As-cast finish concrete

A technology of fair-faced concrete and aqueous solution, which is applied in the field of building materials, can solve problems such as poor impermeability and anti-carbonation performance, and poor crack resistance, and achieve the effects of high toughness and strength, improved impermeability, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

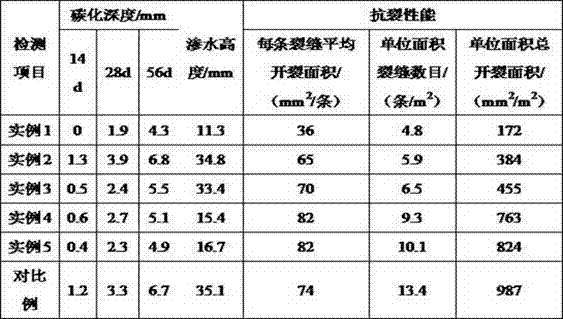

Examples

example 1

[0021] Add peach gum and water into the beaker at a mass ratio of 1:60, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the beaker into a magnetic stirrer with digital display speed measurement and constant temperature, at a temperature of 40°C and a speed of 500r / min Under certain conditions, heat and stir to dissolve for 40 minutes to obtain peach gum solution; add coconut carbon fiber and 8% sodium hydroxide solution in a mass ratio of 1:20 into a single-necked flask, and then move the single-necked flask into a digital speed measuring constant temperature magnetic stirrer , stirred and mixed for 2 hours at a rotating speed of 500r / min to obtain a mixed solution, then filtered the mixed solution to obtain a filter cake, then washed the filter cake with deionized water for 5 times, and then placed the filter cake in a freezer pulverizer to freeze Grinding for 30 minutes to obtain the crushed material, and then drying the crushed ...

example 2

[0023] Add peach gum and water into the beaker at a mass ratio of 1:60, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the beaker into a magnetic stirrer with digital display speed measurement and constant temperature, at a temperature of 40°C and a speed of 500r / min Under certain conditions, heat and stir to dissolve for 40 minutes to obtain peach gum solution; add coconut carbon fiber and 8% sodium hydroxide solution in a mass ratio of 1:20 into a single-necked flask, and then move the single-necked flask into a digital speed measuring constant temperature magnetic stirrer , stirred and mixed for 2 hours at a rotating speed of 500r / min to obtain a mixed solution, then filtered the mixed solution to obtain a filter cake, then washed the filter cake with deionized water for 5 times, and then placed the filter cake in a freezer pulverizer to freeze Grinding for 30 minutes to obtain the crushed material, and then drying the crushed ...

example 3

[0025]Add coconut carbon fiber and 8% sodium hydroxide solution into a single-necked flask at a mass ratio of 1:20, then move the single-necked flask into a digital display speed measuring constant temperature magnetic stirrer, and stir and mix at a speed of 500r / min for 2 hours to obtain mixed solution, and then the mixed solution was filtered to obtain a filter cake, and then the filter cake was washed 5 times with deionized water, and then the filter cake was placed in a freezer grinder for 30 minutes to freeze and pulverize to obtain a pulverized material, and then the pulverized material was placed in a vacuum Dry in a freeze-drying box for 40 minutes to obtain nano-coconut carbon fiber; by weight fraction, take 100 parts of river sand, 40 parts of Portland cement, 20 parts of fly ash, 20 parts of silica fume, 20 parts of slag, and 30 parts of water , 30 parts of silane coupling agent, 20 parts of polyallylamine aqueous solution, 20 parts of nano-coconut carbon fiber, firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com