Ethylene polymerization method and polyethylene

A technology of ethylene polymerization and polymerization reaction, applied in the field of polyethylene, which can solve the problems of poor thermal stability and hydrothermal stability, collapse of pore walls, low ethylene polymerization activity, etc., and achieve stable mesopore structure, not easily broken, and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In a preferred case, the preparation method of the catalyst may include: in the presence of an inert gas, impregnating the carrier in a mother liquor containing magnesium salt and / or titanium salt, and then successively filtering and drying; wherein, the carrier The spherical composite material provided by the present invention.

[0025] In the present invention, the impregnating conditions may include: a temperature of 25-100° C., and a time of 0.1-5 hours; preferably, the impregnating conditions include: a temperature of 40-60° C., and a time of 1-3 hours.

[0026] In the present invention, the amount of the magnesium salt and the titanium salt is not particularly limited, and preferably, the amount of the carrier, the magnesium salt, and the titanium salt is such that in the prepared supported polyethylene catalyst, the Based on the total weight of the catalyst, the content of the carrier is 90-99% by weight, and the sum of the contents of the magnesium salt and tita...

Embodiment 1

[0083] This embodiment is used to illustrate the ethylene polymerization method provided by the present invention.

[0084] (1) Preparation of spherical composite materials

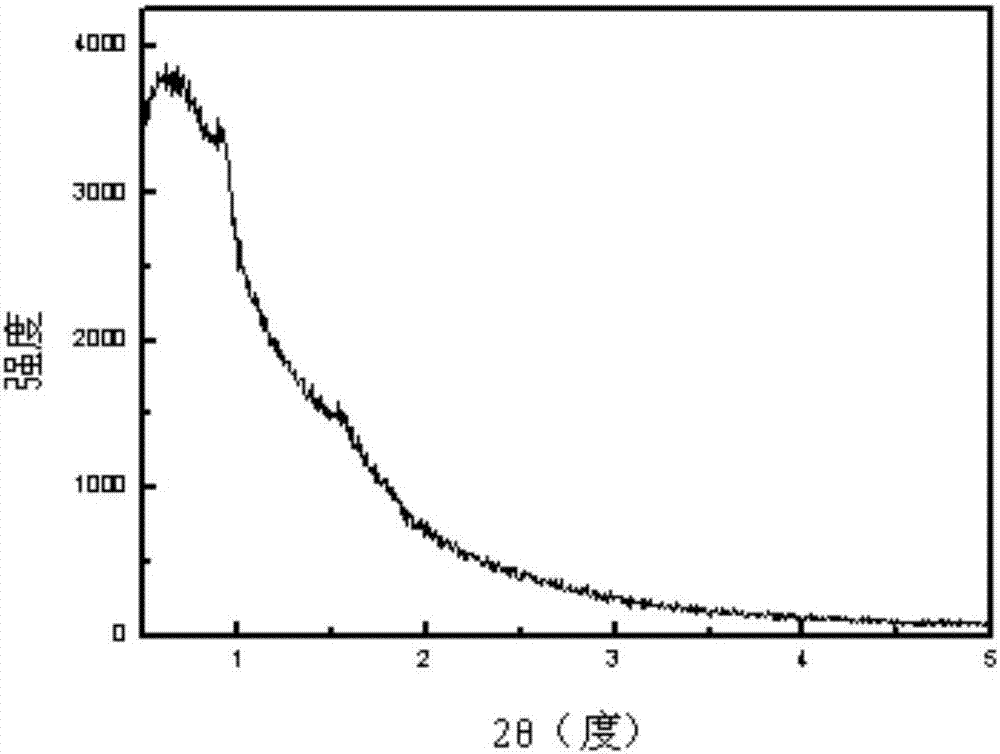

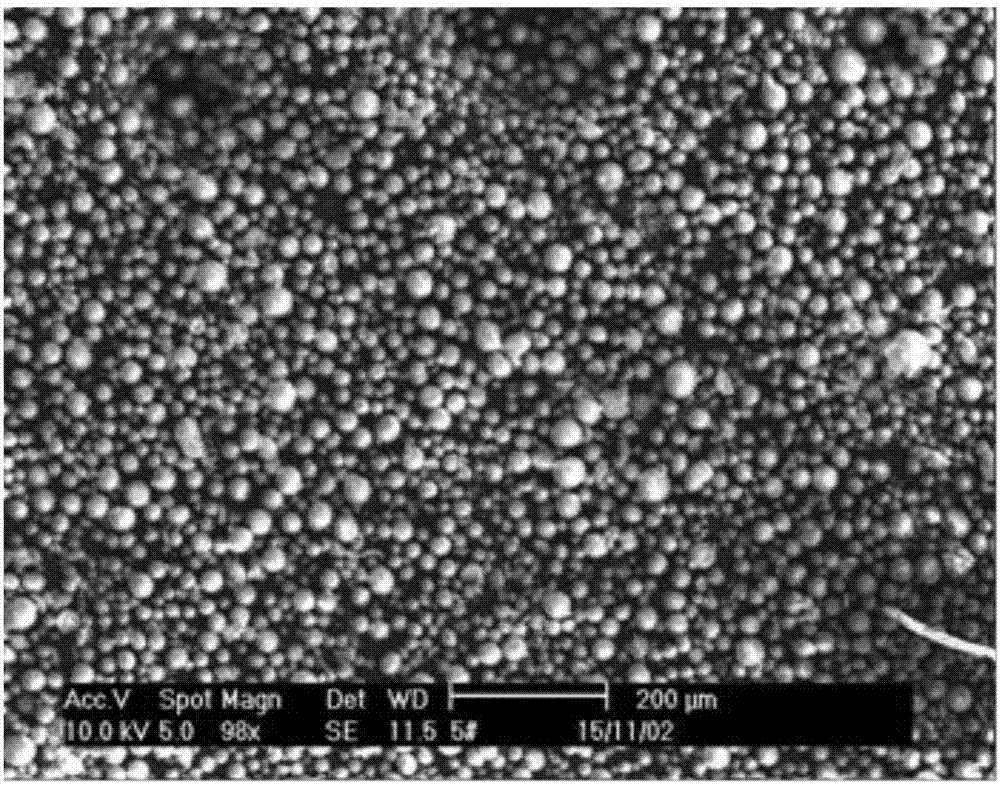

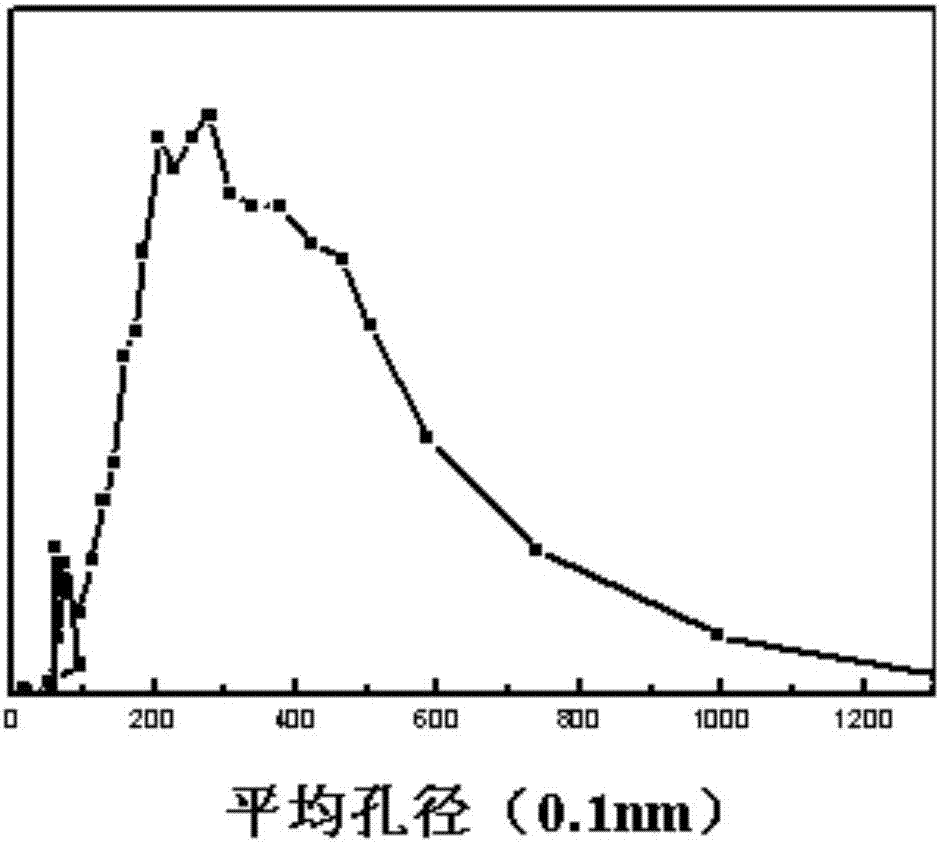

[0085] Add 1g (0.00017mol) of template agent P123 and 1.69g (0.037mol) of ethanol into 28mL of acetic acid and sodium acetate buffer solution with pH = 4.4, stir at 15°C until the template agent is completely dissolved, and add 6g (0.05mol) of three Add methylpentane to the above solution, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane to the above solution, stir at 15°C for 20h, then transfer the solution to the agate lining After crystallization in an oven at 60°C for 24 hours in a reaction kettle, filter and wash with deionized water for 4 times, and then suction filter to obtain a filter cake A1 of mesoporous molecular sieve material with a hollow spherical structure.

[0086] The water glass with a concentration of 15% by weight and the sulfuric acid solution and glycerin with a c...

Embodiment 2

[0109] This embodiment is used to illustrate the ethylene polymerization method provided by the present invention.

[0110] (1) Preparation of spherical composite materials

[0111] Add 1g (0.00017mol) template agent P123 and 1.4g (0.03mol) ethanol to 28mL of acetic acid and sodium acetate buffer solution with pH = 4.4, stir at 10°C until the template agent is completely dissolved, add 4.56g (0.04mol) Add trimethylpentane to the above solution, stir at 10°C for 8h, then add 1.83g (0.012mol) tetramethoxysilane to the above solution, stir at 10°C for 30h, then transfer the solution into agate In a lined reactor, after crystallization in an oven at 80°C for 20 hours, filter and wash with deionized water for 6 times, and then suction filter to obtain filter cake A2 of mesoporous molecular sieve material with a hollow spherical structure.

[0112] Water glass with a concentration of 20% by weight and a sulfuric acid solution with a concentration of 12% by weight and propylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com