Preparation method and application of magnetic organic modified nano adsorption material

A nano-adsorption material and magnetic technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, inorganic chemistry, etc., can solve the problems of the ability to adsorb heavy metals needs to be strengthened, inconvenient to recycle, etc., to achieve rich raw materials, high adsorption performance, The effect of pore structure development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

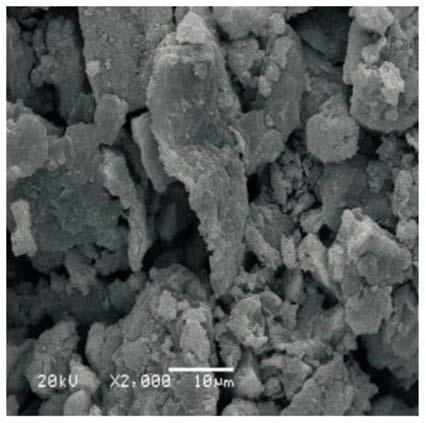

Image

Examples

Embodiment 1

[0032] (1) Magnetic Fe 3 o 4 preparation of

[0033] Weigh 6.88g of sodium citrate and dissolve it in 160mL of deoxygenated water, then quickly add 2g of FeCl 2 4H 2 O, 1gFeCl 3 ·6H 2 O, immediately seal with plastic wrap, and add 160ml of 2mol / L sodium hydroxide solution without stirring, let it stand for 3-4 hours, then seal and heat to boiling, after cooling, suction filter and dry to obtain Fe 3 o 4 particles.

[0034] (2) Preparation of xonotlite adsorption material

[0035] Soak discarded eggshells in tap water for 2 to 3 hours, clean them, add them to a 5% sodium hydroxide solution and heat to 95°C to remove the inner membrane in the eggshell, and remove the eggshell and sodium hydroxide solution. The mass ratio is 1:2, then washed with distilled water, dried, and crushed into powder with a grinder to obtain fresh CaO, which is sealed for future use. Weigh 4g of freshly prepared CaO, add 40ml of 90°C deionized water, and react for 30min under the stirring of a ...

Embodiment 2

[0042]The application of the magnetic organically modified nano-adsorption material of a kind of embodiment 1 in removing the cadmium-containing waste water of different pH, concrete application method is:

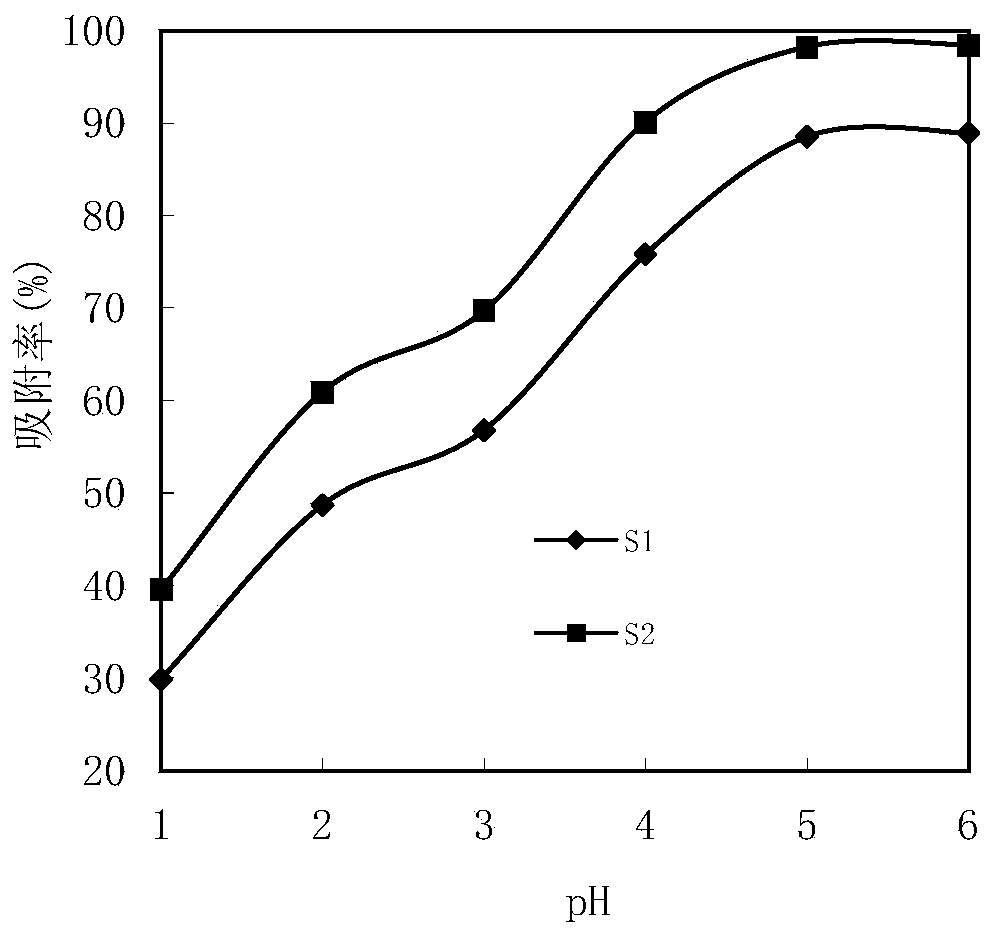

[0043] Take 6 parts of Cd with a concentration of 25mg / L 2+ 100mL of simulated wastewater solution is placed in a 250mL conical flask, and the xonotlite S1 prepared by step (2) in Example 1, the magnetic organically modified calcium silicate prepared by step (4) are added in each conical flask Stone S2 (added at 1g / L), use 0.1mol / L HCl and 0.1mol / L NaOH to adjust the pH to 1, 2, 3, 4, 5, 6 respectively, control the temperature to 30°C, and shake at a speed of 150r / min , placed in a water bath constant temperature oscillator for 60 minutes, left to stand for 10 minutes, filtered, and the filtrate was taken to measure the residual Cd 2+ concentration. The measurement results are attached figure 2 : Compared with unmodified xonotlite, the magnetic organically modified nan...

Embodiment 3

[0045] An application of the magnetic organically modified nano-adsorption material of Embodiment 1 in removing cadmium-containing wastewater, the specific application method is:

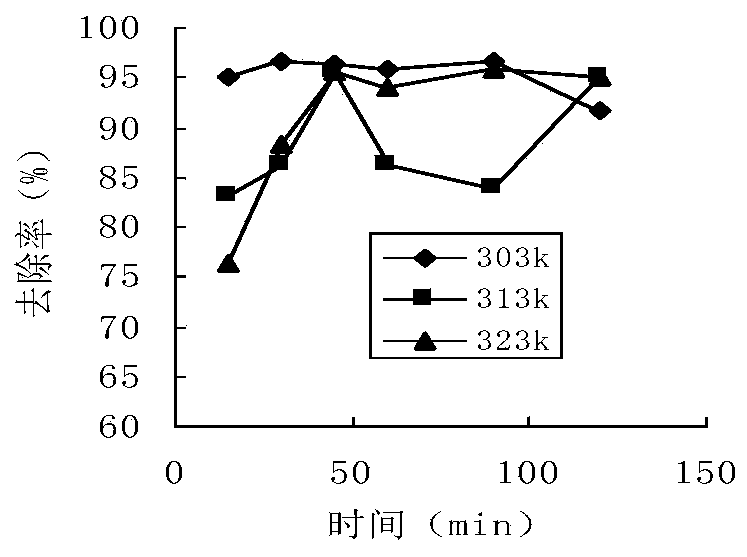

[0046] The magnetic organically modified nano-adsorption material of embodiment 1 is added to pH value 6 by 1g / L, Cd 2+ In the cadmium-containing wastewater with a concentration of 25mg / L, set the temperature at 303K, 313K, 323K, and oscillate for 90 minutes in a water bath constant temperature oscillator with an oscillation speed of 150r / min. After the start of constant temperature oscillation adsorption, 15min, 30min, 45min, 60min, and 75min respectively , Detect the concentration of cadmium in cadmium-containing wastewater for 90 minutes, and calculate the adsorption rate. Test results such as image 3 Shown: After 45 minutes of adsorption, the adsorption basically reached equilibrium, and the higher the temperature, the lower the removal rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com