Lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of preventing damage, improving high-rate performance, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

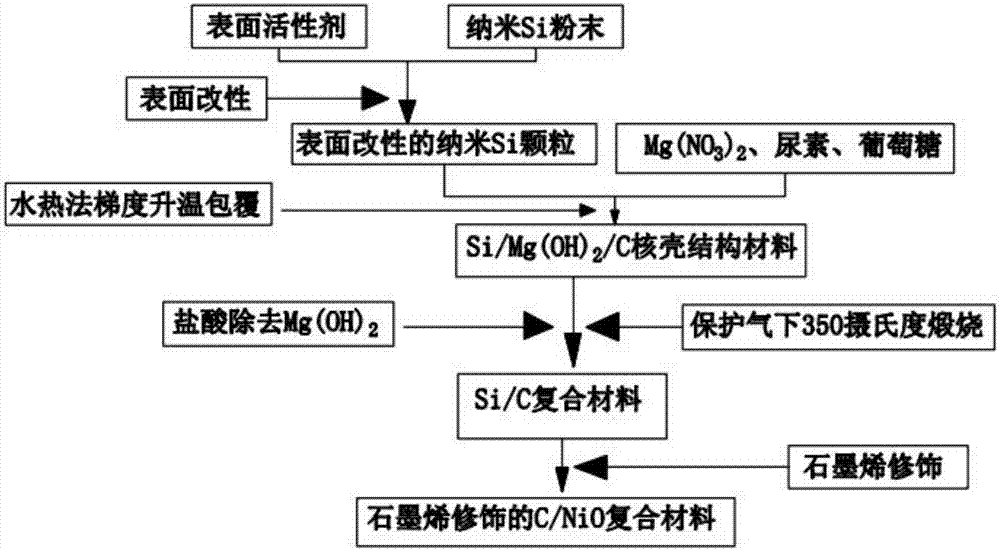

[0023] A preparation method of lithium ion battery negative electrode material is:

[0024] (1) Preparation of Si / Mg(OH) 2 / C material

[0025] The Si particles were surface-modified with a surfactant (ammonium bromide cetylbenzenesulfonate) so that the Mg(OH) 2 It is easy to coat on the surface of nano-Si powder. First, Si particles were dissolved in cetylbenzenesulfonate ammonium bromide aqueous solution, stirred and ultrasonically generated to form a mixed suspension, and then magnesium nitrate, urea and glucose were added to the above suspension and stirred for 3 h. Wherein, the molar ratio of Si, magnesium nitrate and urea is 1:1:3. Pour the fully stirred suspension into a polytetrafluoroethylene reactor and then put it into a homogeneous reactor to set a gradient temperature for the first reaction at 160°C for 3h, and then at 180°C for 6h. After the reaction was completed and cooled, the solid material was washed with deionized water and dried at 40° C. for 12 h.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com