Preparation method and application of nitrogen and phosphorus co-doped porous carbon

A co-doped, porous carbon technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve the problems of intolerance to carbon monoxide, methanol poisoning, poor stability, etc., and achieve strong methanol resistance. , strong anti-poisoning ability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

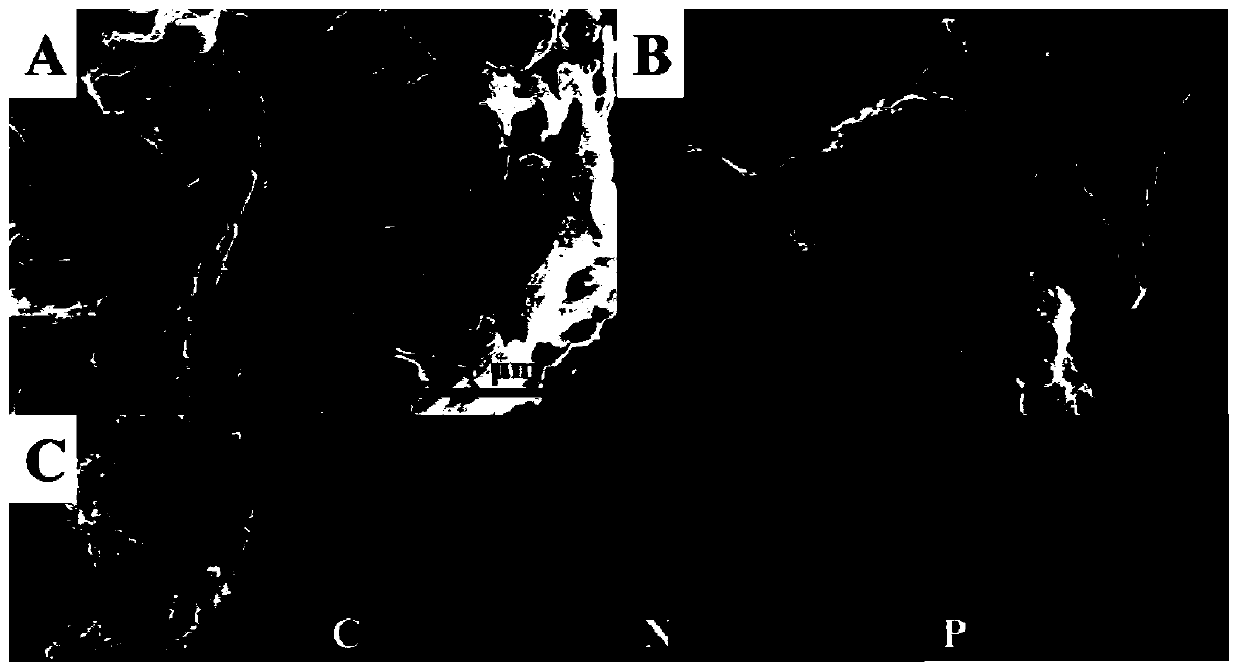

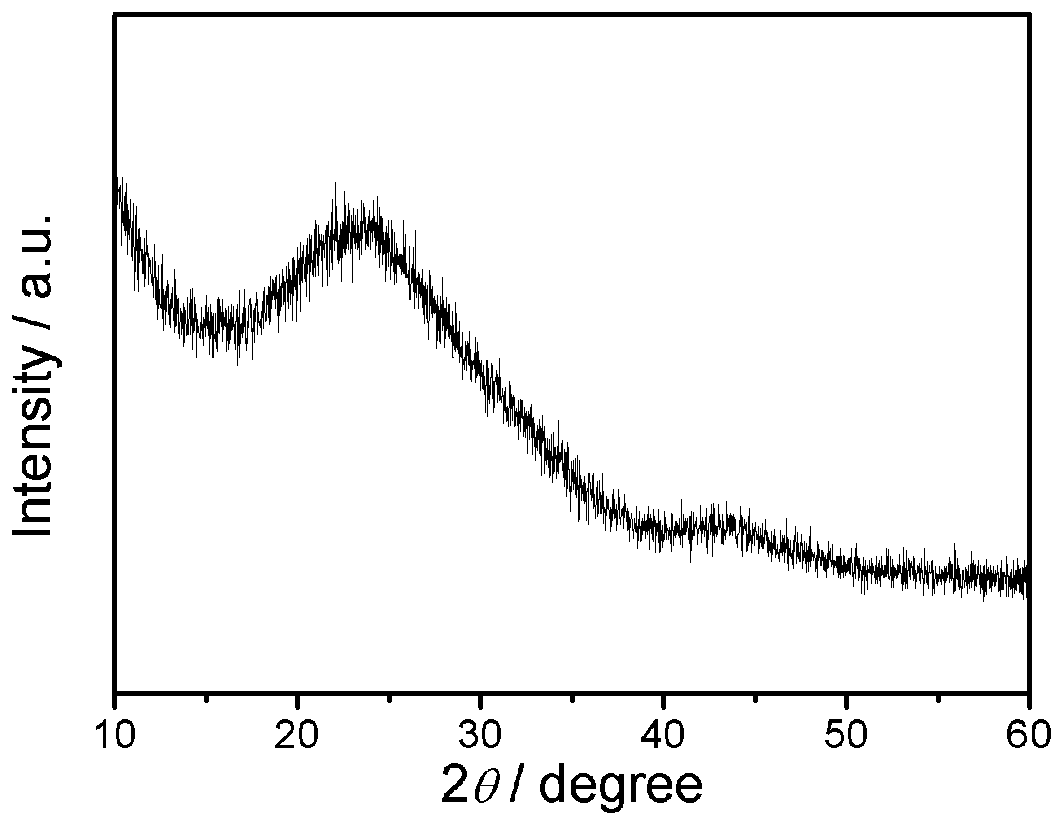

[0036] A preparation method of nitrogen and phosphorus co-doped porous carbon, comprising the following steps:

[0037] 1) Preparation of precursor copolymer: Weigh 3 mmol of melamine and add it to 20 mL of deionized water, stir well, add 1 mmol of adenosine triphosphate, stir well and add hydrochloric acid dropwise to adjust the pH value of the precursor copolymer to 3.0, so that the copolymer is white Gel-like, the product was freeze-dried to obtain a white fluffy powder.

[0038] 2) Preparation of nitrogen-phosphorous co-doped porous carbon material: put the precursor copolymer prepared in step 1) into a tube furnace, -1 The heating rate was increased to 900°C for 2 hours to prepare nitrogen and phosphorus co-doped porous carbon.

Embodiment 2

[0040] A preparation method of nitrogen and phosphorus co-doped porous carbon, comprising the following steps:

[0041] 1) Preparation of precursor copolymer: weigh 3mmol melamine and add it to 25mL deionized water, stir well, add 2mmol adenosine triphosphate, stir well and add hydrochloric acid dropwise to adjust the pH value of the copolymer to 2.5, making the copolymer a white gel The product was freeze-dried to obtain a white fluffy powder.

[0042] 2) Preparation of nitrogen-phosphorous co-doped porous carbon material: put the precursor copolymer prepared in step 1) into a tube furnace, and heat it at 1.5°C min -1 The heating rate was raised to 1000°C and calcined for 1.5h to prepare nitrogen and phosphorus co-doped porous carbon.

Embodiment 3

[0044] A preparation method of nitrogen and phosphorus co-doped porous carbon, comprising the following steps:

[0045] 1) Preparation of precursor copolymer: Weigh 3mmol melamine and add it to 30mL deionized water, stir well, add 3mmol adenosine triphosphate, stir well and add hydrochloric acid dropwise to adjust the pH value of the copolymer to 2.5, until the copolymer is a white gel The product was freeze-dried to obtain a white fluffy powder.

[0046] 2) Preparation of nitrogen-phosphorus co-doped porous carbon material: put the precursor copolymer prepared in step 1) into a tube furnace, and heat it at 2.5°C min -1 The heating rate was increased to 700°C for 2.5h to prepare nitrogen and phosphorus co-doped porous carbon.

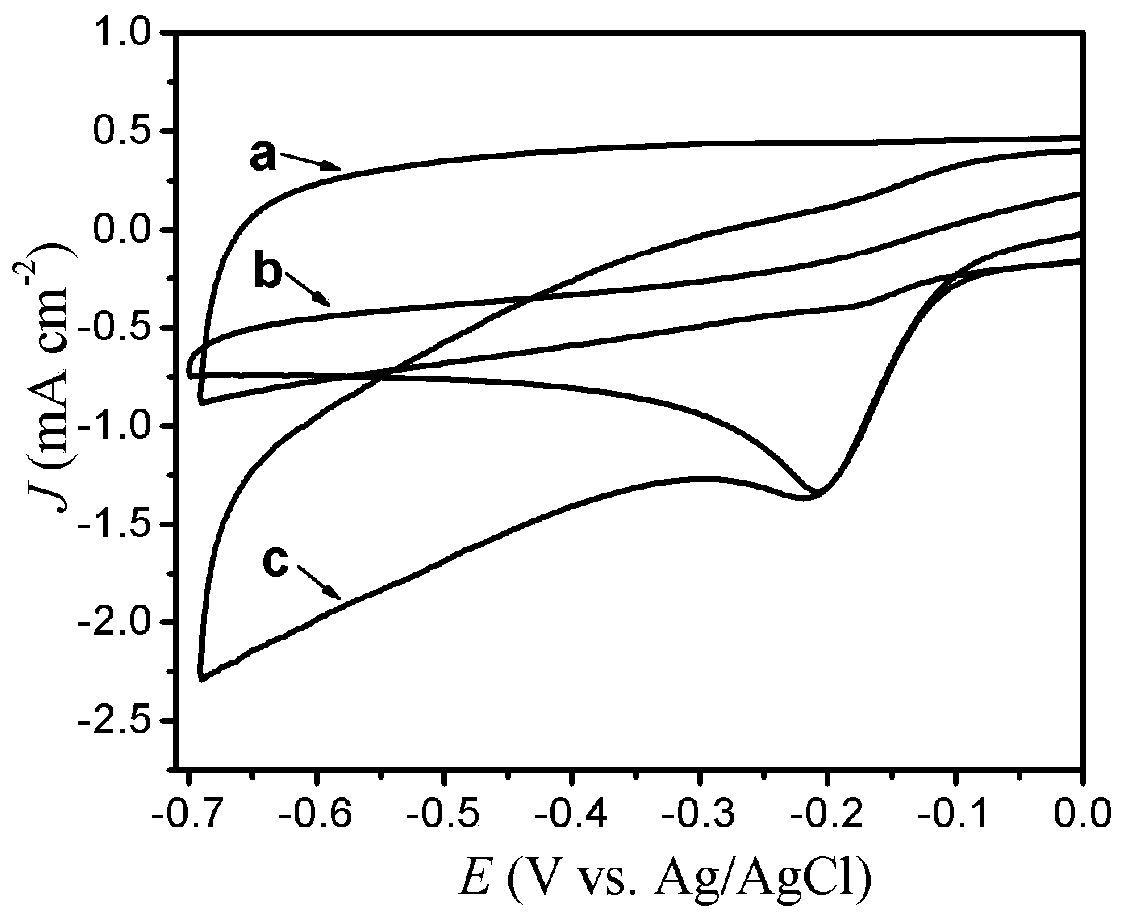

[0047] Electrocatalytic oxygen reduction test, including the following steps:

[0048]1) The glassy carbon electrode (3 mm in diameter) is processed through the following steps: first, it is ground and polished with 0.3 μm alumina powder to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com