Super-high toughness cement base composite material and preparation method thereof

A composite material and ultra-high toughness technology, applied in the field of materials science, can solve the problems of affecting tensile performance, slurry viscosity and poor water retention, and achieve improved tensile performance, high tensile strain, improved viscosity and The effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

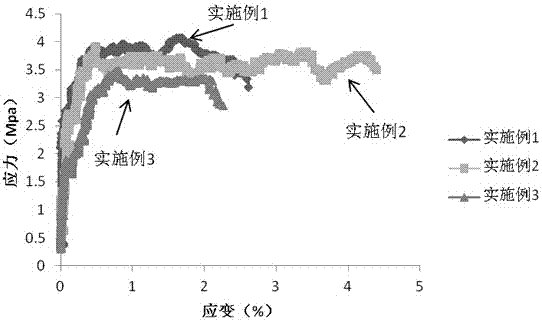

Examples

Embodiment 1

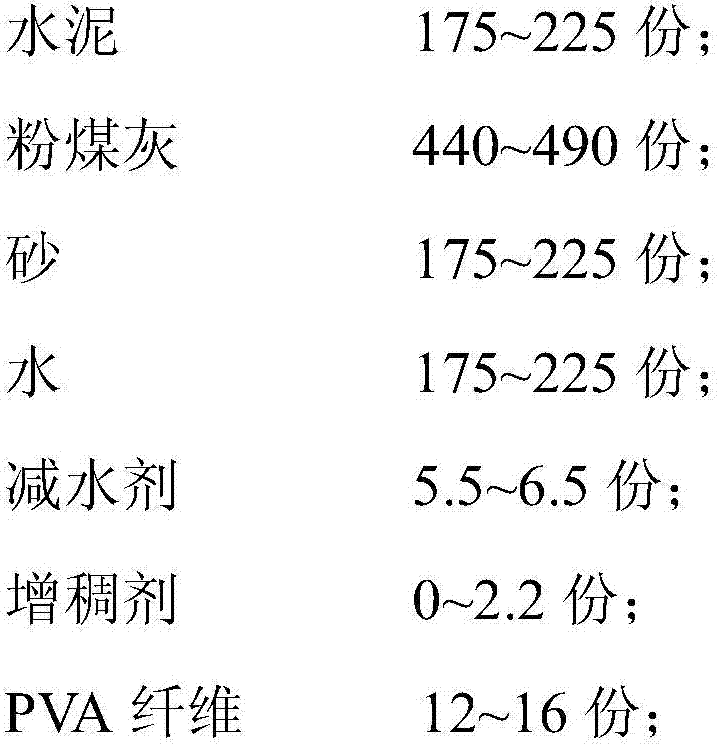

[0027] An ultra-high toughness cement-based composite material, calculated in parts by mass, its raw material composition and content are as follows:

[0028]

[0029]

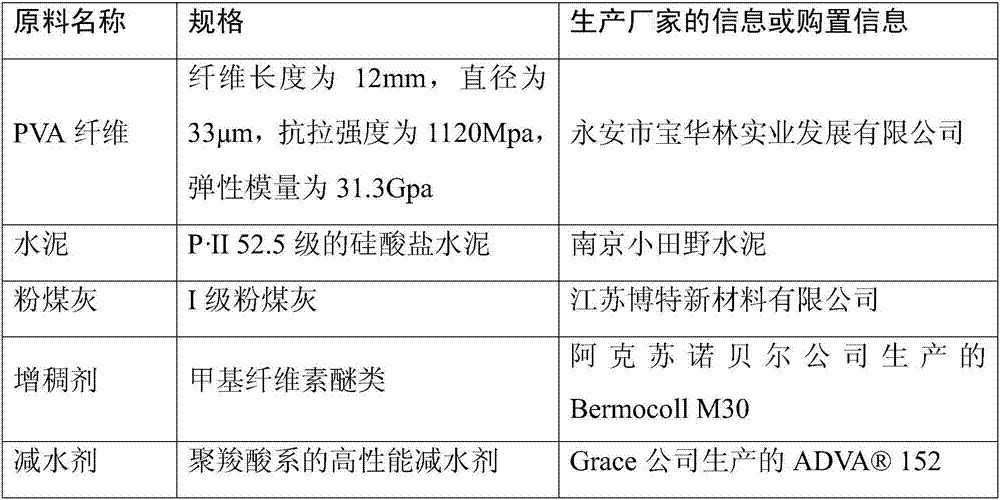

[0030] Described cement is the portland cement of P·II 52.5;

[0031] Described fly ash is Class I fly ash;

[0032] The sand is 30-100 mesh quartz sand;

[0033] The described water reducer is a high-performance water reducer of polycarboxylic acid series, specifically produced by Grace Company 152 superplasticizer;

[0034] The thickener is methyl cellulose ether, specifically BermocollM30 produced by Akzo Nobel;

[0035] The PVA fiber is produced by Baohualin Industrial Development Co., Ltd. in Yongan City. Its fiber length is 12mm, diameter is 33μm, tensile strength is 1120Mpa, and elastic modulus is 31.3Gpa.

[0036] The preparation method of the above-mentioned a kind of ultra-high toughness cement-based composite material, the specific steps are as follows:

[0037] First, add cement, fly as...

Embodiment 2

[0041] An ultra-high toughness cement-based composite material, calculated in parts by mass, its raw material composition and content are as follows:

[0042]

[0043]

[0044] Described cement is the portland cement of P·II 52.5 grade;

[0045] Described fly ash is Class I fly ash;

[0046] The sand is 30-100 mesh quartz sand;

[0047] The described water reducer is a high-performance water reducer of polycarboxylic acid series, specifically produced by Grace Company 152 superplasticizer;

[0048] The thickener is methyl cellulose ether, specifically BermocollM30 produced by Akzo Nobel;

[0049] The PVA fiber is produced by Baohualin Industrial Development Co., Ltd. in Yongan City. Its fiber length is 12mm, diameter is 33μm, tensile strength is 1120Mpa, and elastic modulus is 31.3Gpa.

[0050] The preparation method of the above-mentioned ultra-high toughness cement-based composite material mixed with a thickener, the specific steps are as follows:

[0051] First,...

Embodiment 3

[0055] An ultra-high toughness cement-based composite material, calculated in parts by mass, its raw material composition and content are as follows:

[0056]

[0057]

[0058] Described cement is the portland cement of P·II 52.5 grade;

[0059] Described fly ash is Class I fly ash;

[0060] The sand is 30-100 mesh quartz sand;

[0061]The described water reducer is a high-performance water reducer of polycarboxylic acid series, specifically produced by Grace Company 152 superplasticizer;

[0062] The thickener is methyl cellulose ether, specifically BermocollM30 produced by Akzo Nobel;

[0063] The PVA fiber is produced by Baohualin Industrial Development Co., Ltd. in Yongan City. Its fiber length is 12mm, diameter is 33μm, tensile strength is 1120Mpa, and elastic modulus is 31.3Gpa.

[0064] The preparation method of the above-mentioned a kind of ultra-high toughness cement-based composite material, the specific steps are as follows:

[0065] First, add cement, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com