Preparation method for MoS2/CC (molybdenum disulfide/carbon cloth) composite hydrogen evolution electro-catalytic material

An electrocatalytic material, molybdenum disulfide technology, which is applied in the field of electrocatalytic hydrogen evolution to achieve the effects of small nanometer size, uniform distribution and wide interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0014] The preparation of embodiment 1 molybdenum disulfide / carbon cloth composite catalyst

[0015] Weigh 582.7mg of phosphomolybdic acid and 1165.3mg of thiourea and dissolve them in 46ml of deionized water and stir for 1-2 hours to obtain a mixed solution, then take 4ml, 6ml, 12ml, 24ml respectively (marked as MoS 2 / CC-1,MoS 2 / CC-2,MoS 2 / CC-3,MoS 2 / CC-4) solution was transferred to a 50ml reaction kettle, and then diluted to 30ml respectively. Put the carbon in the solution and ultrasonically make the solution completely wet the carbon cloth, heat it in water at 180 degrees Celsius for 24 hours, then cool it down to room temperature naturally, wash the obtained product with deionized water and ethanol in turn, filter it, and place it in a vacuum drying oven Dry at 60°C for 8 hours.

Embodiment 2

[0016] Example 2 MoS 2 Characterization and Analysis of / CC Composite Catalyst

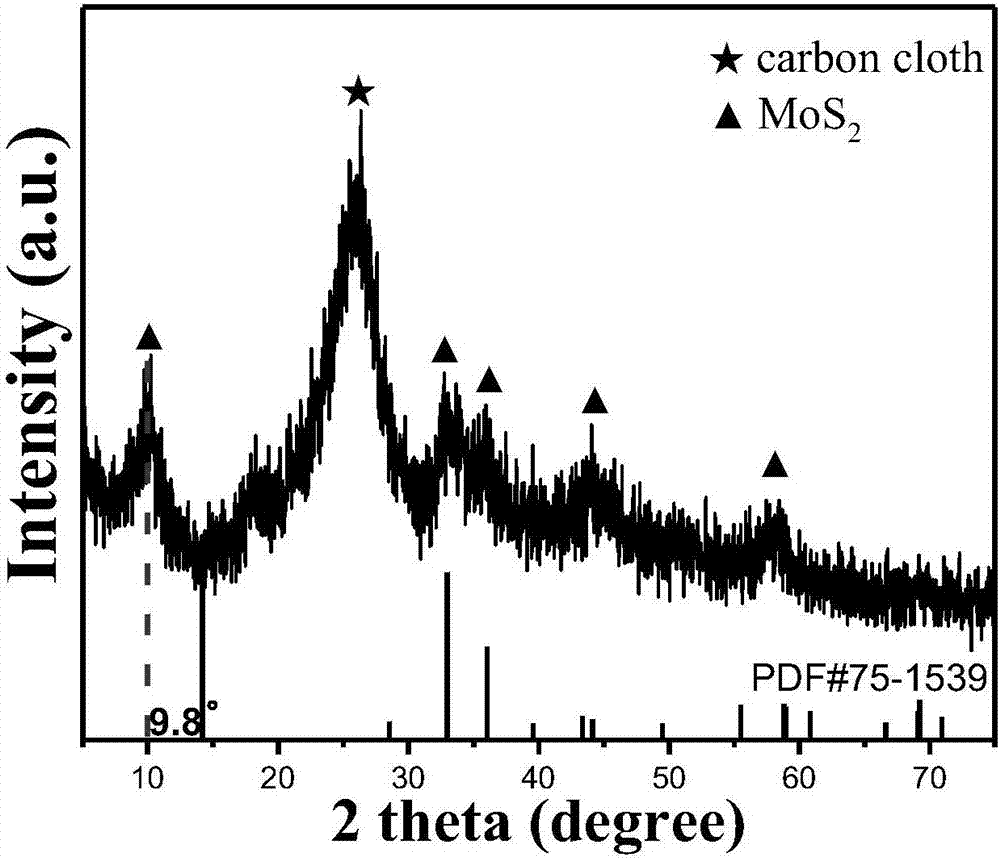

[0017] like figure 1 As shown, it can be seen from the figure that there is MoS 2 and the diffraction peaks of carbon cloth, without other impurity phases, and MoS 2 The peak corresponding to the (002) crystal plane shifted to 9.8°, indicating that the interlayer spacing of the molybdenum disulfide we obtained was widened.

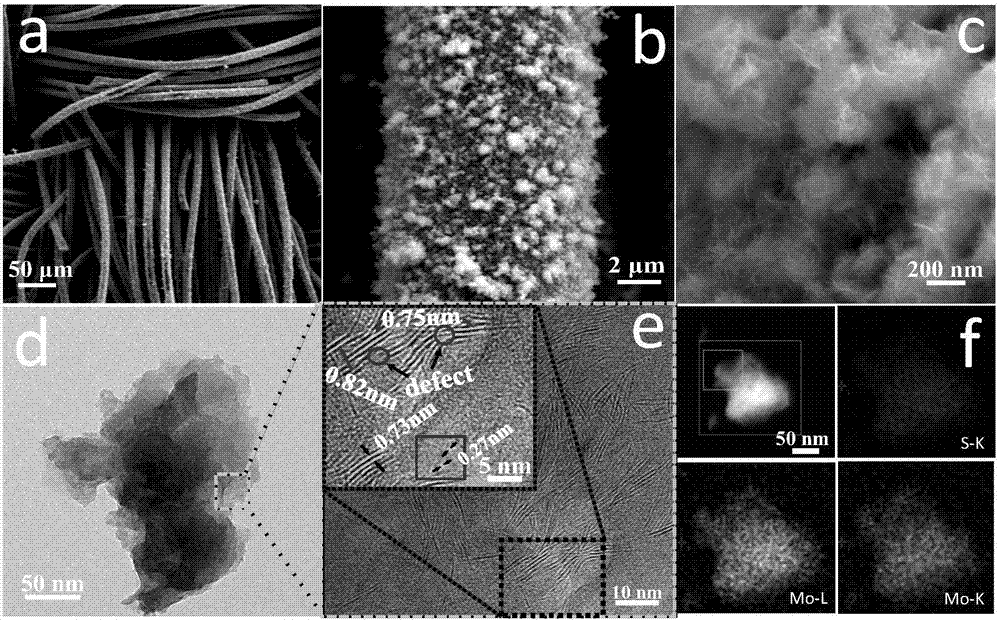

[0018] like figure 2 As shown, it can be seen from Figures a and b that molybdenum disulfide is evenly grown on the carbon cloth. Figure d shows that the molybdenum disulfide nanosheets are about 100-150nm. Figure e shows that molybdenum disulfide is rich in many defects, and the inlay shows that the interlayer spacing is about 0.75-0.82nm wide.

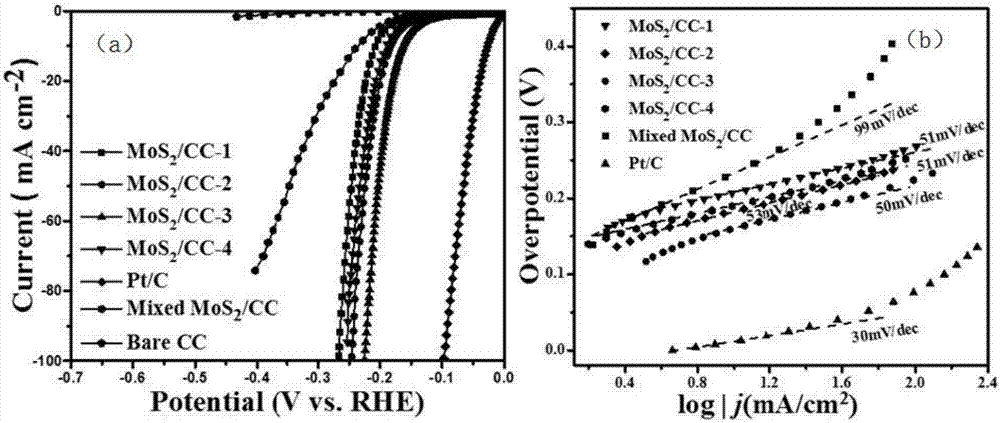

[0019] like image 3 As shown, the MoS can be clearly seen in the figure 2 The / CC composite electrocatalyst has excellent electrocatalytic hydrogen evolution performance in acidic environment. MoS 2 / CC-3 has the highest e...

Embodiment 3

[0021] Example 3 MoS 2 Electrocatalytic Hydrogen Evolution Activity Experiment of / CC Composite Catalyst

[0022] Using a three-electrode system for MoS 2 The electrocatalytic hydrogen evolution performance of the / CC composite hydrogen evolution electrocatalytic material was tested. The graphite rod was used as the counter electrode, the saturated calomel electrode (SCE) was used as the reference electrode, and the catalyst was used as the working electrode; the test instrument was Shanghai Chenhua CHI 760e electrochemical Workstation; the test solution is 0.5mol / L H 2 SO 4 Solution, 0.5mol / L sodium phosphate buffer solution, 1mol / L KOH solution.

[0023] Test parameters: LSV test scan rate 5mV / s.

[0024] The electrocatalytic hydrogen evolution performance test results of the composite electrocatalytic hydrogen evolution material of the present invention in acid are as follows: image 3 Medium, MoS 2 / CC-3 composite electrocatalytic hydrogen evolution material has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com