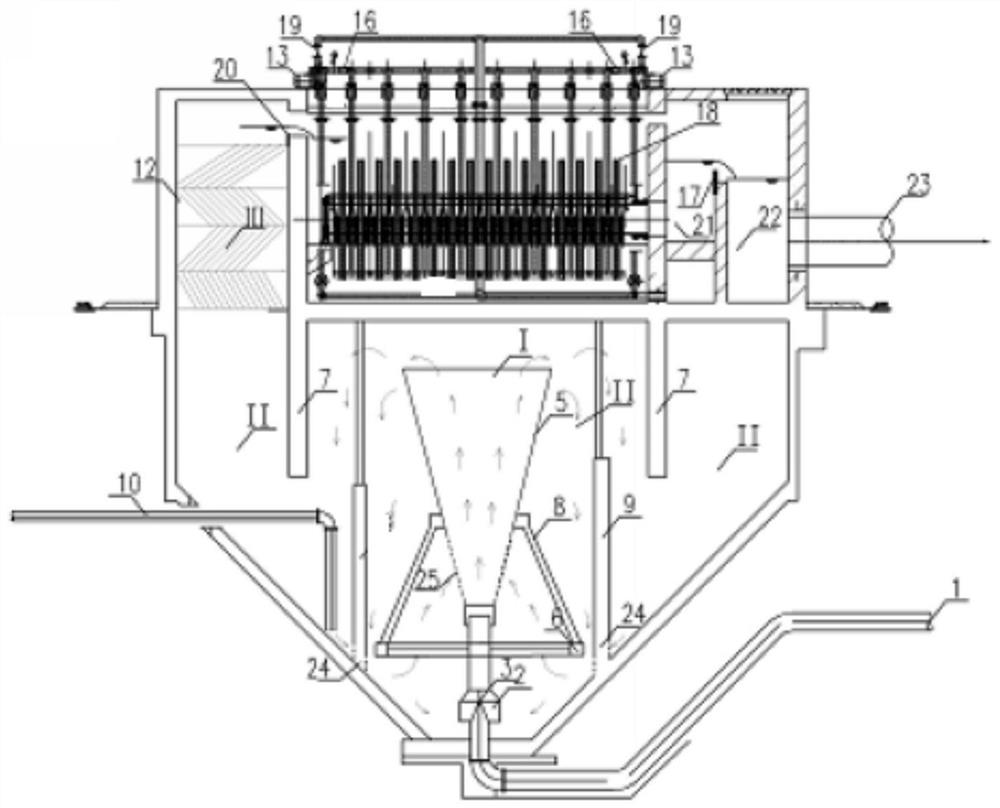

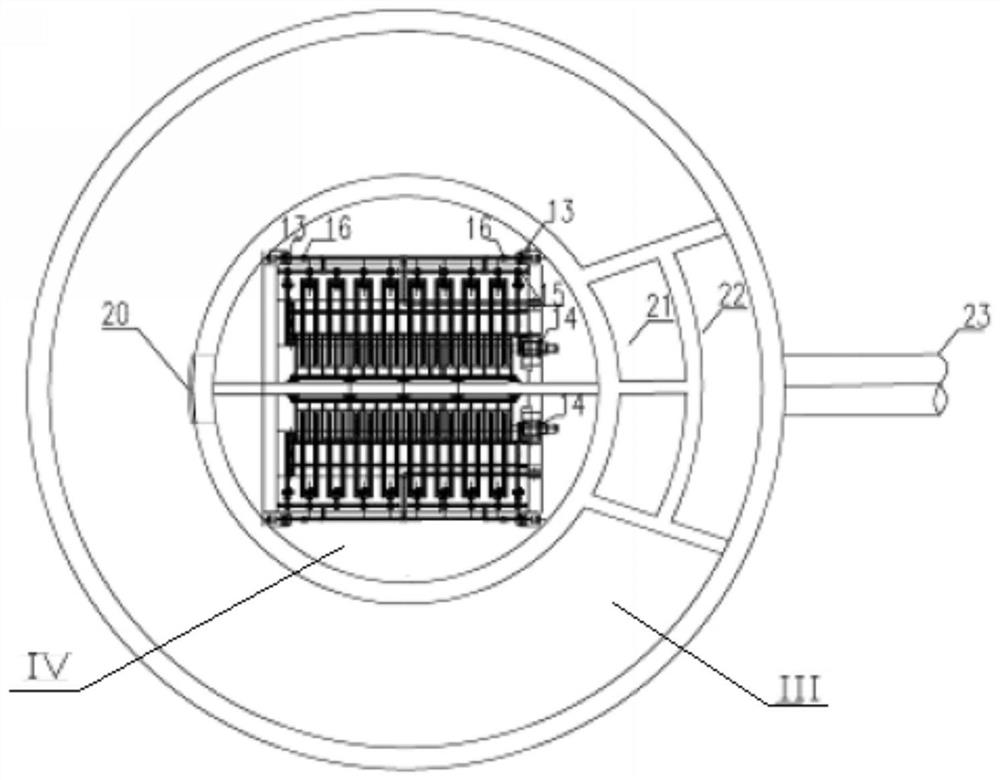

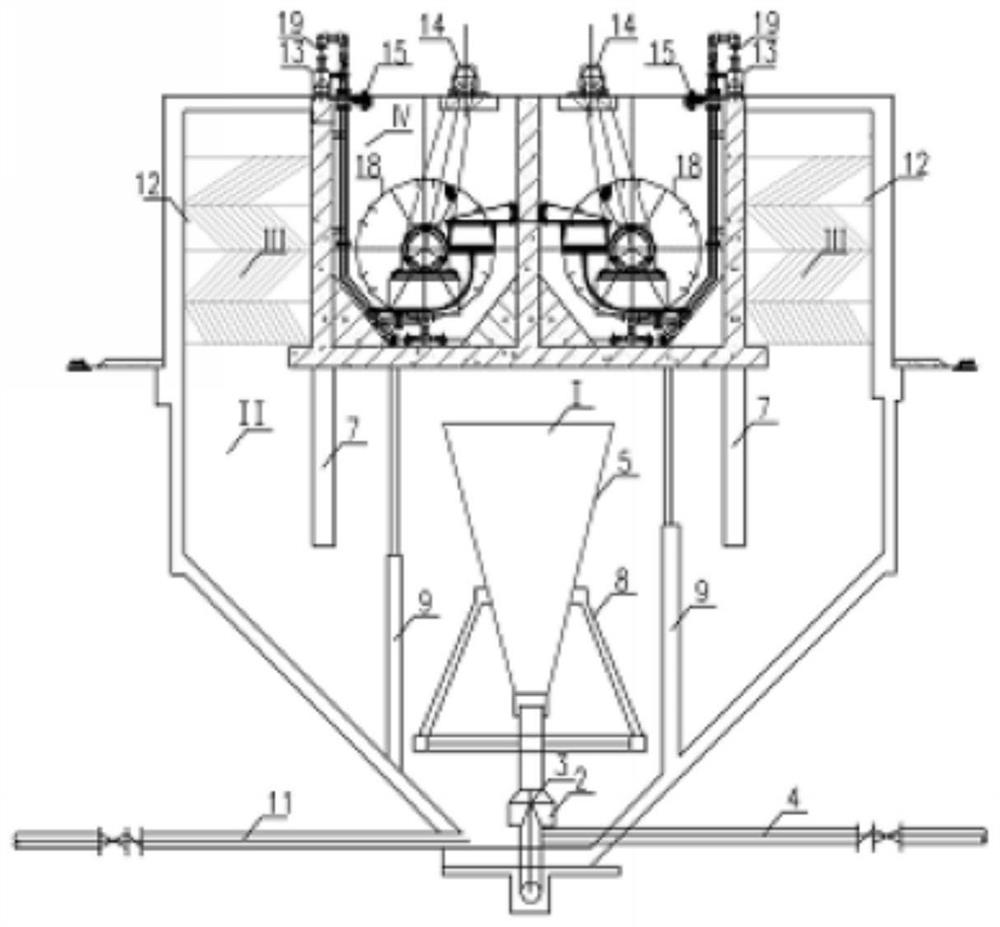

[0043] The effluent from the secondary treatment of a sewage plant directly enters the equipment of the present invention, and successively passes through the chemical mixing flocculation zone I, the deep denitrification zone II, the inclined plate sedimentation zone III and the rotary filter zone IV.

[0044] In the agent mixing and flocculation zone I, the speed of the nozzle 3 of the tapered throat pipe is v=4.05m / s, the speed of the waiting pipe is v=2.65m / s, and the exit speed of the inverted conical expanding barrel 5 is v=95mm / s.

[0045] Add 14% xanthan gum, 3.85% polyaluminum chloride, 1.2% kaolin and 0.65% CaCl according to the mass ratio of the original preparation to the conventional denitrification bioflocculant provided by the Heilongjiang Provincial Key Laboratory of Environmental Biotechnology 2 , to make a special biological denitrification flocculant, increase the flocculation effect, meet the requirements of denitrification carbon source, and improve the deni...

Embodiment 2

[0051] The secondary treatment effluent (temperature 12° C.) of a certain sewage plant in the north directly enters the equipment of the present invention. In the medicament mixing and flocculation zone I, the speed of the nozzle 3 of the shrinking throat pipe v=3.95m / s, and the speed of the waiting pipe v=2.55m / s, the outlet velocity v=85mm / s of inverted conical expanding barrel 5.

[0052] Add 11% xanthan gum, 3.5% polyaluminum chloride, 1.1% kaolin and 0.55% CaCl according to the mass ratio of the original preparation to the conventional denitrification bioflocculant provided by the Heilongjiang Provincial Key Laboratory of Environmental Biotechnology 2 , to make a special biological denitrification flocculant, increase the flocculation effect, meet the requirements of denitrification carbon source, and improve the denitrification efficiency.

[0053] The length of the single-layer inclined plate 12 in the inclined plate precipitation zone III is 0.4m; the inclination angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com