Upgrading and silicon-reduction direct flotation method for silicate type hematite and limonite rough flotation concentrate

A technology of hematite and silicate, applied in flotation, solid separation, etc., can solve the problems of high cost, low yield, energy consumption, etc., achieve high yield and recovery, reduce production cost, The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0033] Table 1 shows the chemical properties of the iron concentrate obtained from the silicate-type red limonite of the Dahongshan Iron Mine using three roughing methods, and the particle size analysis is shown in Table 2.

[0034] Table 1 Chemical Properties of Rough Concentrate (%)

[0035]

[0036] It can be seen from Table 1 that the iron minerals of the three samples are mainly red limonite, and the magnetic iron content is small, especially the third-stage strong magnetic concentrate of the third concentrator hardly contains magnetic iron, which gives red limonite The reprocessing of small iron concentrates increases the difficulty. The silicon content in the three samples was high, resulting in excessive impurities in the concentrate.

[0037] Table 2 Rough Concentrate Particle Size (%)

[0038]

[0039] From the particle size distribution results in Table 2, it can be seen that the SiO 2 The grade in the coarse-grained section is as high as 30%. This part of ...

Embodiment 1

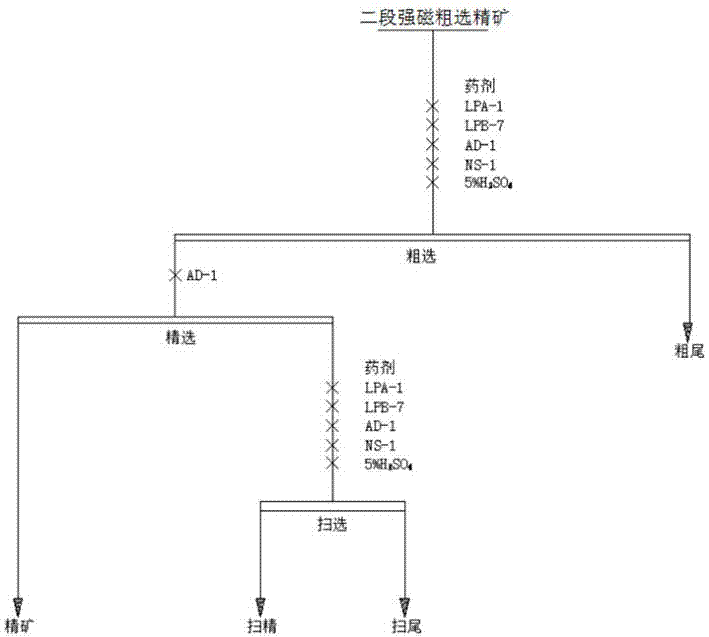

[0041] The second-stage strong magnetic roughing iron concentrate in Experimental Example 1 is used as the raw ore to carry out "one rough one fine one sweep" positive flotation, the steps are as follows:

[0042] S100: Add water to the second-stage strong magnetic roughing iron concentrate to adjust the slurry to a concentration of 35%, then put the slurry into the roughing flotation equipment, and add 500g / t of LPA- 1 and 500g / t of LPB-7 collector, 600g / t of AD-1 inhibitor, 250g / t of NS-1 auxiliary collector, 5ml / t of 5% H 2 SO 4 As a pH adjuster, it is stirred for positive flotation to obtain rougher concentrate foam and rougher tailings;

[0043] S200: Put the above-mentioned roughing concentrate foam into the beneficiation flotation equipment, add 300g / t of AD-1 inhibitor according to the amount of dry ore fed to the flotation, and carry out positive flotation after stirring to obtain the beneficiation concentrate and selected tailings;

[0044] S300: Put the above-men...

Embodiment 2

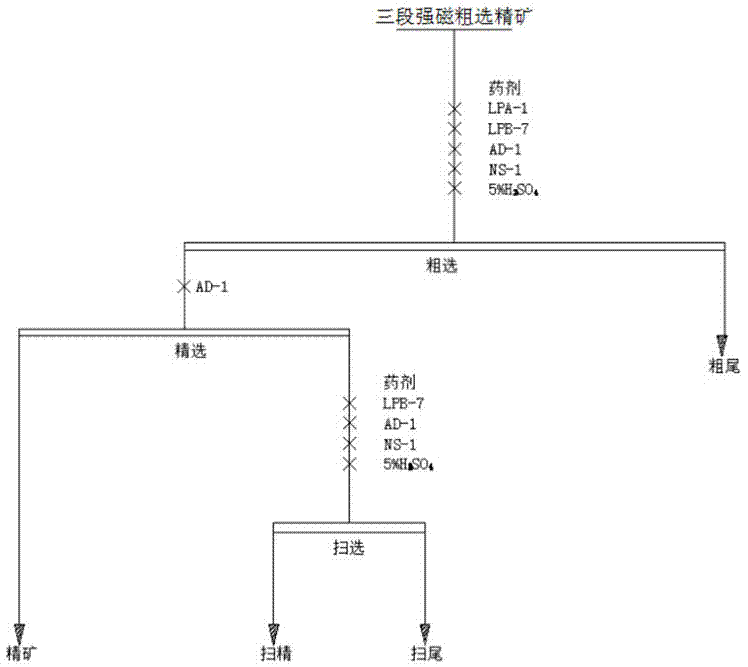

[0049] The second-stage strong magnetic roughing iron concentrate in Experimental Example 1 is used as the raw ore to carry out "one rough one fine one sweep" positive flotation, the steps are as follows:

[0050] S100: Add water to the second-stage strong magnetic roughing iron concentrate to adjust the slurry to a concentration of 40%, then put the slurry into the roughing flotation equipment, and add 550g / t of LPA- 1 and 450g / t of LPB-7 collector, 600g / t of AD-1 inhibitor, 300g / t of NS-1 auxiliary collector, 6ml / t of 5% H 2 SO 4 As a pH adjuster, it is stirred for positive flotation to obtain rougher concentrate foam and rougher tailings;

[0051] S200: put the above-mentioned roughing concentrate foam into the beneficiation flotation equipment, add 350g / t of AD-1 inhibitor according to the amount of dry ore fed to the flotation, and carry out positive flotation after stirring to obtain the beneficiation concentrate and selected tailings;

[0052] S300: Put the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com