High-yield preparation method of small-particle-size functional polymer nanospheres

A technology of nano-microspheres and polymers, which is applied in the field of high-yield preparation of small-diameter functional polymer nano-microspheres, which can solve the problems of reduced polymerization efficiency, low monomer concentration, and large size, and achieve improved curative effect and high The effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

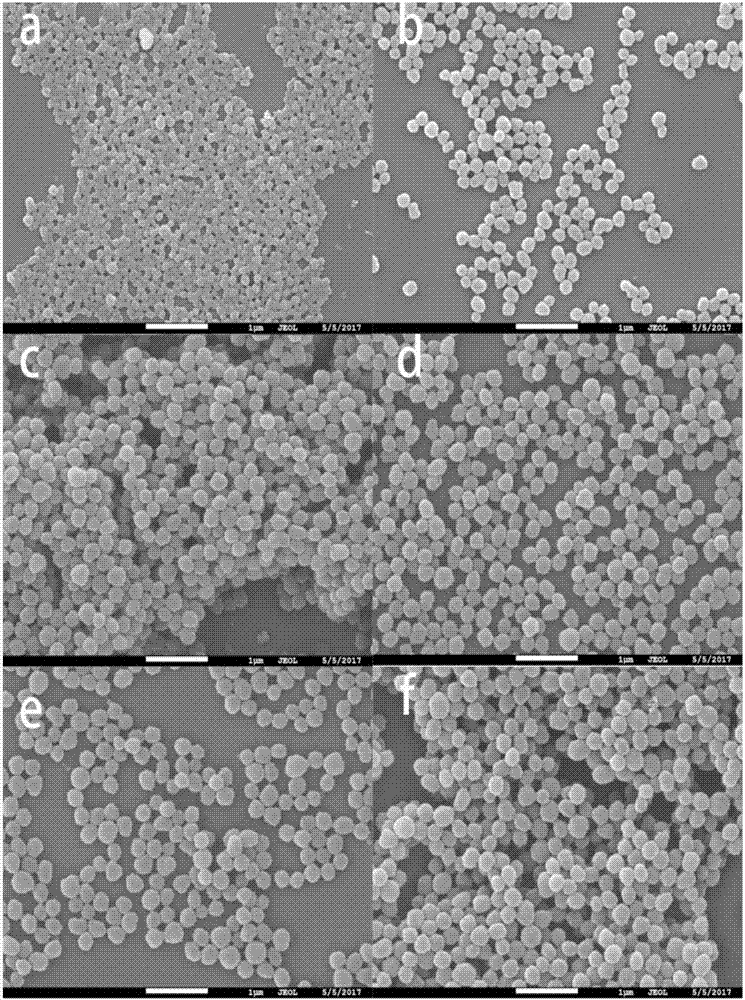

[0045] Example 1: Dissolve 1.04g of St and 0.98g of MAH in 50mL of isoamyl acetate, dissolve 0.007g of initiator ABVN in the above solution, pass nitrogen gas for 15min to remove oxygen in the system, and then heat the solution to 45°C Under the reaction 8h. After the reaction was completed, the reaction product was centrifuged at a speed of 4000 r / min for 10 min, and wasoamyl acetate and petroleum ether were added to wash and centrifuge three times. Vacuum-dried to constant weight to obtain functional copolymer nanospheres.

[0046] The yield calculated by gravimetric method is 74%, the microsphere particle size is about 184nm, and the particle size distribution coefficient is 1.03.

Embodiment 2

[0047] Example 2: Dissolve 1.04g of St and 0.98g of MAH in 50mL of isoamyl acetate, dissolve 0.009g of initiator ABVN in the above solution, pass nitrogen gas for 15min to remove oxygen in the system, and then heat the solution to 50°C Under the reaction 8h. After the reaction was completed, the reaction product was centrifuged at a speed of 4000 r / min for 10 min, and wasoamyl acetate and petroleum ether were added to wash and centrifuge three times. Vacuum-dried to constant weight to obtain functional copolymer nanospheres.

[0048] The yield calculated by the gravimetric method is 94%, the particle size of the microsphere is about 267nm, and the particle size distribution coefficient is 1.02.

Embodiment 3

[0049] Example 3: Dissolve 1.04g of St and 0.98g of MAH in 50mL of isoamyl acetate, dissolve 0.007g of initiator ABVN in the above solution, pass nitrogen gas for 15min to remove oxygen in the system, and then heat the solution to 60°C Under the reaction 8h. After the reaction was completed, the reaction product was centrifuged at a speed of 4000 r / min for 10 min, and wasoamyl acetate and petroleum ether were added to wash and centrifuge three times. Vacuum-dried to constant weight to obtain functional copolymer nanospheres.

[0050] The yield calculated by the gravimetric method is 94%, the microsphere particle size is about 278nm, and the particle size distribution coefficient is 1.02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com