Flexible continuous carbon fiber self-heating element and structure thereof

A carbon fiber heating and carbon fiber technology, used in drill pipes, casings, drill pipes, etc., can solve the problems of unstable heating and energization, uneven heating temperature of the rod body, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] On the surface of the PTFE insulating layer with a thickness of 1 mm, unidirectional spiral winding and weaving of T300 reinforcing fibers is performed, and then the fabric is impregnated with epoxy resin, and finally an outer layer 1 of carbon fiber composite material with a glue content of 40% and a thickness of 1 mm is prepared.

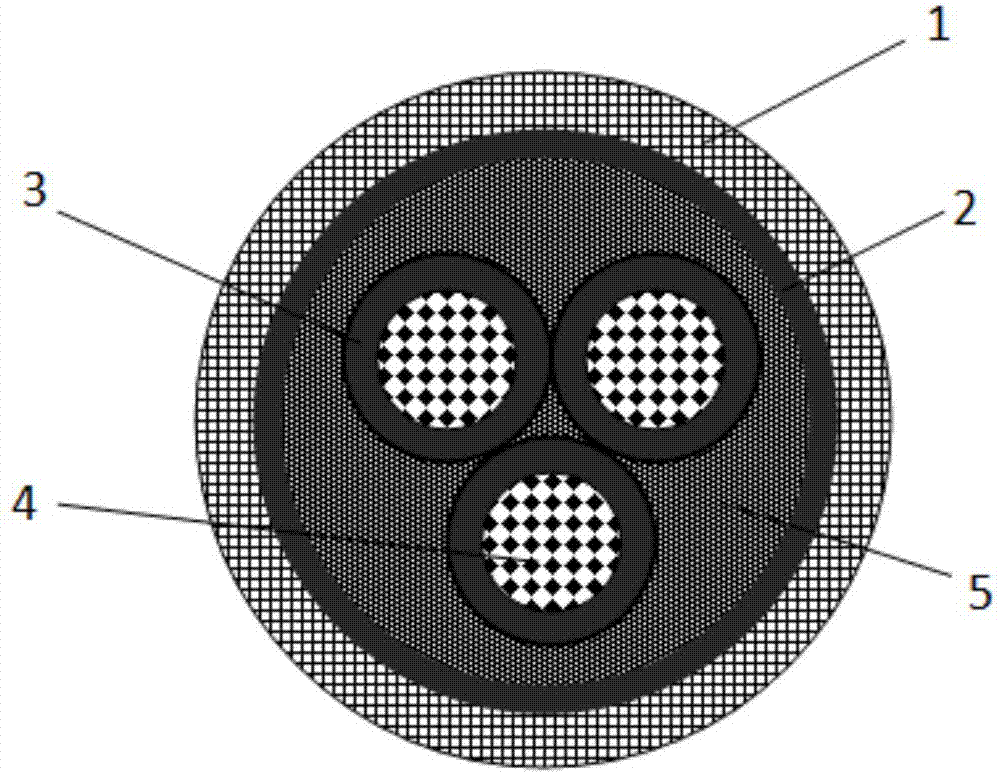

[0028] The interior of the braided outer layer of carbon fiber composite material is a polytetrafluoroethylene insulation layer 2, and the interior of the insulation layer is three flexible carbon fiber heating wires arranged according to the center of the circle. The surface of the heating wire is a polytetrafluoroethylene insulating layer 3 with a thickness of 0.1-2mm, and the inside of the insulating layer 3 is T300, T700, T800, M40, M60 carbon fiber heating wires woven with unidirectional carbon fiber, two-dimensional plain weave, twill weave, and satin weave 4. Magnesium oxide powder filler 5 with a particle size of 10nm is filled betw...

Embodiment 2

[0030] A two-dimensional plain weave fabric of T700 reinforced fibers was woven on the surface of the PTFE insulating layer with a thickness of 0.5 mm, and then the fabric was impregnated with phenolic resin to finally prepare a carbon fiber composite outer layer 1 with a glue content of 50% and a thickness of 1 mm.

[0031] The interior of the braided outer layer of carbon fiber composite material is a polytetrafluoroethylene insulation layer 2, and the interior of the insulation layer is four flexible carbon fiber heating wires arranged according to the center of the circle. The surface of the heating wire is a polytetrafluoroethylene insulating layer 3 with a thickness of 0.7mm, and the inside of the insulating layer 3 is a T800 carbon fiber heating wire 4 with two-dimensional satin weaving. Alumina powder filler 5 with a particle size in the range of 1 μm is filled between the 4 parallel heating wires arranged in the center of the circle and the surface insulating layer 2. ...

Embodiment 3

[0033] A two-dimensional satin weave of T800 reinforced fiber is added to the surface of the PTFE insulating layer with a thickness of 0.9mm, and then the fabric is impregnated with unsaturated polyester resin, and finally a carbon fiber composite material with a glue content of 40% and a thickness of 2mm is prepared. Layer 1.

[0034] The interior of the braided outer layer of carbon fiber composite material is a polytetrafluoroethylene insulating layer 2, and the interior of the insulating layer is 6 flexible carbon fiber heating wires arranged according to the center of the circle. The surface of the heating wire is a polytetrafluoroethylene insulating layer 3 with a thickness of 0.2 mm, and the inside of the insulating layer 3 is a unidirectional T700 carbon fiber heating wire 4 . Zirconia powder filler 5 with a particle size in the range of 2 μm is filled between the six parallel heating wires arranged in the center of the circle and the surface insulating layer 2. The he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com