Preparation method of small-sized ultra-dispersed nano zirconium oxide-based coating powder

A zirconia-based, coating powder technology, applied in zirconia, nanotechnology and other directions, to achieve the effect of high repeatability, low process cost, preventing growth and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, anhydrous zirconium chloride (23.32g) was dissolved in absolute ethanol (500ml) to form a zirconium chloride ethanol solution, then caustic soda (16g) was added to the zirconium chloride ethanol solution, fully Mix for 30 minutes, then use a separator to remove the remaining ethanol solution, and after drying at 60°C, introduce the hydroxide precipitation mixture into a crucible, and calcinate at 600°C for 2 hours. Finally, the small-sized, ultra-dispersed nano-zirconia (ZrO 2 ) coating powder.

Embodiment 2

[0041] First, anhydrous zirconium chloride (21.13g) and anhydrous yttrium chloride (1.84g) were dissolved in absolute ethanol (500ml) to form a mixed chloride ethanol solution, and then caustic soda (13.37g) was added to the mixture In the chloride ethanol solution, mix thoroughly under stirring conditions for 30 minutes, then use a separator to remove the remaining ethanol solution, after drying at 60°C, import the hydroxide precipitation mixture into a crucible, and calcinate at 600°C Keep warm for 2 hours. Finally, the small-sized, super-dispersed yttria-stabilized nano-zirconia (YSZ) coating powder is obtained by repeated and alternate washing with water and ethanol solution three times.

Embodiment 3

[0043] First, dissolve anhydrous zirconium chloride (21.13g), anhydrous yttrium chloride (0.92g), and anhydrous cerium nitrate (1.54g) in anhydrous methanol (500ml) to form a mixed chloride and nitrate methanol solution , then add caustic soda (13.37g) into the mixed chloride and nitrate methanol solution, and mix thoroughly under stirring for 30 minutes, then use a separator to remove the remaining methanol solution, and dry it at 60°C. The hydroxide precipitated mixture was introduced into the crucible, and calcined at 600°C for 2 hours. Finally, the small-sized, super-dispersed ceria-yttria-stabilized nano-zirconia (CYSZ) coating powder is obtained through repeated and alternate washing with water and ethanol solution three times.

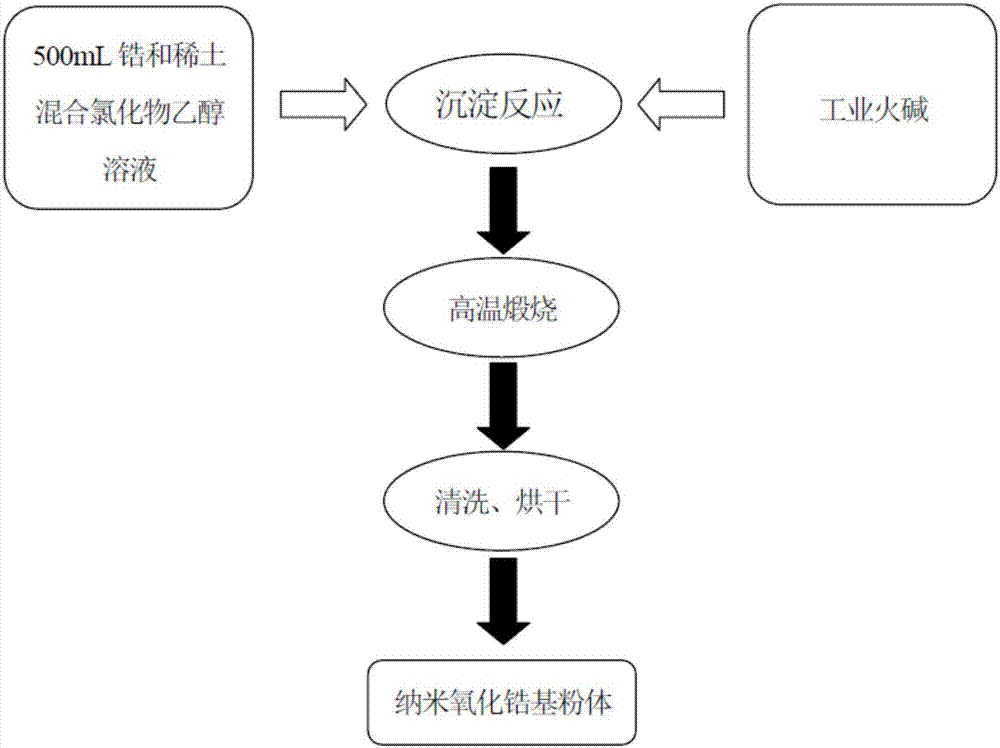

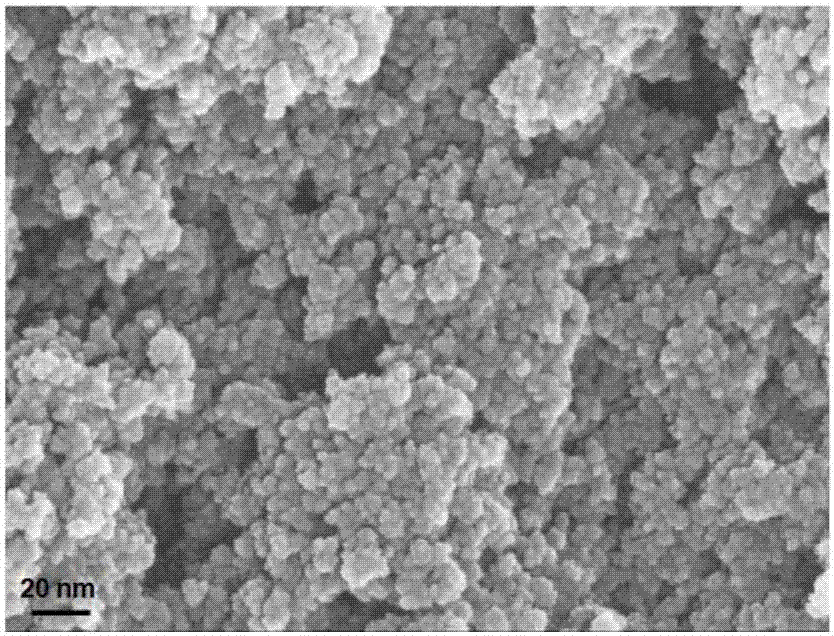

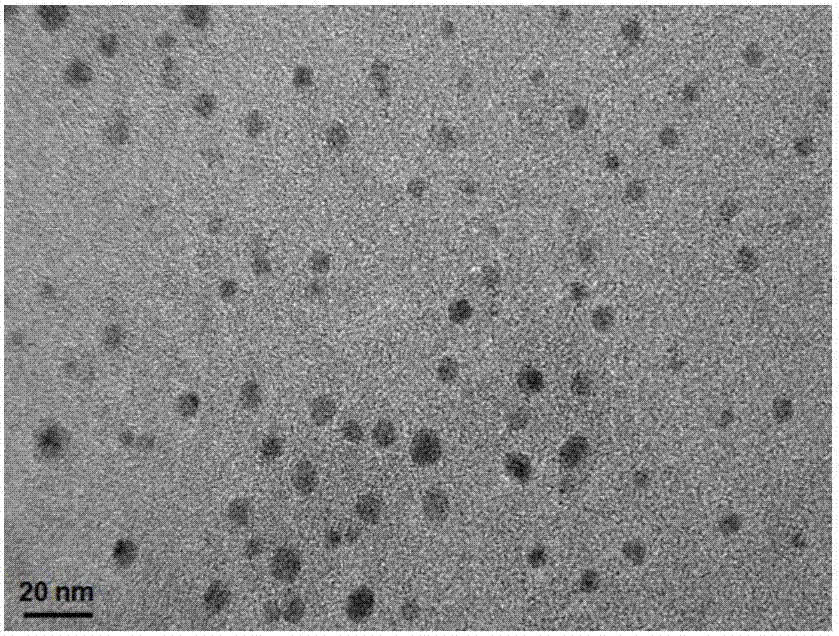

[0044] Figure 2a , Figure 2b , Figure 3a , Figure 3b , Figure 4a and Figure 4b These are the SEM and TEM topography images of the zirconia-based coating powders prepared in Examples 1-3 of the present invention, respectively. The av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com