Scheelite depressing agent and preparation process thereof

A preparation process and inhibitor technology, applied in flotation, solid separation, etc., can solve the problem of single flotation, achieve the effect of improving grade and recovery rate, reducing treatment amount, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The scheelite flotation inhibitor used in this embodiment consists of the following components in terms of mass fraction:

[0020] Liquid sodium silicate 40%, sulfuric acid 20%, copper sulfate 15%, carboxymethyl cellulose 10%, lead nitrate 15%.

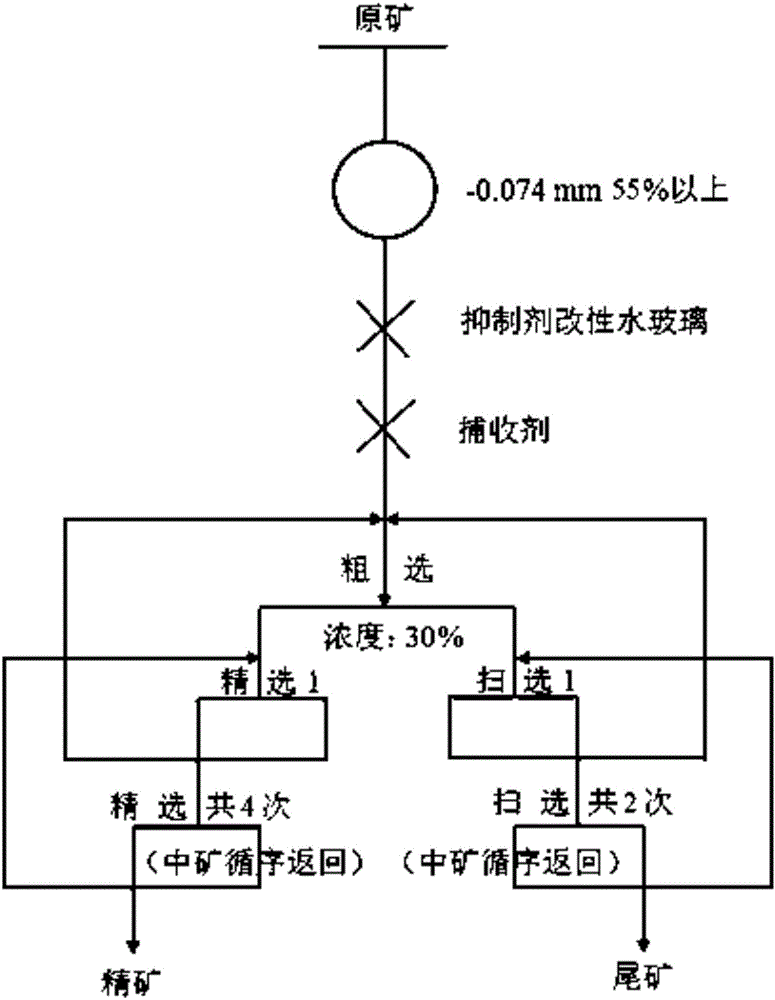

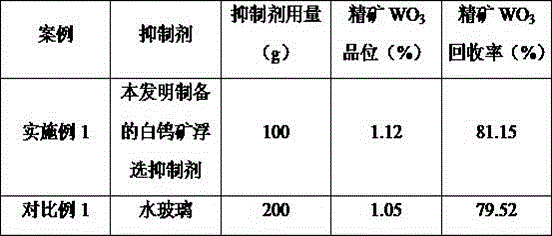

[0021] In this embodiment, a certain low-grade scheelite ore sample, ore grade WO 3 0.096%. For the test procedure of the pharmaceutical system, see figure 1 , under the premise that other reagent systems remain unchanged, the experimental results of contrasting water glass and the scheelite flotation inhibitor prepared by the present invention are shown in Table 1.

[0022] The collector described in this example is fatty acid soap. The collector is added at the rate of 300 g of collector per ton of raw ore.

[0023] The specific operation is as follows: the raw ore is ground until the particle size is less than or equal to 0.074mm, and the particles account for more than 55% of the total mass of the raw ore, and then the...

Embodiment 2

[0029] The scheelite flotation inhibitor used in this embodiment consists of the following components in terms of mass fraction:

[0030] Liquid sodium silicate 40%, sulfuric acid 20%, copper sulfate 15%, carboxymethyl cellulose 10%,

[0031] Lead nitrate 15%.

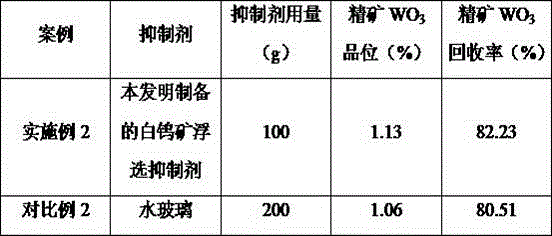

[0032] In this embodiment, a certain low-grade scheelite ore sample, ore grade WO 3 0.097%, the pharmaceutical system test process see figure 1 , under the premise that other reagent systems remain unchanged, the experimental results of comparing water glass and the scheelite flotation inhibitor prepared by the present invention are shown in Table 2.

[0033] The collector described in this example is fatty acid soap. The collector is added at the rate of 300 g of collector per ton of raw ore.

[0034] The specific operation is as follows: the raw ore is ground until the particle size is less than or equal to 0.074mm, and the particles account for more than 55% of the total mass of the raw ore, and then the pulp i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com