Method for preparing electroconductive polymer compound for strain and/or pressure sensing

A conductive polymer and composite technology, applied in the field of mechanical sensors, can solve the problems of difficult to meet the large strain of the skin, destroy the aggregated structure, reduce the ductility of materials, etc., achieve excellent self-healing ability, high conductivity, long-term The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

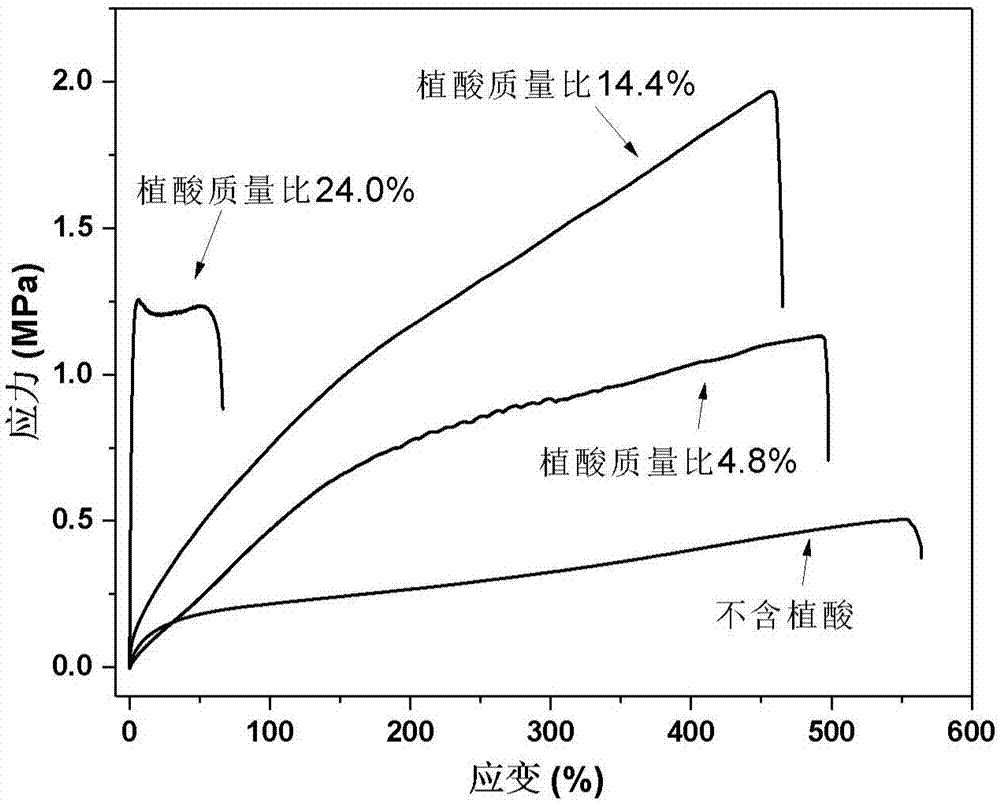

Embodiment 1

[0058]0.2g aniline, 3g concentration is the aqueous solution of the phytic acid of 50% by weight, 5g concentration is the aqueous solution (Mw=240000) of polyacrylic acid (Mw=240000) of 25% by weight by stirring and mixing to form a clear light yellow solution, get the aqueous solution of 1mL ammonium persulfate ( 0.87mmol) was added to the above mixed solution, stirred evenly, and reacted at 0-5°C for 12h to obtain an emerald green solution. Wherein, by calculation, based on the total weight of the emerald green solution, the amount of aniline is 1.9% by weight; the amount of phytic acid is 14.4% by weight; the amount of polyacrylic acid is 12% by weight; the amount of ammonium persulfate is 1.9% by weight %; and the amount of water is 69.8% by weight.

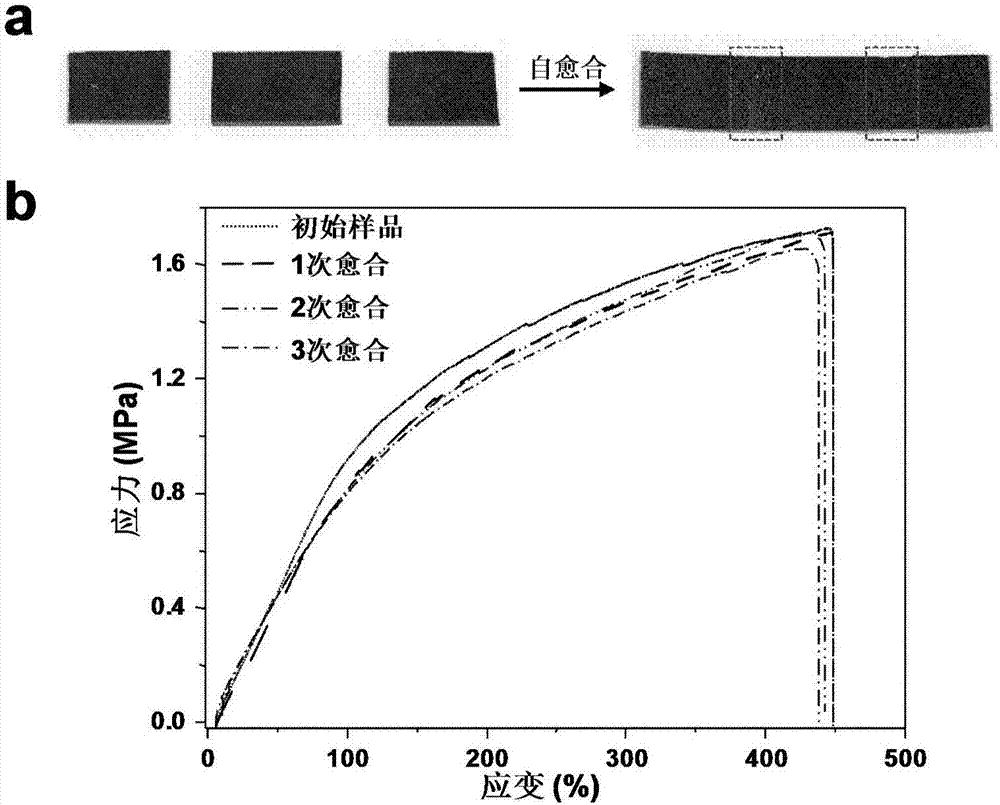

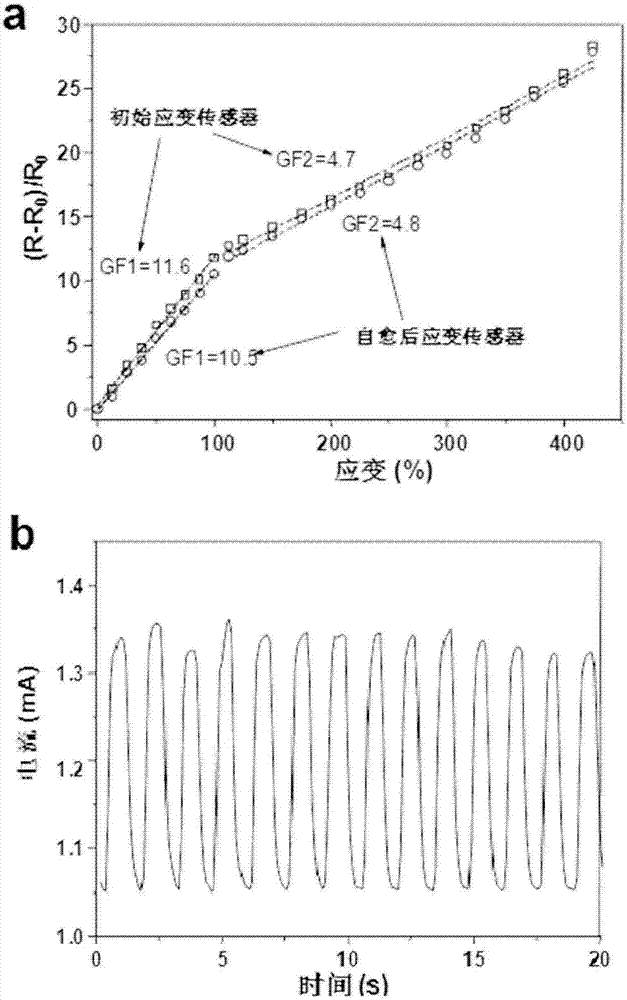

[0059] The obtained emerald green solution was coated on a common polytetrafluoroethylene mold with a flat bottom of 4cm×4cm×2mm in size, and the black polymer film 1 was obtained by evaporating the solvent at 30° C. for 24 h...

Embodiment 2

[0061] An experiment was performed in a similar manner to Example 1 except that the amount of phytic acid was changed to 4.8% by weight to obtain a black polymer film 2 .

Embodiment 3

[0063] An experiment was performed in a similar manner to Example 1 except that the amount of phytic acid was changed to 24.0% by weight to obtain a black polymer film 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com