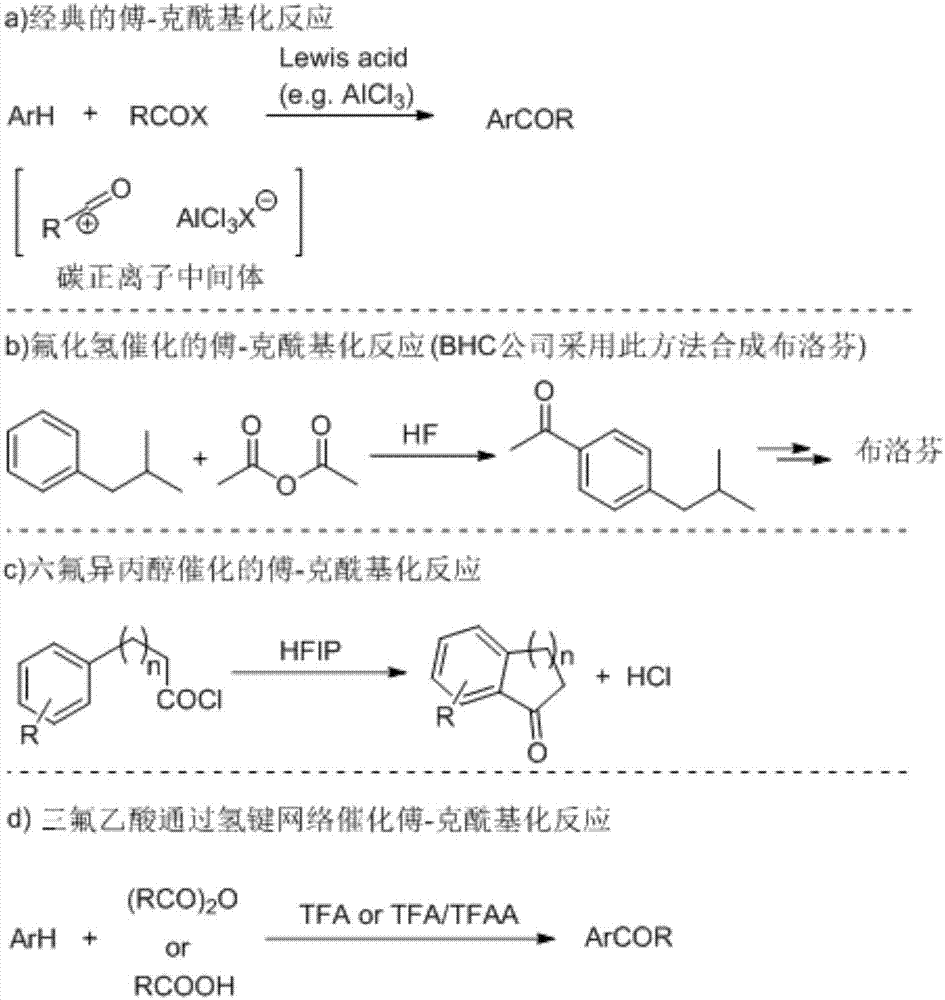

Friedel-Crafts acylation reaction catalyzed trifluoroacetic acid

A technology of trifluoroacetic acid and trifluoroacetic anhydride, which is applied in the field of Friedel-Crafts acylation reaction, can solve the problems that catalysts cannot be recycled well, environmental pollution, a large amount of aluminum salt waste liquid, etc., and achieves good application prospects and economy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] By screening the reaction conditions:

[0019] entry

equiv of 2a

Yield b / %

1

2

TFA (1mL)

100

2

2

50:50 TFA / DCM

69

3

2

80:20 TFA / DCM

95

4

2

50:50 TFA / HFIP

14

5

2

80:20 TFA / HFIP

44

6

2

TFA (0.5mL)

95

7

2

TFA (0.8mL)

100(95 c )

8

1.2

TFA (0.8mL)

84

9

1.5

TFA (0.8mL)

96

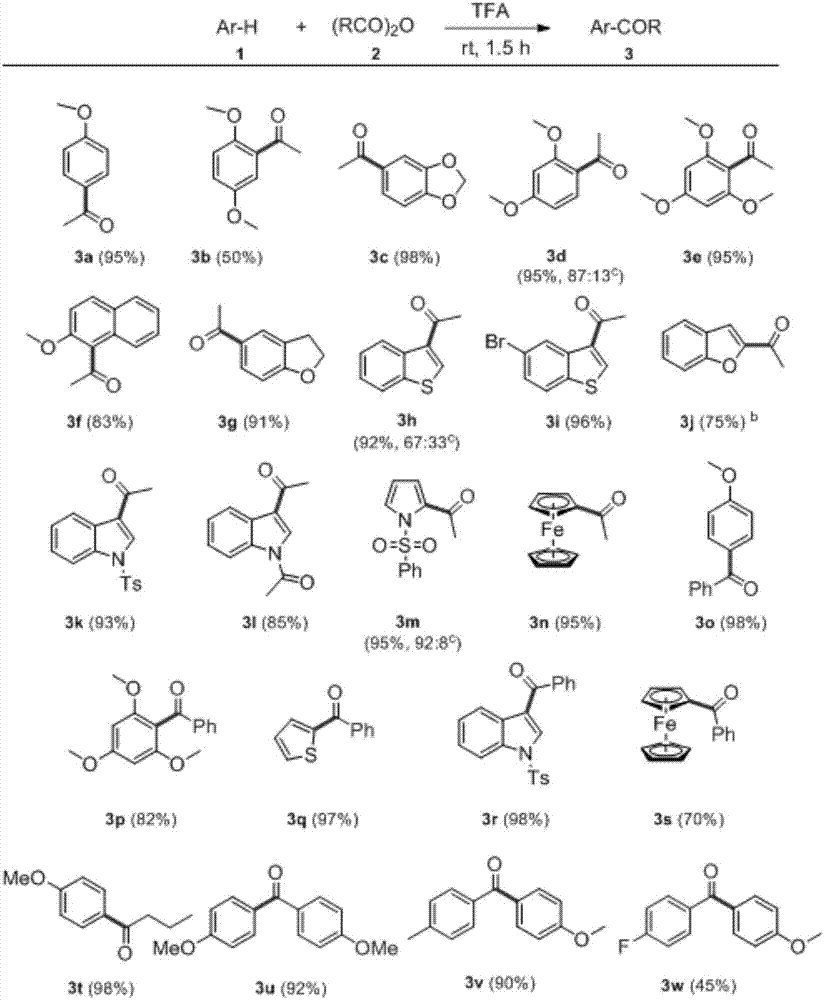

[0020] The best reaction conditions were obtained, that is, at room temperature, anisole (0.75mmol) and acetic anhydride (1.5mmol) were reacted in trifluoroacetic acid (0.8mL) for 1.5h to obtain the target product with a conversion rate of 100%. The applicable range and conversion rate of other substrates are as follows: figure 2 shown.

[0021]

Embodiment 2

[0023] By screening the reaction conditions:

[0024] entry

equiv of 2a

Yield b / %

1

1

TFA (1mL)

53

2

1.5

TFA (1mL)

62

3

2

TFA (1mL)

50

4

3

TFA (1mL)

62

5

1.5

TFA (2mL)

78(65 c )

6

1.5

TFA (3mL)

71

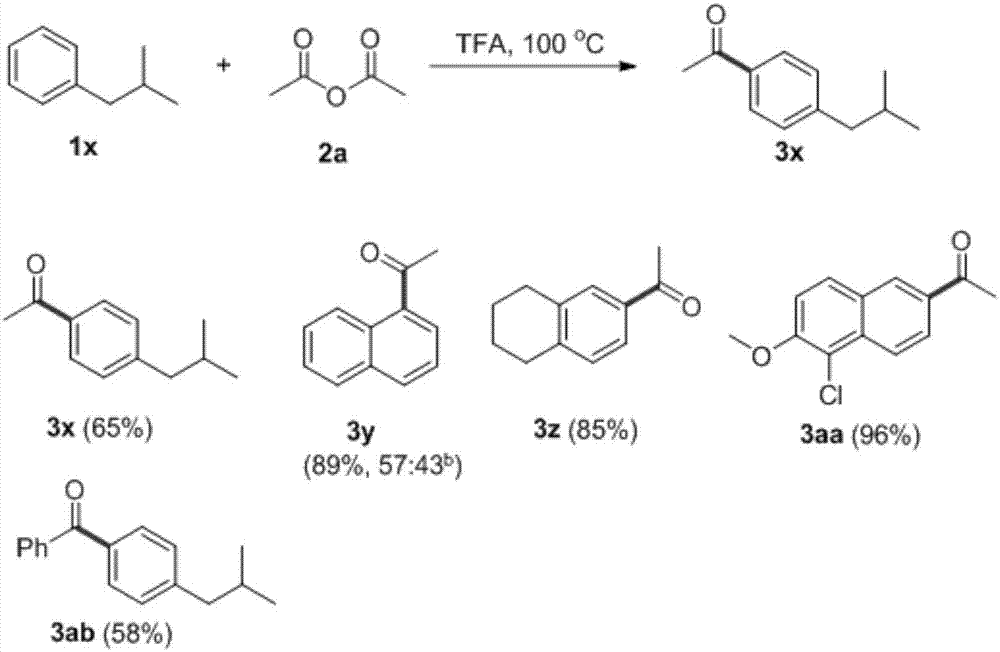

[0025] The optimal reaction conditions were obtained, that is, at 100°C, isobutylbenzene (0.75mmol) and acetic anhydride (1.125mmol) were reacted in trifluoroacetic acid (2mL) for 56h to obtain the target product with a conversion rate of 78%. The applicable range and conversion rate of other substrates are as follows: image 3 shown.

[0026]

Embodiment 3

[0028] By screening the reaction conditions:

[0029] entry

equiv of 1a

Yield b / %

1

1

Trifluoroacetate

48

2

1.2

Trifluoroacetate

95

3

1.5

Trifluoroacetate

98

4

2

Trifluoroacetate

98

[0030] The best reaction conditions were obtained, that is, at room temperature, anisole (1.125mmol), benzoic acid (0.75mmol), and trifluoroacetic anhydride (1.5mmol) were reacted in trifluoroacetic acid (0.8mL) for 12h to obtain the target Product, 98% conversion. The applicable range and conversion rate of other substrates are as follows: Figure 4 shown.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com