Novel soft shape-maintenance knitted denim fabric production process

A technology for knitting denim and production technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of poor color fastness, lack of comfortable elasticity, rough texture, etc., and achieve good color fastness and excellent resistance to wet rubbing. The effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of production technology of novel soft shape-retaining knitted denim fabric, comprises the following steps:

[0037] 1) Fabric selection: fabric selection and weaving process.

[0038] Fabric A: experimental batch RD1500126; experimental cylinder number H100288.

[0039] Fabric A is 20S / 1 cotton (OE yarn)+16S / 1 combed cotton (slub yarn)+70D spandex single jersey twill, which has a denim effect.

[0040] Weaving process of fabric A

[0041] Requirements and attention points for gray fabric surface: use newly knitted knitted fabrics, and pay attention to the fact that there are no stitches or weaving on the surface of the fabric;

[0042] Row of knitting needles: 1st grade needle, 2nd grade needle, 3rd grade needle, the three kinds of needles are arranged in turn, and the 1.3.5 mold of all needles is added with spandex;

[0043] Row of knitting needle runway or row of water chestnut: as shown in Table 2.

[0044] Table 2: Λ means circle, n means tuck, - means f...

Embodiment 2

[0062] A kind of production technology of novel soft shape-retaining knitted denim fabric, comprises the following steps:

[0063] 1) Fabric selection: fabric selection and weaving process.

[0064] Fabric B: experimental batch RD1600408; experimental cylinder number H228157.

[0065] Fabric B is 30S / 1 Spun polyester + 20S / 1 combed cotton (slub yarn) single jersey twill with a denim effect.

[0066] Weaving process of cloth B

[0067] Requirements and points for attention on the fabric surface of the gray cloth: use newly knitted knitted fabrics, and pay attention to the fact that there are no stitches on the surface of the fabric, and there are no horizontal lines;

[0068] Row of knitting needles: 1st grade needle, 2nd grade needle, 3rd grade needle, the three kinds of needles are arranged in turn, and the 1.3.5 mold of all needles is added with spandex;

[0069] Row of knitting needle runway or row of water chestnut: as shown in Table 4.

[0070] Table 4: Λ means circle...

Embodiment 3

[0083] A kind of production technology of novel soft shape-retaining knitted denim fabric, comprises the following steps:

[0084] 1) Selection of cloth

[0085] Fabric A is 20S / 1 cotton (OE yarn)+16S / 1 combed cotton (slub yarn)+70D spandex single jersey twill, which has a denim effect.

[0086] 2) Cloth A pre-setting process: set the cloth at 190°C for 30 seconds.

[0087] Cloth A is used as the fabric.

[0088] 3) Pre-treatment: Add 0.5g / L penetrant, 1g / L caustic soda, and 1g / L hydrogen peroxide to the fabric, treat at 95°C for 20 minutes, then add 0.2g / L acetic acid and 0.01wt% deoxygenation to the fabric Enzymes carry out peracid deoxygenation treatment.

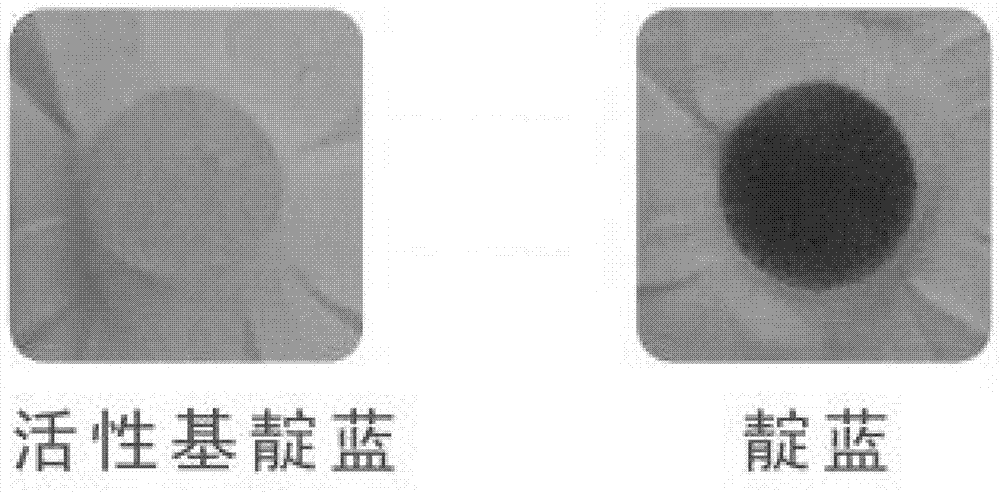

[0089] 4) Dyeing: Add reactive indigo dye, 50g / L industrial salt, and 10g / L industrial sodium carbonate to the fabric, and dye at 50°C for 40 minutes.

[0090] 5) Post-treatment: Soap the fabric with soaping agent 0.5g / L at 50°C for 10 minutes, and repeat twice.

[0091] 6) Post-finishing and finalizing: heat-settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com